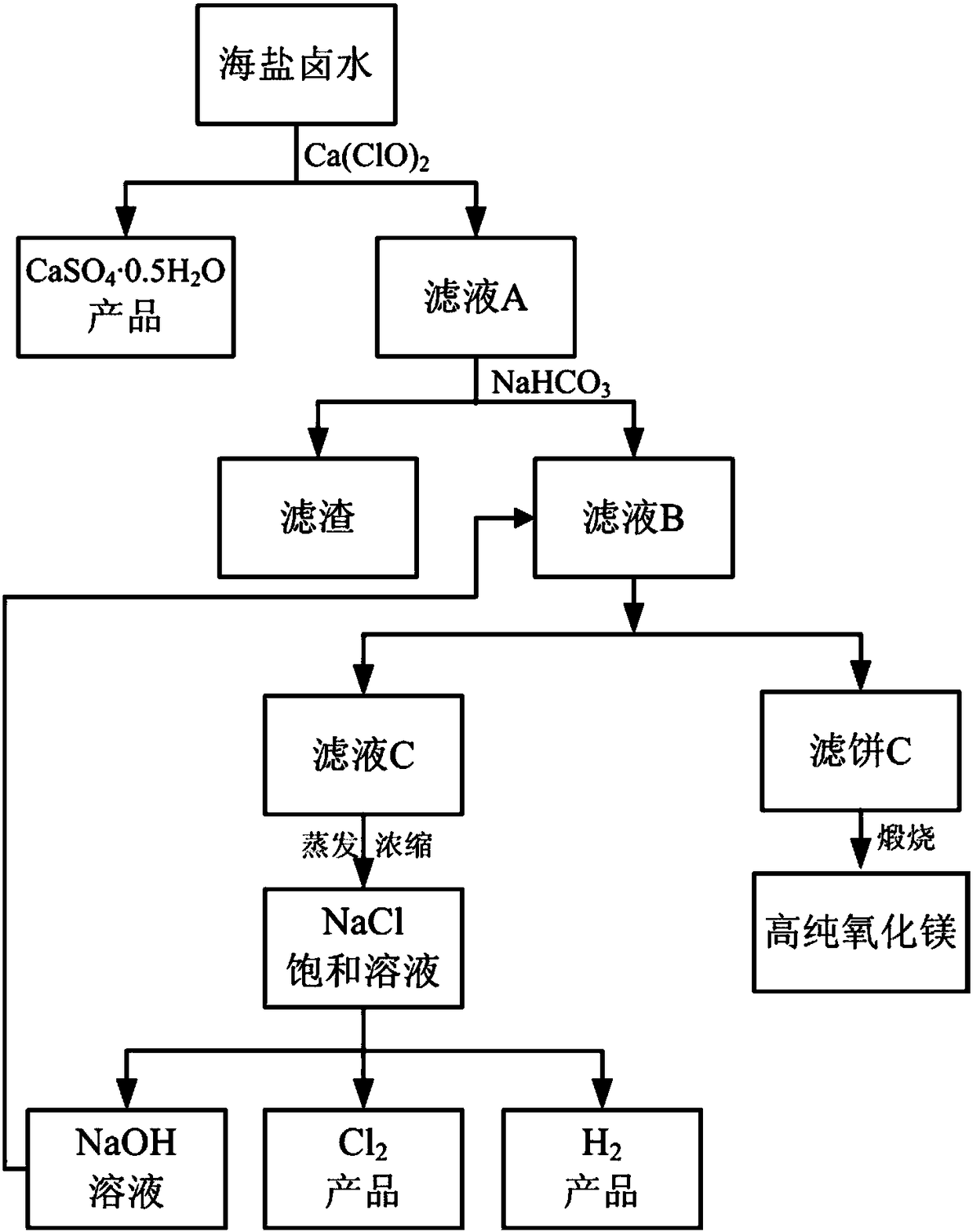

Preparation method of high-purity magnesium oxide from sea salt brine

A magnesium oxide and brine technology, applied in the direction of magnesium oxide, calcium/strontium/barium sulfate, electrolysis process, etc., can solve the problems of poor economic benefit, low product added value, utilization rate less than 20%, and achieve product yield High, enhance value, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A method for preparing high-purity magnesium oxide using sea salt brine as raw material, the technical scheme is carried out according to the following steps:

[0058] step 1:

[0059] Pump the sea salt brine to the reaction kettle, preheat the sea salt brine, set the reaction temperature to 50°C, and the reaction time to 60 minutes;

[0060] Step 2:

[0061] Add calcium hypochlorite to sea salt brine for decolorization reaction and stir, the weight ratio of calcium hypochlorite to sea salt brine is 1:2%, the reaction temperature is set at 50°C, and the stirring rate during the reaction is 480r / min. The reaction time is 1.5h. After the reaction is over, filter the slurry in the reactor to obtain filtrate A and filter cake A. The filter cake A is the decolorization residue, and the main component of the decolorization residue is CaSO 4 0.5H 2 O, can be sold directly as a by-product;

[0062] Step 3:

[0063] Pump the filtrate A to the reactor, add sodium bicarbonate...

