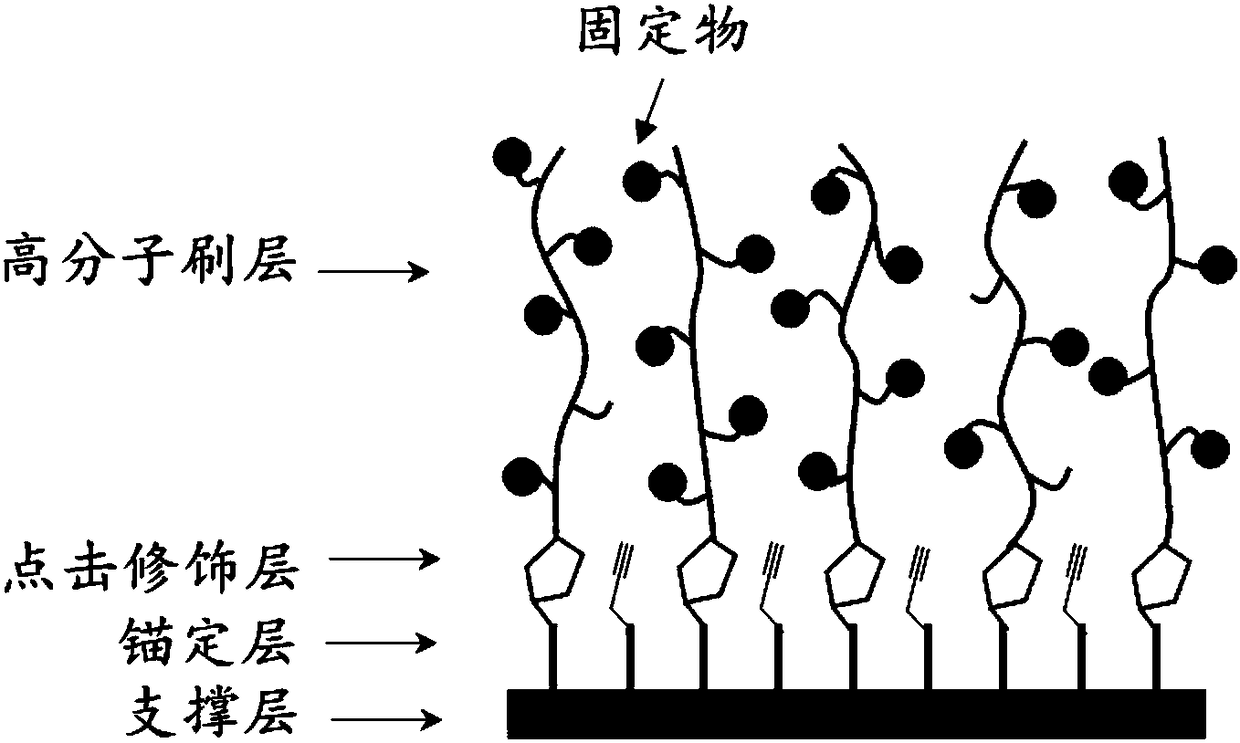

Biological sensing three-dimensional chip and preparation method thereof

A biosensing, three-dimensional chip technology, applied in the field of biological analysis, can solve the problems of low sample load, limited diversity and application of three-dimensional biosensing chip, weak specificity, etc. Controlled, specific effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

