Full-inorganic perovskite solar energy cell prepared based on spray auxiliary method and preparation method and application of full-inorganic perovskite solar energy cell

A technology of solar cells and inorganic calcium, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of unfavorable large-scale commercial application and small device area, so as to improve the photoelectric conversion efficiency, stability, and repeatability. The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

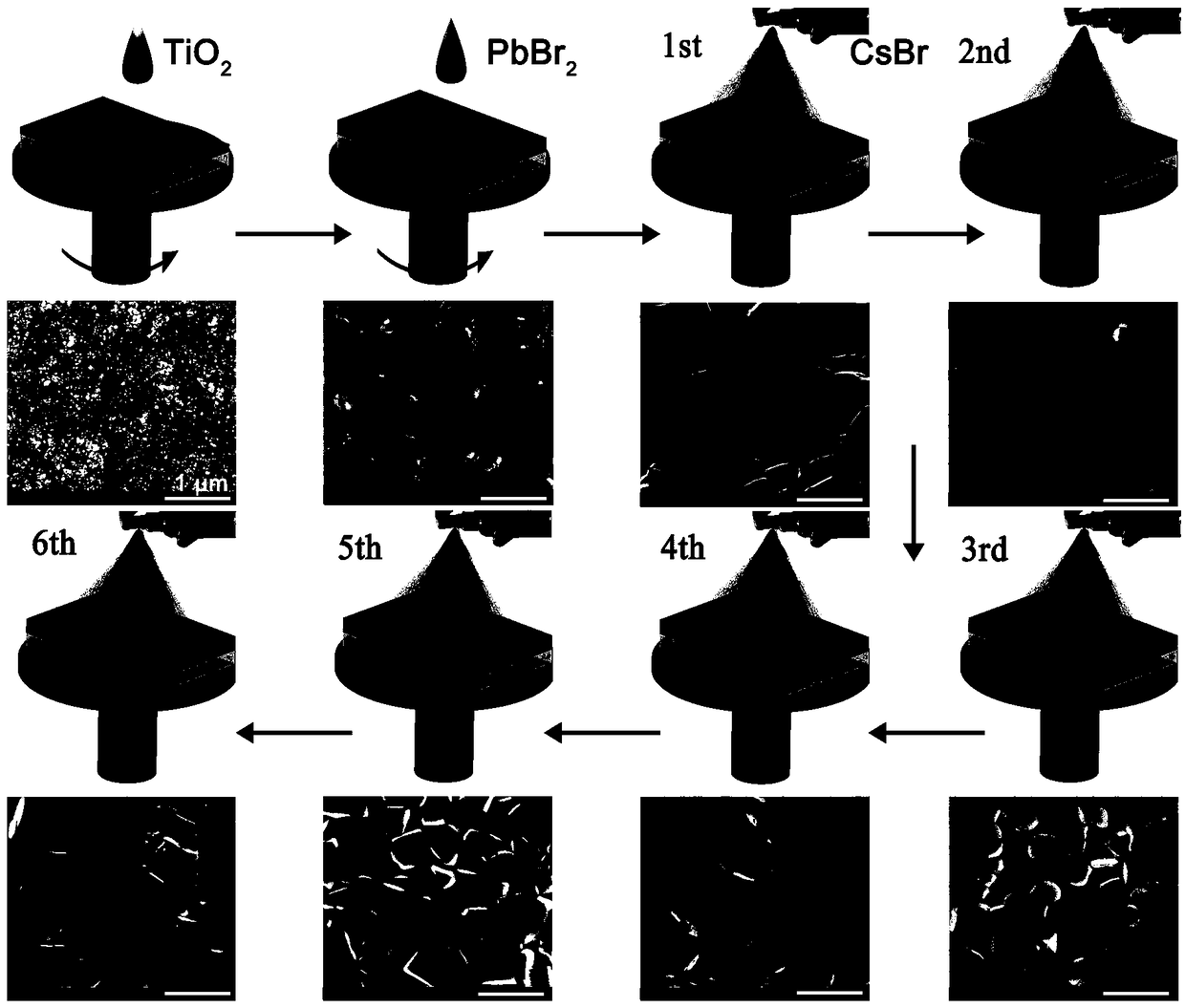