Embodiment 2

[0073] A method for preparing high-purity magnesium oxide using sea salt brine as raw material, the technical scheme is carried out according to the following steps:

[0074] step 1:

[0075] Pump the sea salt brine to the reaction kettle, preheat the sea salt brine, set the reaction temperature to 60°C, and the reaction time to 50 minutes;

[0076] Step 2:

[0077] Add calcium hypochlorite to sea salt brine for decolorization reaction and stir. The weight ratio of calcium hypochlorite to sea salt brine is 1:1%, the reaction temperature is set at 70°C, and the stirring rate during the reaction is 360r / min. The reaction time is 1h. After the reaction, the slurry in the reactor is filtered to obtain the filtrate A and the filter cake A. The filter cake A is the decolorization residue, and the main component of the decolorization residue is CaSO 4 0.5H 2 O, can be sold directly as a by-product;

[0078] Step 3:

[0079] Pump the filtrate A to the reactor, add sodium bicarbon...

Embodiment 3

[0089] A method for preparing high-purity magnesium oxide using sea salt brine as raw material, the technical scheme is carried out according to the following steps:

[0090] step 1:

[0091] Pump the sea salt brine to the reaction kettle, preheat the sea salt brine, set the reaction temperature to 70°C, and the reaction time to 35 minutes;

[0092] Add calcium hypochlorite to sea salt brine for decolorization reaction and stir. The weight ratio of calcium hypochlorite to sea salt brine is 1:1%, the reaction temperature is set at 70°C, and the stirring rate during the reaction is 360r / min. The reaction time is 1h. After the reaction, the slurry in the reactor is filtered to obtain the filtrate A and the filter cake A. The filter cake A is the decolorization residue, and the main component of the decolorization residue is CaSO 4 0.5H 2 O, can be sold directly as a by-product;

[0093] Step 3:

[0094] Pump the filtrate A to the reaction kettle, add sodium bicarbonate to the...

PUM

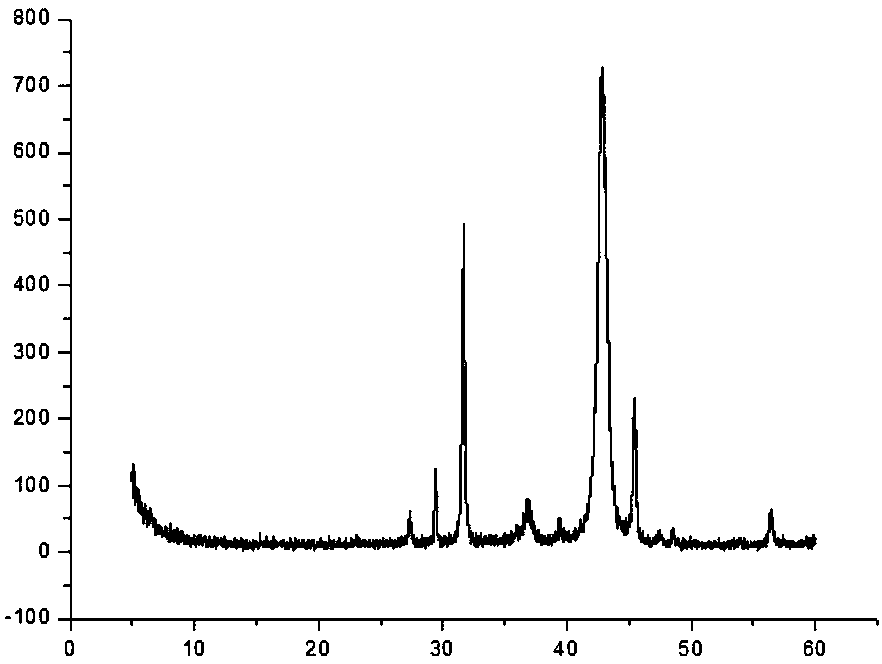

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap