Preparation method and application of bacilli for efficiently metabolizing glycerol

A Bacillus and Bacillus licheniformis technology, applied in the fields of genetic engineering and microorganisms, can solve the problems of slow glycerol metabolism and achieve the effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Construction of Bacillus licheniformis ccpC Knockout Vector

[0025] Step 1: According to the upstream and downstream sequences of the ccpC gene (shown in SEQ ID NO.1) in the Bacillus licheniformis WX-02 genome DNA sequence, design the upstream homology arm primers (A-F and A-R) and the downstream homology of the ccpC gene Arm primers (B-F and B-R); and using the genomic DNA of Bacillus licheniformis WX-02 as a template, carry out PCR amplification with the upstream homology arm primers and downstream homology arm primers of the ccpC gene respectively to obtain the upstream homology arms of the ccpC gene (833bp) and the downstream homology arm of the ccpC gene (885bp);

[0026] Among them, the sequence of A-F, A-R, B-F, B-R is:

[0027] A-F: GCTCTAGAAAATGTGGATAGCCTGAC,

[0028] A-R: GAGTCCTGCCTTTTCTAGTGTGGACATTCCTCATTCCAATAAGT,

[0029] B-F: ACTTATTGGAATGAGGAATGTCCACACTAGAAAGGCAGGACTC,

[0030] B-R: TGCGAGCTCCAAAGCCGTCCGTTTCTCC;

[0031] Step 2: Link the upstream h...

Embodiment 2

[0037] Construction of ccpC knockout strain:

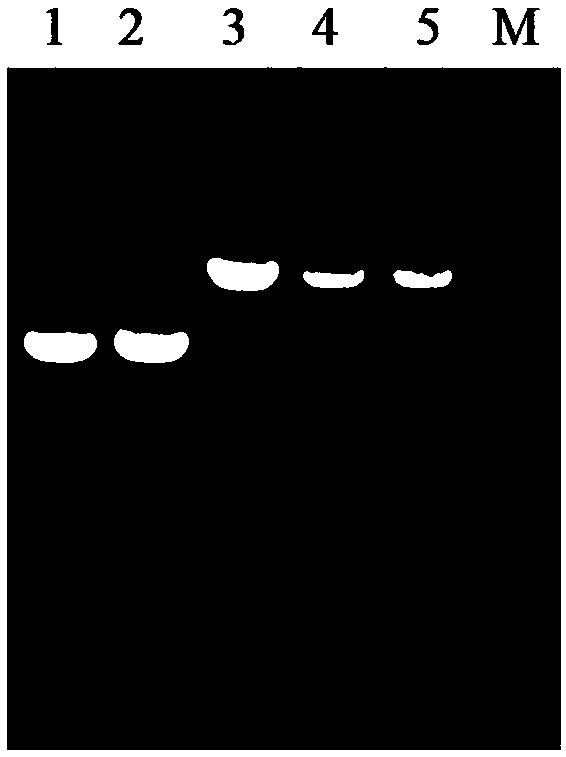

[0038]Step 1: Transform the integrated expression vector T2(2)-ccpC into Bacillus licheniformis WX-02, screen under the condition of 37°C in a culture medium containing kanapenicillin resistance, and obtain transformants by screening, and transformants Pick the plasmid for colony PCR verification (the primers used are: T2-F and T2-R). If the PCR verification result of the transformant is: an electrophoresis band occurs at 1918bp, it proves that the integrated expression vector T2(2)-ccpC is successfully transferred into Bacillus licheniformis WX-02, at this time, the transformant is a positive transformant ( That is, the Bacillus licheniformis WX-02 transformed into the integrated expression vector T2(2)-ccpC);

[0039] Step 2: Transplant the positive transformants obtained in step 1 at 45°C on a medium containing kanapenicillin resistance for 3 times, each time for 12 hours, and use T2-F and ccpC-YR as primers Single-crossover ...