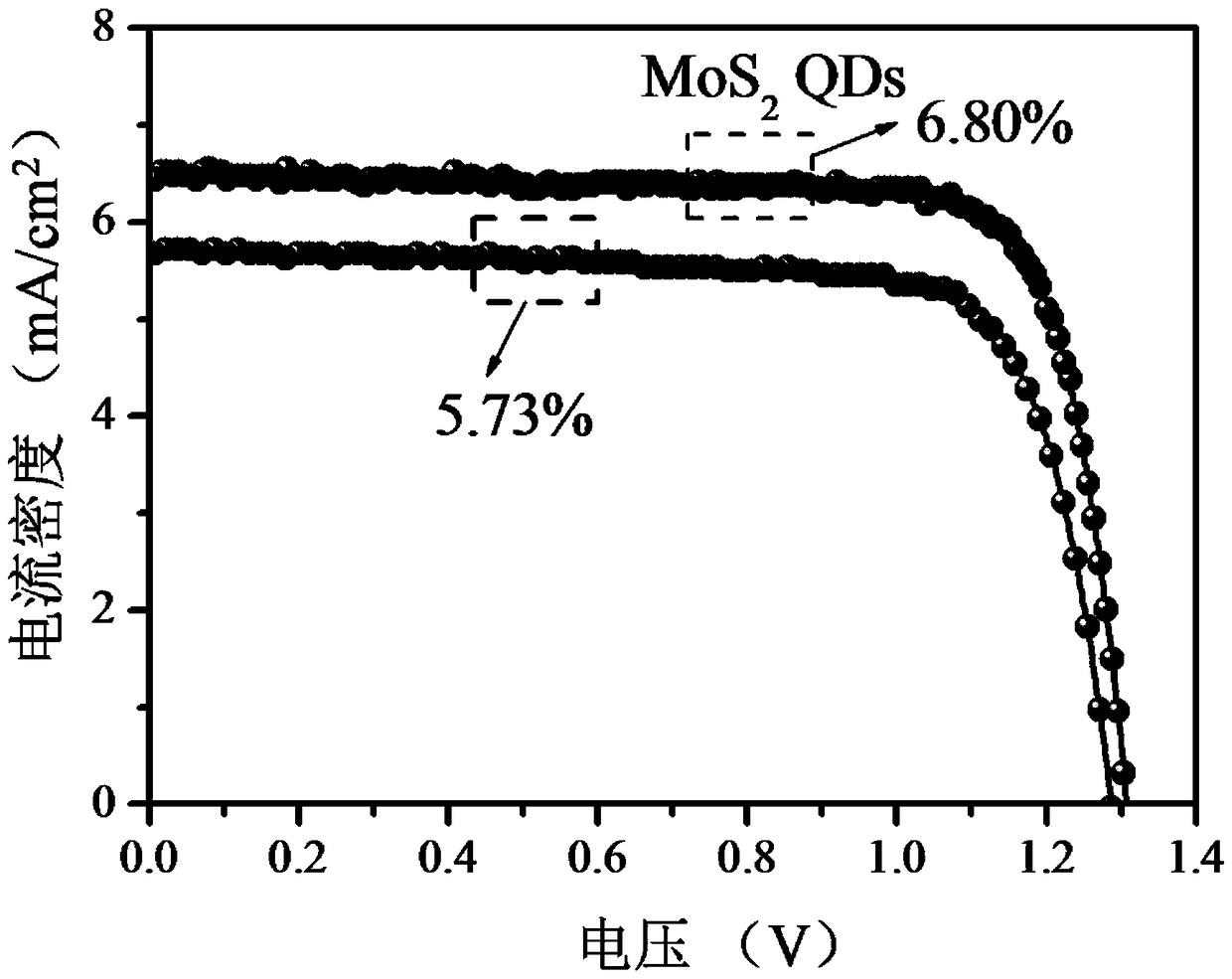

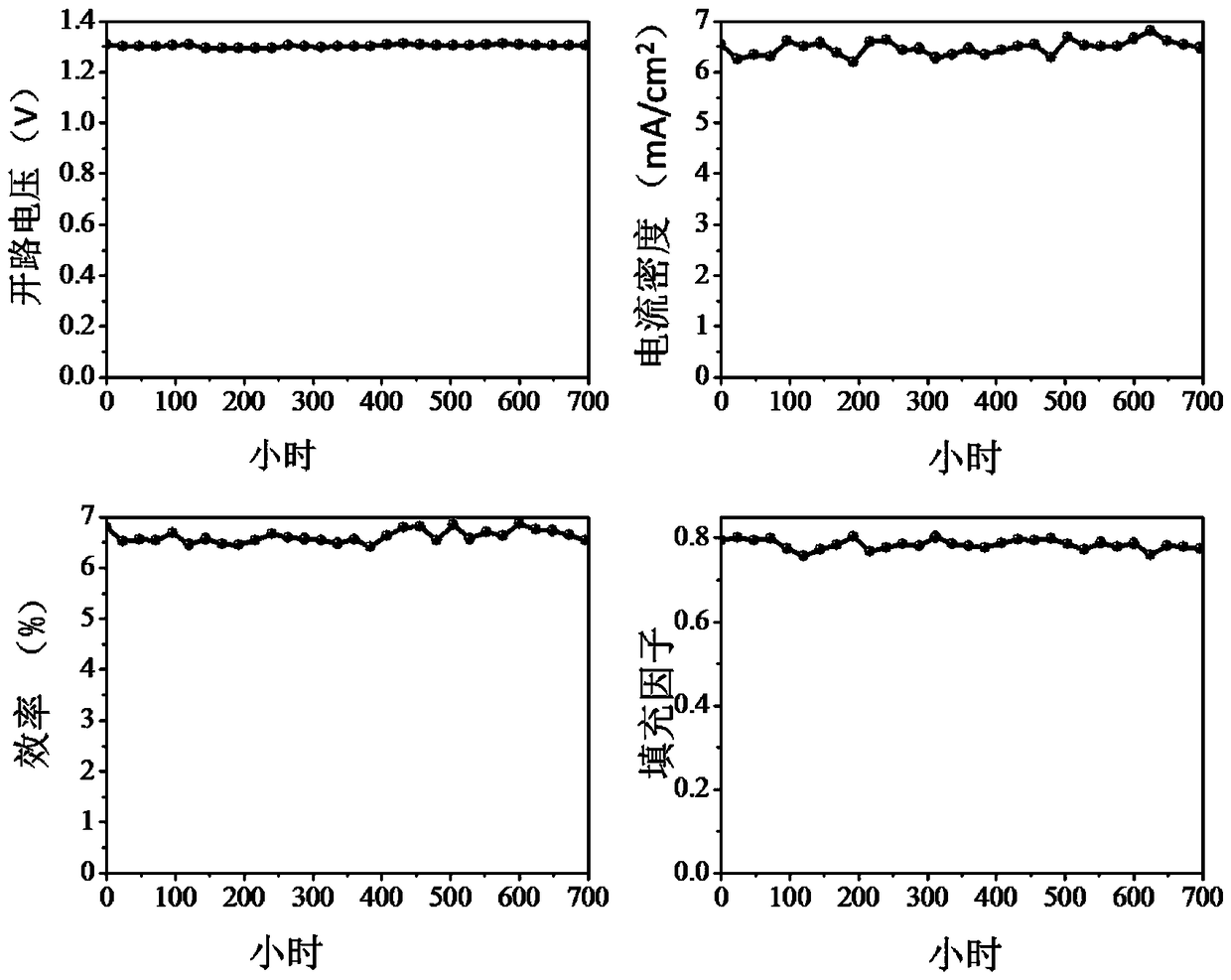

[0035] The preparation method of the all-inorganic perovskite solar cell prepared based on the spray-assisted method of the present invention comprises the following steps:

[0036] 1. Dissolve 1 g of molybdenum disulfide nanopowder in 100 mL of dimethylbenzylamine solution (mass concentration ≥ 98%); prepare molybdenum disulfide dispersion;

[0037] 2. After stirring the molybdenum disulfide dispersion evenly, ultrasonically disperse it for 4-6 hours, and take the supernatant after standing;

[0038] 3. Put the supernatant in a three-way flask, stir and heat at 120-140°C for 4-6 hours, and centrifuge to remove the residue to obtain a uniformly distributed molybdenum disulfide quantum dot solution;

[0039] 4. Prepare an ethanol solution of isopropyl titanate with a concentration of 0.1-1 mol / L, a titanium dioxide slurry with a solubility of 0.05-0.1 g / mL, and an aqueous solution of titanium tetrachloride with a concentration of 0.01-0.05 mol / L ; Preparation concentration is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com