Cationic self-extinction resin and its preparation method and application

A cationic, self-extinguishing technology, applied in coatings, polyurea/polyurethane coatings, etc., to achieve the effect of improving poor film formation, increasing mobility and good resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

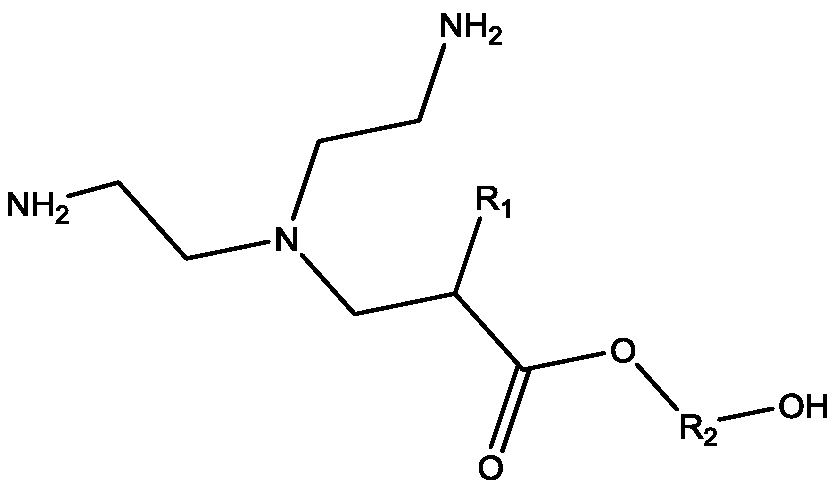

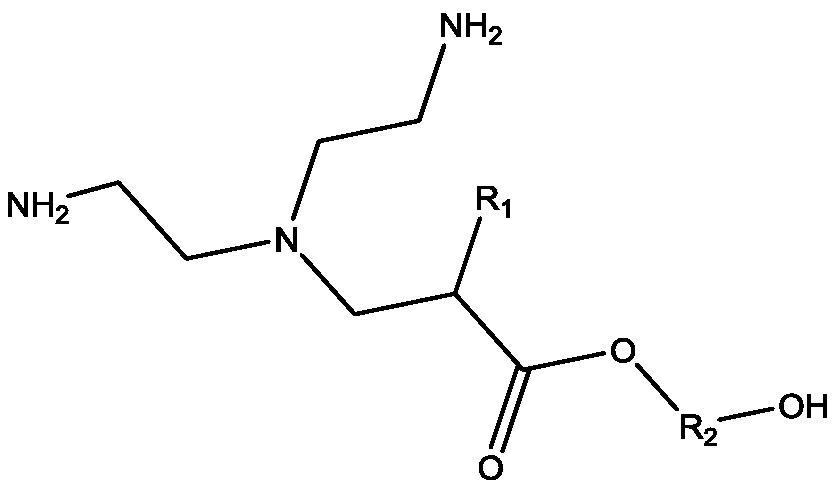

Method used

Image

Examples

Embodiment 1

[0087] A kind of cationic self-dulling resin, the weight parts of raw materials are composed of:

[0088] 7.8 parts of isocyanate (the molar ratio of IPDI to HDI is 2:1),

[0089] Macromolecule polyol (PTMG1000) 14.0 parts,

[0090] 0.11 parts of monohydric alcohol and / or dihydric alcohol (MPEG1200) containing polyoxyethylene segment in main chain and / or side chain,

[0091] 0.37 parts of diamine cationic hydrophilic chain extender (HBAAP),

[0092] Small molecule diamine chain extender (EDA and EDA-OH) 1.73 parts,

[0093] Catalyst (organic bismuth 8108) 0.0022 parts,

[0094] 32.9 parts of solvent (acetone),

[0095] 56.0 parts of deionized water,

[0096] Neutralizing agent (acetic acid) 0.1 part.

[0097] Above-mentioned cationic self-extinction resin, the preparation method is:

[0098] (1) Add 140 grams of PTMG1000 into a four-necked flask with a condenser and a stirrer, then add 31 grams of IPDI and 47 grams of HDI, 0.022g of organic bismuth 8108, 22 grams of ace...

Embodiment 2

[0104] 5.3 parts of isocyanate (IPDI, TDI, HDI),

[0105]Macromolecule polyol (PTMG1000) 11.7 parts,

[0106] 0.11 parts of monohydric alcohol and / or dihydric alcohol (MPEG1200) containing polyoxyethylene segment in main chain and / or side chain,

[0107] 0.37 parts of diamine cationic hydrophilic chain extender (HBAAP),

[0108] Small molecule diamine chain extender (EDA) 0.98 parts,

[0109] Catalyst (organic bismuth 8108) 0.00164 parts,

[0110] Solvent (acetone) 29.1 parts,

[0111] 43.1 parts of deionized water,

[0112] Neutralizing agent (acetic acid) 0.1 part.

[0113] Above-mentioned cationic self-extinction resin, the preparation method is:

[0114] (1) Add 117 grams of PTMG1000 to a four-necked flask with a condenser and a stirrer, then add 23 grams of IPDI, 6 grams of TDI and 24 grams of HDI, 0.0164 grams of organic bismuth 8108, 17 grams of acetone, and heat at 85 ° C After reacting for 1.5 hours, the NCO value was 7.3% (theoretical value was 7.36%), and a d...

Embodiment 3

[0120] 10.2 parts of isocyanate (HMDI and HDI),

[0121] Macromolecule polyol (PTMG1000) 20.0 parts,

[0122] 0.33 parts of monohydric alcohols and / or dihydric alcohols (MPEG1200) containing polyoxyethylene segments in the main chain and / or side chains,

[0123] 0.93 part of dibasic amine cationic hydrophilic chain extender (HBAAP),

[0124] Small molecule diamine chain extender (IPDA and EDA-OH) 3.2 parts,

[0125] Catalyst (organic bismuth 8108) 0.003 part,

[0126] Solvent (acetone) 51.9 parts,

[0127] 80.9 parts of deionized water,

[0128] Neutralizing agent (acetic acid) 0.254 parts.

[0129] Above-mentioned cationic self-extinction resin, the preparation method is:

[0130] (1) Add 200 grams of PTMG1000 into a four-necked flask with a condenser and a stirrer, then add 31 grams of HMDI and 71 grams of HDI, 0.03 grams of organic bismuth 8108, 31 grams of acetone, and react at 85 ° C for 1.5 hours, The NCO value is 8.7% (theoretical value is 8.61%), resulting in di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com