Aqueous coating for automobile plastic part

A technology of water-based paint and plastic parts, applied in the direction of coating, etc., can solve the problems of environmental impact of waste, damage of plastic film parts, increased cost, etc., and achieve the effects of reducing pretreatment steps, protecting the environment, and good acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0024]

[0025]

[0026] The first resin is polyacrylic acid dispersion containing hydroxyl functional groups, high solid content and high molecular weight (about 830g / mol), solid content 40 ± 2%, pH value 8 ± 0.5, add 15-25 parts of water to dilute , mixed with aliphatic polyisocyanate, can prepare room temperature drying or 80 ℃ forced drying high-gloss topcoat, the cured paint film is tough, and the single-coat adhesion is good, and has good water resistance and solvent resistance. The second resin is a hydroxyl polyacrylic acid dispersion, the solid content is about 42%, the hydroxyl content is about 2%, and the pH value is 7.7±0.5. The rheological additive is organically modified montmorillonite clay Similar rheological additives, density 1.73 (g / cm3), model B38, purchased from Xiamen Kangdilong Trading Co., Ltd. The film-forming aid is one or both of dipropylene glycol methyl ether or dipropylene glycol monobutyl ether. The anti-flash rust agent, model YF-1207, is...

Embodiment 5

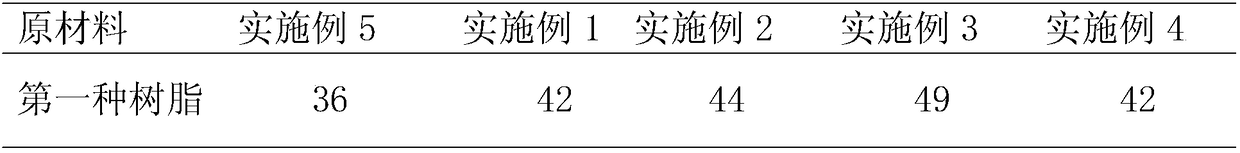

[0028] Embodiment 5 coating is in the following table 1 in each plastic substrate surface mechanical performance test result:

[0029] Table 1

[0030]

[0031]