Embodiment 3

[0045] Efficient metabolism of glycerol by Bacillus licheniformis WX-02ΔccpC:

[0046] 1) Seed fermentation: activate Bacillus licheniformis WX-02 and Bacillus licheniformis WX-02ΔccpC on the plate, pick the bacteria and inoculate them into 250mL Erlenmeyer flasks containing 50mL liquid LB respectively, and culture at 37°C and 180rpm for 10h. Then subsequently inoculate in the fermentation medium with an inoculum size of 1% (volume ratio);

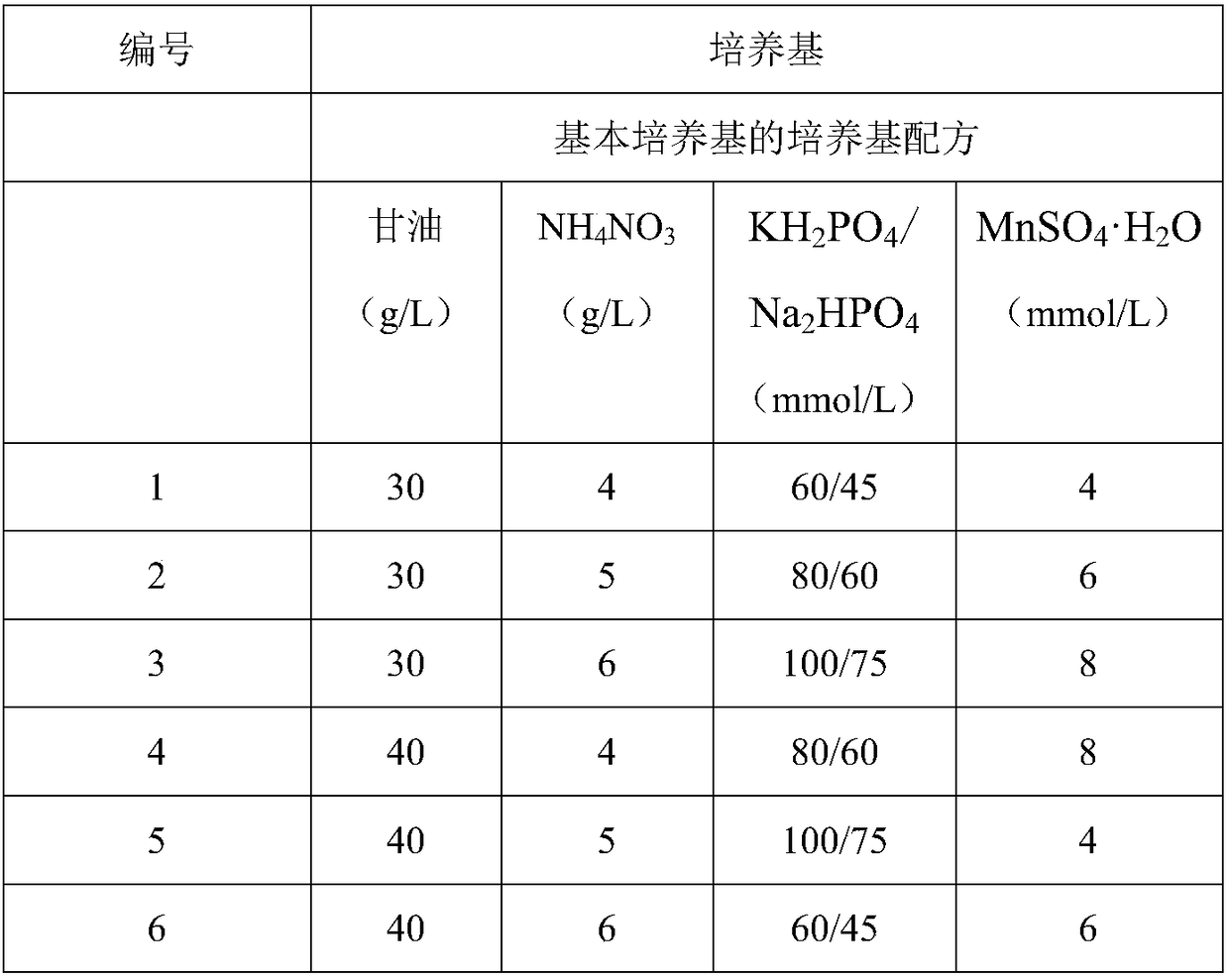

[0047] The applicant selected two culture medium formulations for the fermentation medium, the number 1-9 is the basic medium, and the number 10-18 is the poly-γ-glutamic acid fermentation medium (Table 1).

[0048] The culture condition of the basic medium is 37° C., 180 rpm for 24 hours.

[0049] The culture condition of the poly-γ-glutamic acid fermentation medium was 37° C., 180 rpm for 48 hours, and the concentration of glycerol was measured after the fermentation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com