Silicon-carbon composite material and preparation method thereof

A silicon-carbon composite material, a technology for the preparation process, applied in nanotechnology, electrical components, electrochemical generators, etc. for materials and surface science, to achieve the effect of enhancing interaction, improving electrical conductivity, and improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Disperse 0.15 g of silicon nanospheres with a particle size of less than 100 nm in 30 ml of absolute ethanol, add polyvinylpyrrolidone dispersant with a mass of 10% of the silicon nanospheres to aid in dispersion, and ultrasonicate at 50 Hz for 10 minutes;

[0050] (2) Dissolve 0.75g of graphite in 10ml of absolute ethanol, and ultrasonicate at 50Hz for 10min;

[0051] (3) Dissolve 1.5g of carbon quantum dots in 10ml of absolute ethanol, and ultrasonicate at 50Hz for 10min;

[0052] (4) Add the dispersed nanospheres and graphite into the solution containing carbon quantum dots, and mix evenly with 50Hz ultrasonic wave for 10min, then move to a water bath at 80°C, and evaporate the anhydrous ethanol while stirring to obtain the solid content After 90%-97% slurry, vacuum dry at 80°C for 12h;

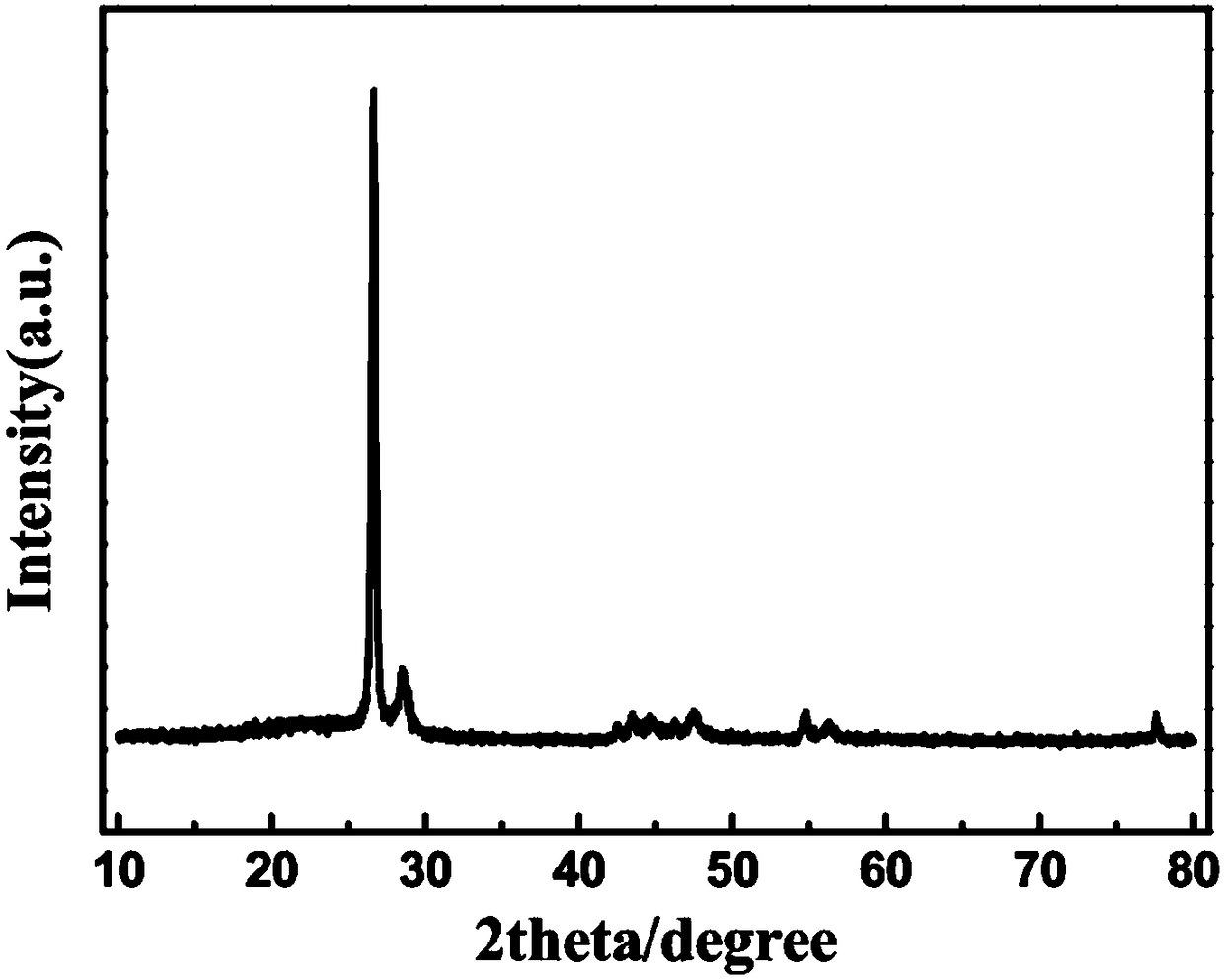

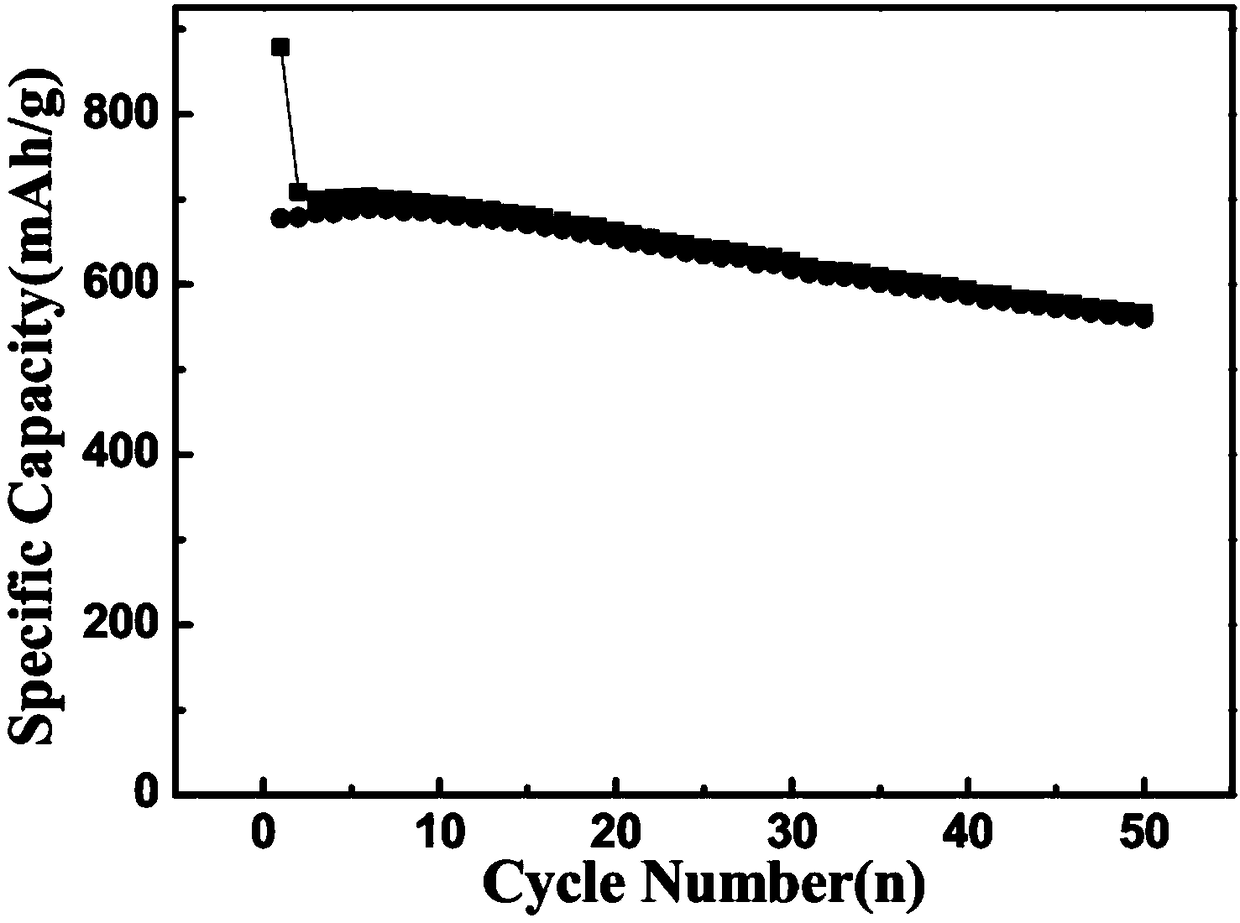

[0053] (5) After the above-mentioned dried material is ground, heated to 600° C. for 3 hours at a rate of 5° C. min under an Ar gas atmosphere to obtain a silicon-carbon compos...

Embodiment 2

[0056] (1) Disperse 0.25 g of silicon nanospheres with a particle size of less than 100 nm in 30 ml of absolute ethanol, add polyvinylpyrrolidone dispersant with a mass of 10% of the silicon nanospheres to aid in dispersion, and ultrasonicate at 50 Hz for 10 minutes;