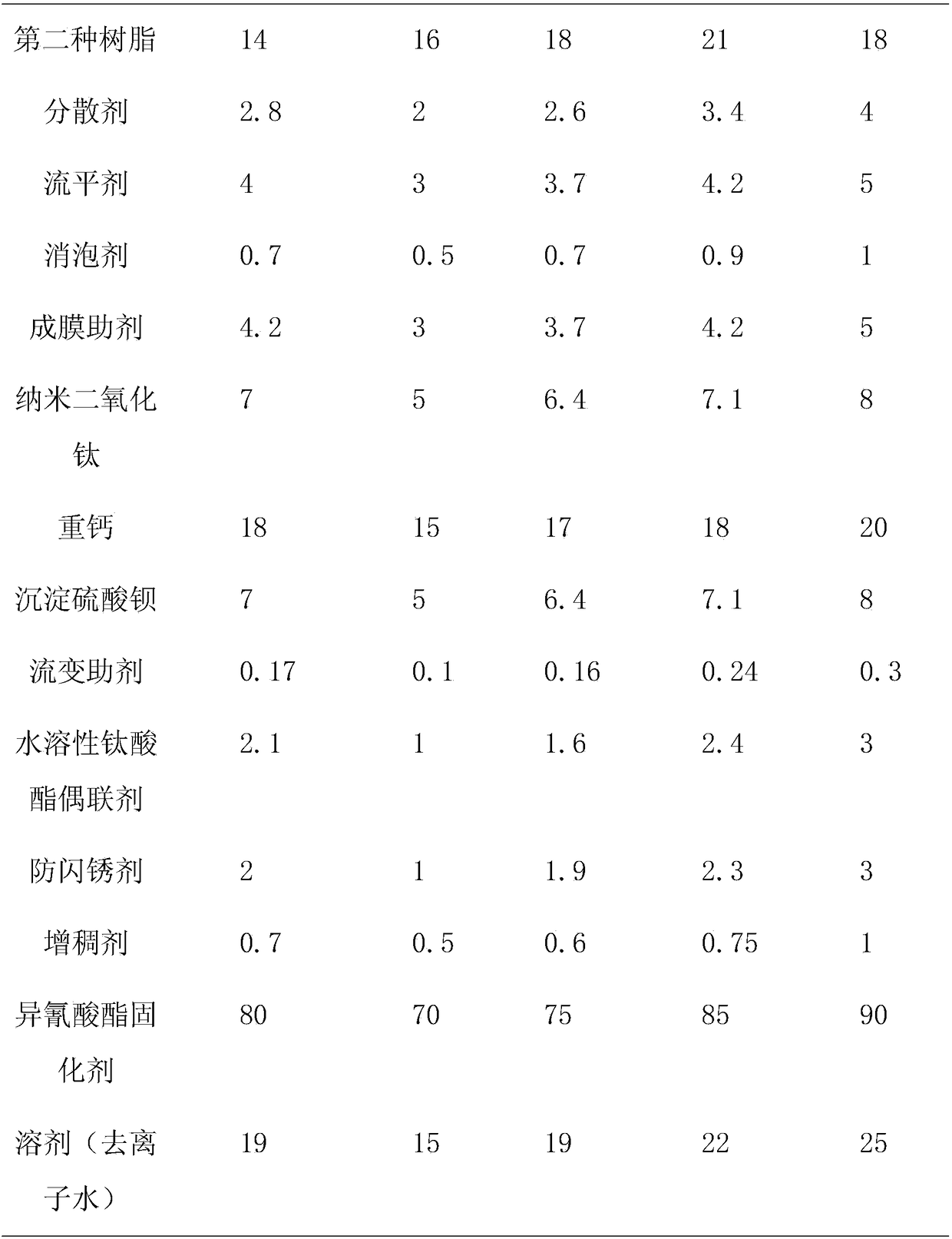

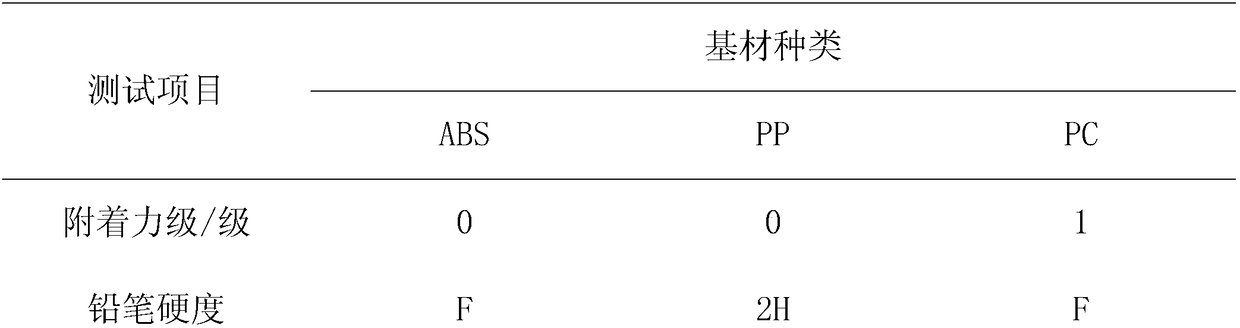

[0032] Product detection performance is as follows table 2 (embodiment 5):

[0033] Table 2

[0034]

[0035] It can be seen from Table 1 that the coating has good adhesion to ABS, PP, and PC, and has good hardness, and the wear resistance can also meet the standard, which can meet the performance requirements of the surface coating of plastic materials. Select PP material surface coating to do further performance test, table 2 is water-based polyurethane coating of the present invention coated on PP material and other performance index inspection results, as can be seen from the table has high storage stability, coating surface gloss It has good performance of water boiling resistance and chemical corrosion resistance. It can provide good protection for automotive plastic parts and meet the requirements o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com