Ductile iron pipe with anti-corrosion inner coating and its production process

A technology for ductile iron pipes and inner coatings, applied in anti-corrosion coatings, coatings, fire-resistant coatings, etc., can solve the problems that epoxy coatings cannot meet the anti-corrosion and wear resistance, and achieve energy saving and frictional resistance reduction , the effect of increasing the crosslink density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] The ductile iron pipe used in the epoxy ceramic coating anti-corrosion inner coating of the water pipeline is prepared by the following method. The preparation method comprises the following steps:

[0067] (1) Internal grinding of ductile iron pipe;

[0068] (2) Sand blast or shot blast the inner wall of the ductile iron pipe to make the roughness Rz≥60μm;

[0069] (3) Preheating, so that the temperature of the ductile iron pipe is between 30°C and 70°C;

[0070] (4) For the repair of defects such as slag pits on the inner wall, use the high-performance epoxy ceramic coating used, add an appropriate amount of ceramic powder, and adjust to an appropriate viscosity to repair surface defects;

[0071] (5) The pipe rotates at a certain speed, and the rotational speed is a linear speed ≥ 250m / min;

[0072] (6) The high-performance phenolic epoxy ceramic coating has a high viscosity at room temperature and must be preheated: both components A and B need to be preheated to...

Embodiment 1

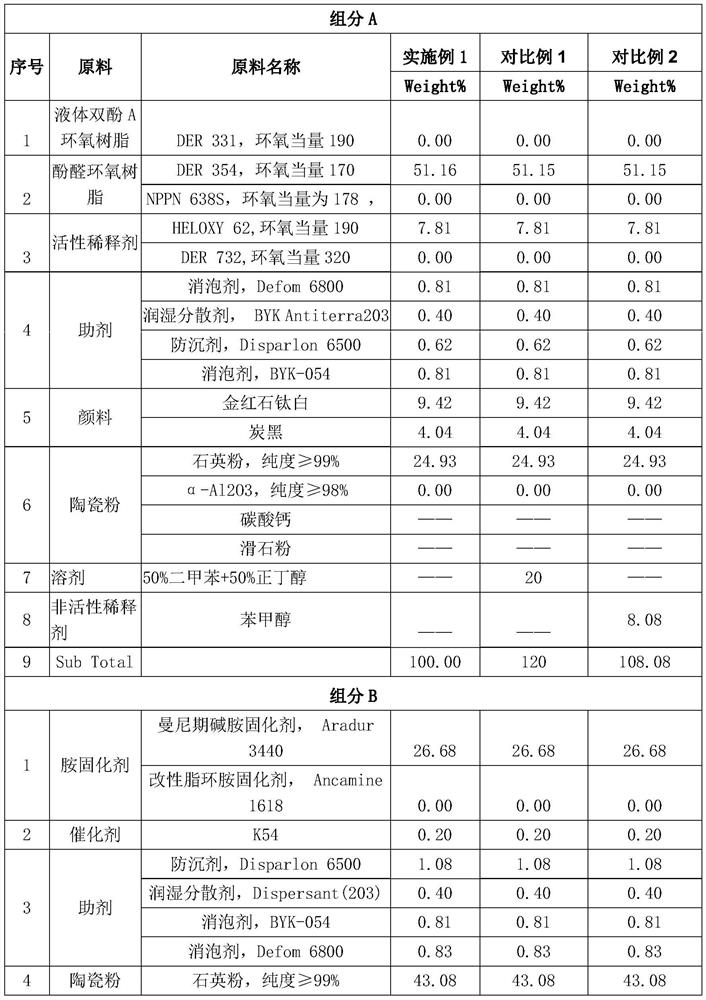

[0082] According to the method of the preparation example, the coating materials given below were prepared and coated, and the effects were compared after coating. Coating materials different from the coating materials given in the present invention can be prepared according to methods similar to the present invention according to conventional techniques in the art.

[0083] Table 1

[0084]

[0085]

Embodiment 2

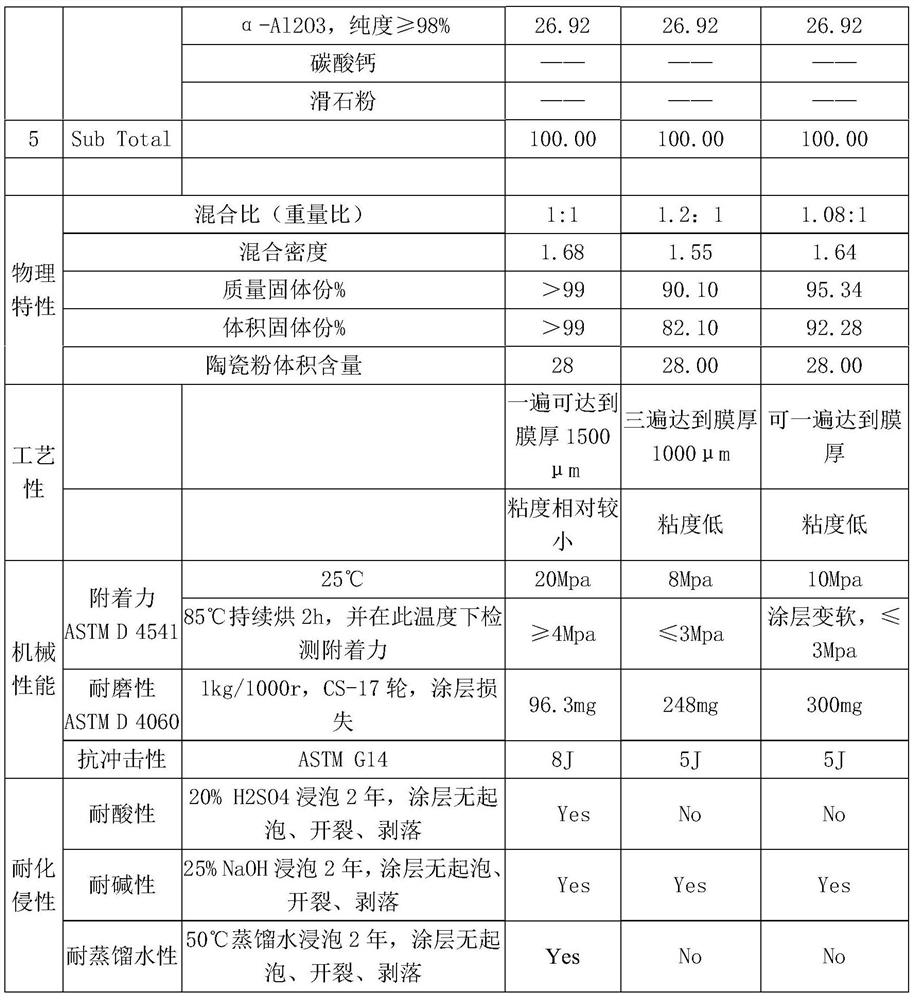

[0088] Table 2

[0089]

[0090]

[0091]

[0092] What comparative examples 3 and 4 use is the coating that conventionally uses ceramic powder in the prior art. But it can be seen that the conventionally used ceramic powder has a large inconvenient operability in the preparation process, and the existing ceramic powder calcium carbonate is easy to react with other substances (such as acidic substances), and is not resistant to the erosion of strong corrosive media. Can affect the acid resistance and water resistance of coating; Talcum powder, calcium carbonate are relatively low in hardness to the high-purity ceramic powder material required by the present invention, so they are obviously weaker than the coating used in the present invention aspect mechanical properties and chemical resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com