Bioactive water for improving effects of traditional Chinese medicine, and production technology thereof

A technology of biologically active water and production process, applied in the field of water treatment, can solve the problems of low extraction efficiency, high pollution and high energy consumption of traditional Chinese medicine, and achieve the effects of fast movement, improved extraction efficiency and improved drug efficacy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The production process of biologically active water used to improve the efficacy of traditional Chinese medicines comprises the following steps:

[0063] (1) Get the spring water of the natural water source: the natural water source is the Guangxi Bama area located in the northwest of Guangxi;

[0064] (2) Quartz sand filtration: filter the spring water from the natural water source through a mechanical filter, the mechanical filter is a cylindrical stainless steel structure with an effective volume of 0.6m 3 , with a diameter of 0.8m, using quartz sand as the filter medium, the height of the quartz sand filter layer is 1.2m, the working pressure is 0.3MPa, the working temperature is 40°C, and the filtration speed is 10m 3 / h;

[0065] (3) Activated carbon filtration: filter the water out of quartz sand, use activated carbon as the filter medium, and filter at a speed of 10m 3 / h, obtain the water after step (3) treatment;

[0066] (4) softening treatment: the water ...

Embodiment 2

[0076] The production process of biologically active water used to improve the efficacy of traditional Chinese medicines comprises the following steps:

[0077] (1) Get the spring water of the natural water source: the natural water source is the Guangxi Bama area located in the northwest of Guangxi;

[0078] (2) Quartz sand filtration: filter the spring water from the natural water source through a mechanical filter, use quartz sand as the filter medium, work at a pressure of 0.3MPa, work at a temperature of 40°C, and filter at a speed of 10m 3 / h;

[0079] (3) activated carbon filtration: the water treated in step (2) is filtered with activated carbon as a medium, and the activated carbon adsorption filter is filtered, and the filtration speed is 10m 3 / h, obtain the water after step (3) treatment.

[0080] The preparation method of described activated carbon comprises the following steps, and described part is weight:

[0081] (1) Pulverize the bamboo slices, pass throug...

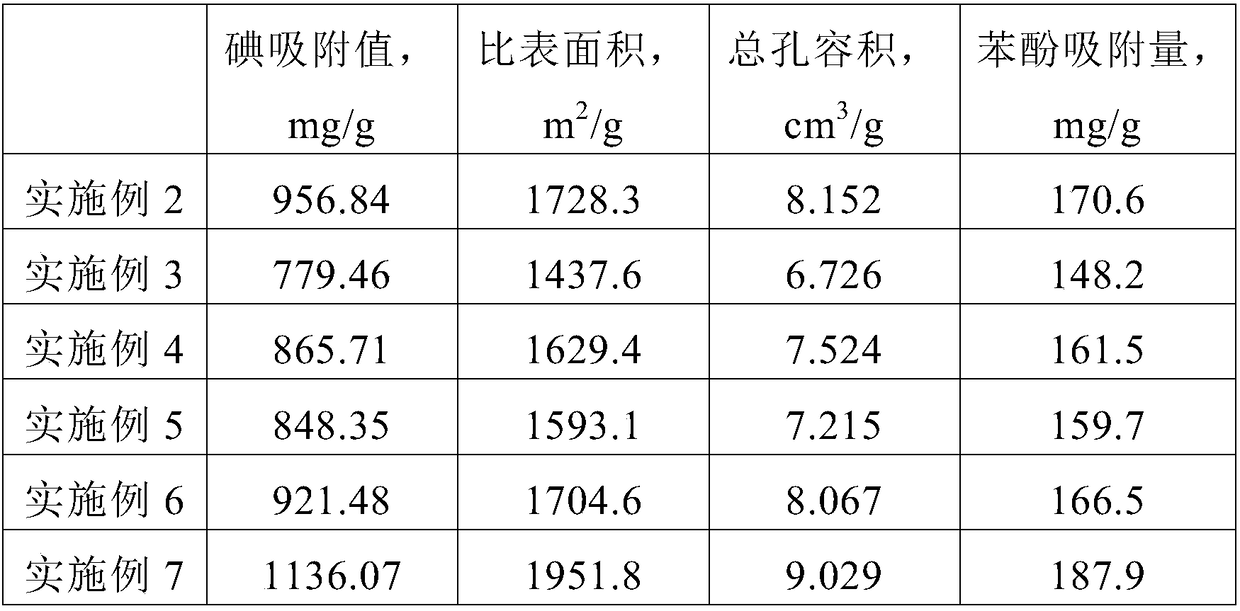

Embodiment 3

[0100]It is basically the same as Embodiment 2, the only difference is:

[0101] The preparation method of described activated carbon comprises the following steps, and described part is weight:

[0102] (1) Pulverize the bamboo slices, pass through a 40-mesh sieve, and dry at 100°C for 4 hours to obtain coarse bamboo slice powder. Mix the coarse bamboo slice powder and activator at a solid-to-liquid ratio of 1g: 8mL, soak for 150 minutes, and use 500 mesh filter cloth, the solid obtained is the impregnated bamboo chip meal;

[0103] (2) Put the impregnated bamboo chip coarse powder into a tube furnace, under the protection of nitrogen, raise the temperature to 500°C at 10°C / min, keep it warm for 80 minutes, and naturally cool down to 25°C to obtain the initial carbonization material;

[0104] (3) Put the primary carbonization material into a tube furnace, under the protection of nitrogen, raise the temperature to 700 °C at 10 °C / min, keep the temperature for 60 minutes, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com