[0057] (2), 1.5g of citric acid was dissolved in 10ml of absolute ethanol, 50Hz ultrasonic 10min;

[0058] (3) Dissolve 1.5g of carbon quantum dots in 10ml of absolute ethanol, and ultrasonicate at 50Hz for 10min;

[0059] (4) Add the dispersed nanospheres and citric acid into the solution containing carbon quantum dots, and after mixing evenly with 50 Hz ultrasound for 10 min, move it to a water bath at 80 ° C, and evaporate the absolute ethanol therein under stirring to obtain a solid After the slurry with a content of 90%-97%, vacuum dry at 80°C for 10h;

[0060] (5) After grinding the above-mentioned dried materials, heat them to 600° C. for 3 hours at a rate of 5° C. min- under an Ar gas atmosphere to obta...

Embodiment 3

[0063] (1) Disperse 0.15 g of silicon nanospheres with a particle size of less than 100 nm in 30 ml of absolute ethanol, add polyvinylpyrrolidone dispersant with a mass of 10% of the silicon nanospheres to aid in dispersion, and ultrasonicate at 50 Hz for 10 minutes;

[0064] (2), 1.2g of glucose was dissolved in 10ml of absolute ethanol, 50Hz ultrasonic 10min;

[0065] (3) Dissolve 2.0g of carbon quantum dots in 10ml of absolute ethanol, and ultrasonicate at 50Hz for 10min;

[0066] (4) Add the dispersed nanospheres and glucose into the solution containing carbon quantum dots, and after mixing evenly with 50 Hz ultrasound for 10 minutes, move it to a water bath at 80 ° C, evaporate the absolute ethanol in it, and obtain a solution with a solid content of 90 After %-97% slurry, vacuum dry at 80°C for 14h;

[0067] (5) After the above-mentioned dried materials are ground, they are heated at 5°C min under an Ar atmosphere. -1 Heating at a rate of 800°C for 3 hours to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com