Lithium ion battery negative electrode material FeS/Fe/C and preparation method thereof

A technology of lithium-ion batteries and negative electrode materials, which is applied in the direction of battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., can solve the need to improve electrochemical performance, not solve the defects of ferrous sulfide, High preparation cost and other problems, to achieve the effect of improving electrochemical performance, increasing conductivity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

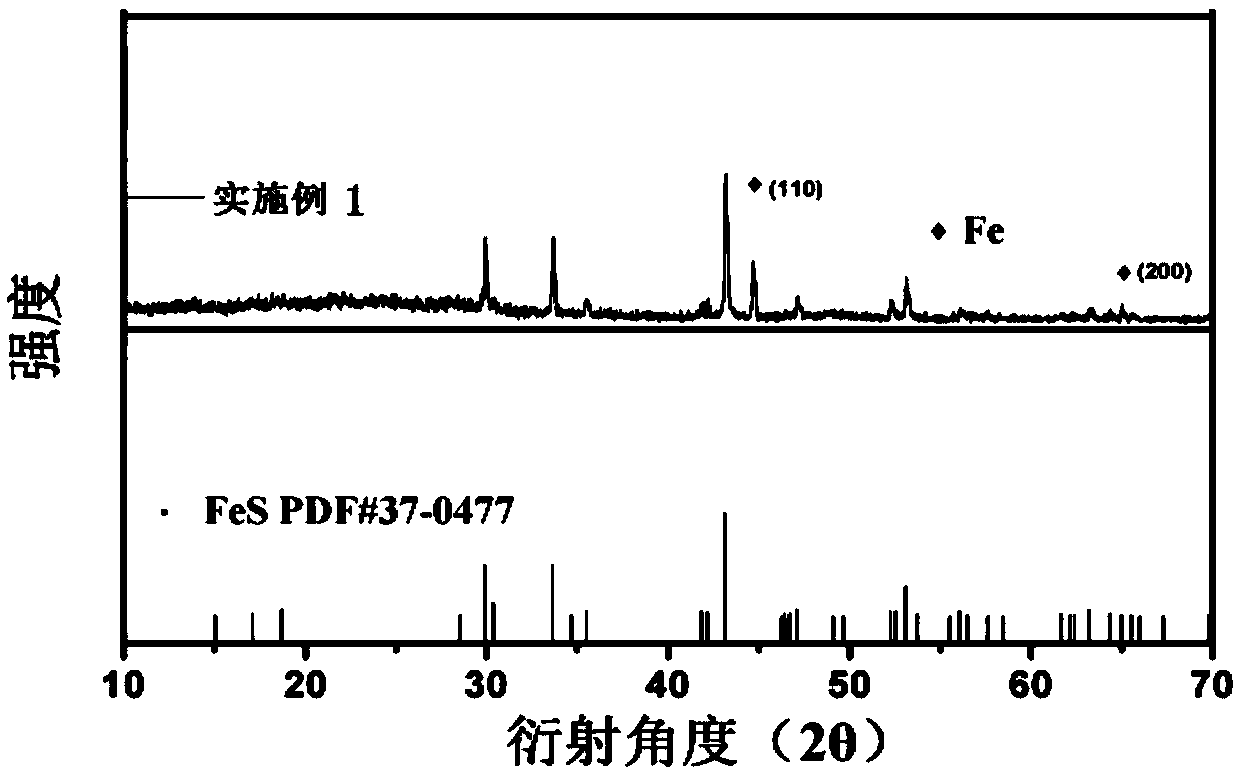

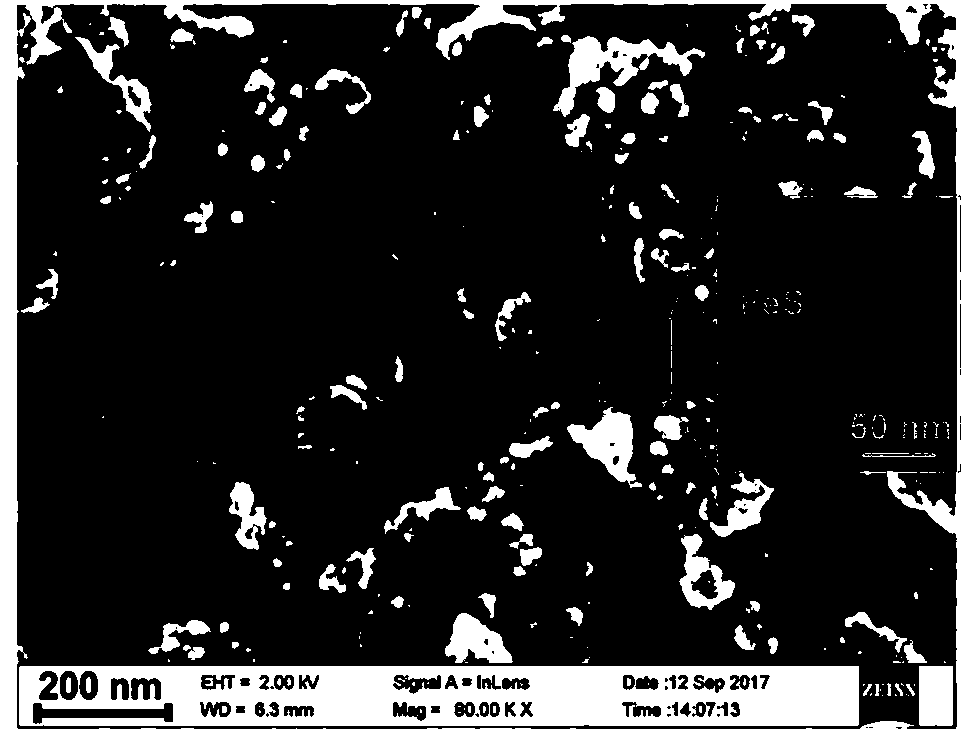

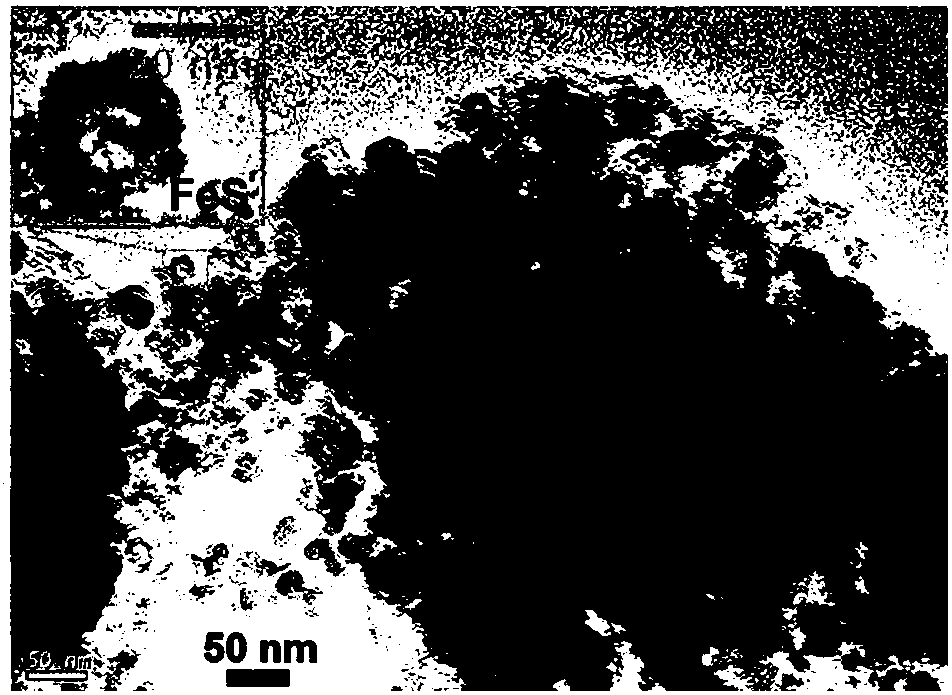

Embodiment 1

[0039] A preparation method of lithium ion battery negative electrode material FeS / Fe / C, comprising steps:

[0040] Dissolve 2.8083g of ferrous sulfate heptahydrate and 2.4509g of sodium sulfide nonahydrate in 50ml of distilled water respectively, and configure 0.2mol L -1 Iron source aqueous solution and 0.2mol L -1 sulfur source aqueous solution; in 50ml iron source aqueous solution, dropwise add 40ml papermaking waste liquid, stir 30min, obtain solution A; in solution A, add dropwise 50ml sulfur source aqueous solution and add 2ml 2wt℅ citric acid aqueous solution (0.0002mol), stir 30min , to obtain a mixture; put the mixture into a reaction kettle, treat it at a constant temperature at 180°C for 18h, and then cool it naturally to room temperature, take out the precipitate and wash it 3 to 4 times to obtain a black mixture, dry it in a 60°C thermostat and fully grind it, and put it in Under the protection of nitrogen atmosphere, calcined at 700°C for 8h, and cooled natural...

Embodiment 2

[0047] A preparation method of lithium ion battery negative electrode material FeS / Fe / C, comprising steps:

[0048] Dissolve 4.1015g of ferric nitrate nonahydrate and 2.5069g of sodium thiosulfate pentahydrate (the sulfur in sodium sulfate in sodium thiosulfate pentahydrate does not participate in the reaction and is not used as a sulfur source) in 50ml of distilled water, and configure 0.2mol L -1 Iron source aqueous solution and 0.2mol L -1 30ml of papermaking waste liquid was added dropwise to 50ml of iron source aqueous solution, and stirred for 30min to obtain solution A; 50ml of sulfur source aqueous solution was added dropwise to solution A and 2ml of 2wt℅citric acid aqueous solution was added, and stirred for 30min to obtain a mixture; Put the mixture into the reaction kettle, treat it at 150°C for 36 hours, then cool it down to room temperature naturally, take out the precipitate and wash it 3 to 4 times to obtain a black mixture, dry it in a constant temperature oven...

Embodiment 3

[0051] A preparation method of lithium ion battery negative electrode material FeS / Fe / C, comprising steps:

[0052] Dissolve 2.7303g of ferric chloride hexahydrate and 0.7689g of thiourea in 50ml of distilled water respectively, and configure 0.2mol L -1 Iron source aqueous solution and 0.2mol L -1 Add 50ml of papermaking waste liquid dropwise to 50ml of iron source aqueous solution, and stir for 30min to obtain solution A; add dropwise 50ml of sulfur source aqueous solution and 2ml of 2wt℅citric acid aqueous solution to solution A, and stir for 30min to obtain a mixture; Put the mixture into a reaction kettle, heat it at 200°C for 10 hours, then cool it down to room temperature naturally, take out the precipitate and wash it 3 to 4 times to obtain a black mixture, dry it in a constant temperature oven at 60°C and fully grind it, then put it under the protection of nitrogen atmosphere , calcined at 800°C for 6h, and naturally cooled to room temperature, the negative electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com