Rose-shaped vanadium disulfide/carbon quantum-dot composite material and preparation method and application thereof

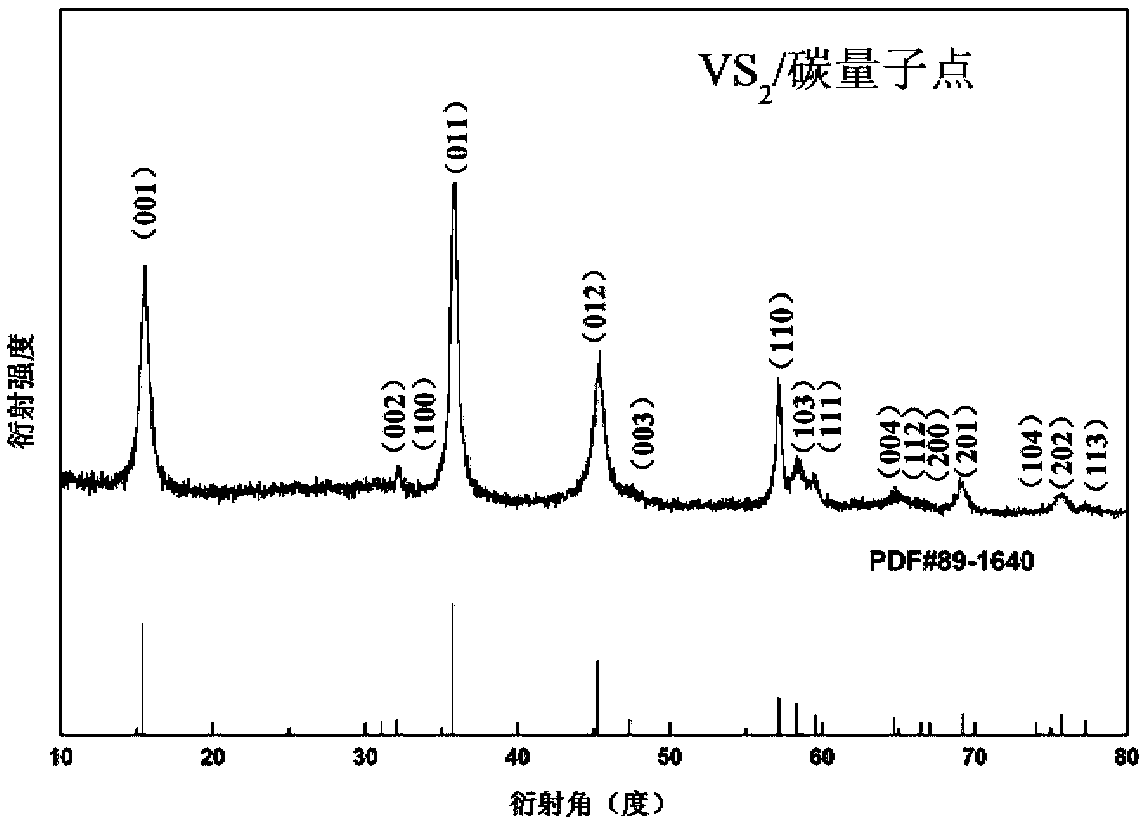

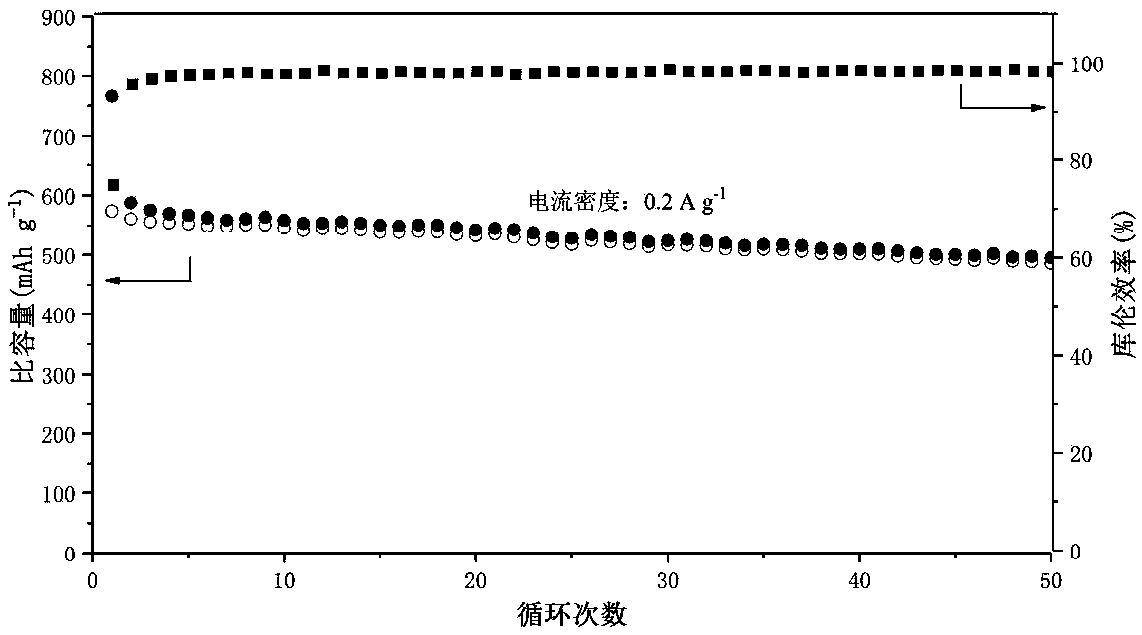

A technology of carbon quantum dots and vanadium disulfide, which is applied to a composite material with rose-shaped vanadium disulfide/carbon quantum dots and its preparation, and the application field of sodium ion batteries, which can solve the problem of capacity decay, poor rate performance, and volume change. and structural collapse, etc., to achieve the effect of short diffusion distance, many active sites, and special structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Add 1.0g of sodium hydroxide to a mixed solution of 10ml of deionized water and 150ml of ethanol, use a three-way high-precision regulated power supply produced by Shenzhen Dingyang Technology Co., Ltd. for electrolysis, set the voltage at 20V, and electrolysis for 20 hours. The electrolyzed solution was dialyzed and evaporated to dryness at 70°C. That is, carbon quantum dots are obtained.

[0050] Add 2 mmol of ammonium metavanadate and 16 mmol of thioacetamide into 30 mL of deionized water, and stir until uniform at room temperature. Add 0.5 g of polyvinylpyrrolidone with a molecular weight of 48,000 and 0.5 g of carbon quantum dots into the aforementioned solution, and stir until uniform to obtain a mixed solution A. Add 5mL of ethylene glycol into the mixed solution A, mix well to obtain the mixed solution B, transfer the mixed solution B to a 50mL hydrothermal reaction kettle, and conduct a hydrothermal reaction at 180°C for 12h. Then centrifuge to obtain solid p...

Embodiment 2