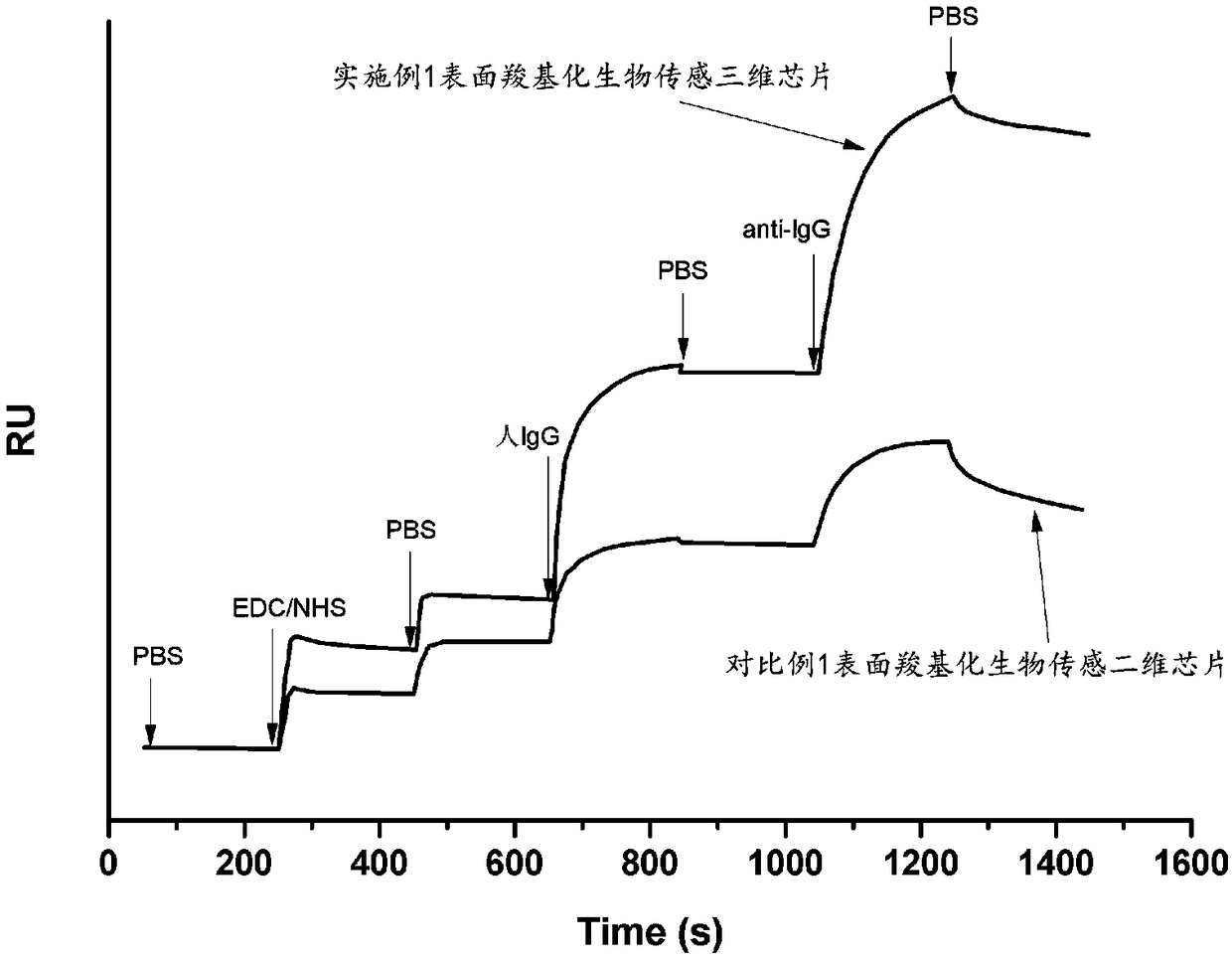

Examples

Embodiment 1

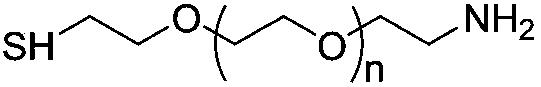

[0038] (1) Put the glass substrate coated with gold film in a plasma cleaner for 10 minutes, and soak the cleaned gold-coated glass substrate in an ethanol solution with a total concentration of 1 mM anchoring agent (molecular weight is about 400) , driven by self-assembly, a self-assembled monomolecular anchor layer is formed on the surface of the substrate;

[0039] (2) soak the substrate containing the self-assembled monomolecular anchoring layer obtained in step (1) in the ethyl acetate solution of 3-bromopropyne, react at room temperature for 6 hours, clean the chip, and obtain the surface alkynyl functional group Modified substrates;

[0040] (3) In a reaction flask, add 0.01 molar portion of ethyl bromoisobutyrate, 1 molar portion of polyethylene glycol methacrylate monomer and 1 molar portion of hydroxyethyl methacrylate monomer, 0.01 molar parts of copper chloride, 0.01 molar parts of sodium ascorbate, 100 molar parts of methanol and 100 molar parts of deionized wate...

Embodiment 2

[0045] (1) Put the silver-coated glass substrate in a plasma cleaning machine to clean for 10 minutes, soak the cleaned gold-plated glass substrate in an ethanol solution of anchoring agent (molecular weight is about 1000) with a total concentration of 10mM , driven by self-assembly, a self-assembled monomolecular anchor layer is formed on the surface of the substrate;

[0046](2) soak the substrate containing the self-assembled monomolecular anchoring layer obtained in step (1) in a dimethyl sulfoxide (DMSO) solution of 6-bromohexyne, react at room temperature for 24 hours, and clean the chip. Obtain a substrate modified with alkynyl functional group on the surface;

[0047] (3) In a reaction bottle, add 0.02 molar parts of ethyl 2-bromoisobutyrate, 1 molar part of polyethylene glycol methacrylate monomer and 2 molar parts of hydroxyethyl methacrylate monomer, 0.03 molar parts of copper chloride, 0.03 molar parts of sodium ascorbate, 300 molar parts of methanol and 100 molar...

Embodiment 3

[0052] (1) Put the glass substrate coated with gold film in the plasma cleaning machine for cleaning for 10 minutes, soak the cleaned gold-plated glass substrate in the ethanol solution of anchoring agent (molecular weight is about 10000) with a total concentration of 5mM , driven by self-assembly, a self-assembled monomolecular anchor layer is formed on the surface of the substrate;

[0053] (2) Soak the substrate containing the self-assembled monomolecular anchoring layer obtained in step (1) in a tetrahydrofuran (THF) solution of 4-chloro-n-butyne, react at room temperature for 16 hours, clean the chip, and obtain the surface alkyne Substrates modified with functional groups;

[0054] (3) In a reaction flask, add 0.005 molar parts of ethyl 2-bromoisobutyrate, 1 molar part of polyethylene glycol methacrylate monomer and 3 molar parts of hydroxyethyl methacrylate monomer, 0.1 molar parts of copper chloride, 0.1 molar parts of sodium ascorbate, 200 molar parts of methanol and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com