[0054] Add 1.0g of lithium hydroxide to a mixed solution of 10ml of deionized water and 150ml of ethanol, use a three-way high-precision regulated power supply produced by Shenzhen Dingyang Technology Co., Ltd. for electrolysis, set the voltage at 15V, and electrolysis for 28 hours. The electrolyzed solution was dialyzed and evaporated to dryness at 70°C. That is, carbon quantum dots are obtained.

[0055] Add 2 mmol of potassium metavanadate and 20 mmol of thioacetamide into 30 mL of deionized water, and stir until uniform at room temperature. 0.5 g of polyvinylpyrrolidone with a molecular weight of 48,000 and 0.8 g of carbon quantum dots were added to the aforementioned solution, and stirred until uniform to obtain a mixed solution A. Add 10mL of ethylene glycol into the mixed solution A and mix evenly to obtain the mixed solution B, transfer the mixed solution B to a 50mL hydrothermal reaction kettle, and conduct a hydrothermal reaction at 180°C for 20h. Then centrifuged ...

Embodiment 3

[0057] Add 2.0g of sodium hydroxide to a mixed solution of 10ml of deionized water and 180ml of ethanol, use a three-way high-precision regulated power supply produced by Shenzhen Dingyang Technology Co., Ltd. for electrolysis, set the voltage at 15V, and electrolysis for 28 hours. The electrolyzed solution was dialyzed and evaporated to dryness at 90°C. That is, carbon quantum dots are obtained.

[0058] Add 2 mmol of sodium orthovanadate and 10 mmol of thioacetamide into 20 mL of deionized water, and stir until uniform at room temperature. 0.5 g of polyvinylpyrrolidone with a molecular weight of 48,000 and 0.8 g of carbon quantum dots were added to the aforementioned solution, and stirred until uniform to obtain a mixed solution A. Add 15mL of isopropanol to the mixed solution A and mix evenly to obtain the mixed solution B, transfer the mixed solution B to a 50mL hydrothermal reaction kettle, and conduct a hydrothermal reaction at 180°C for 36h. Then centrifuge to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com