Silicon-carbon material serving as lithium ion battery anode and preparation method thereof

A technology of lithium-ion batteries and silicon-carbon materials, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problems of accelerated capacity decay, attenuation, and inability to produce surface solid electrolyte membranes, etc. To achieve the effect of buffering volume expansion and enriching the pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

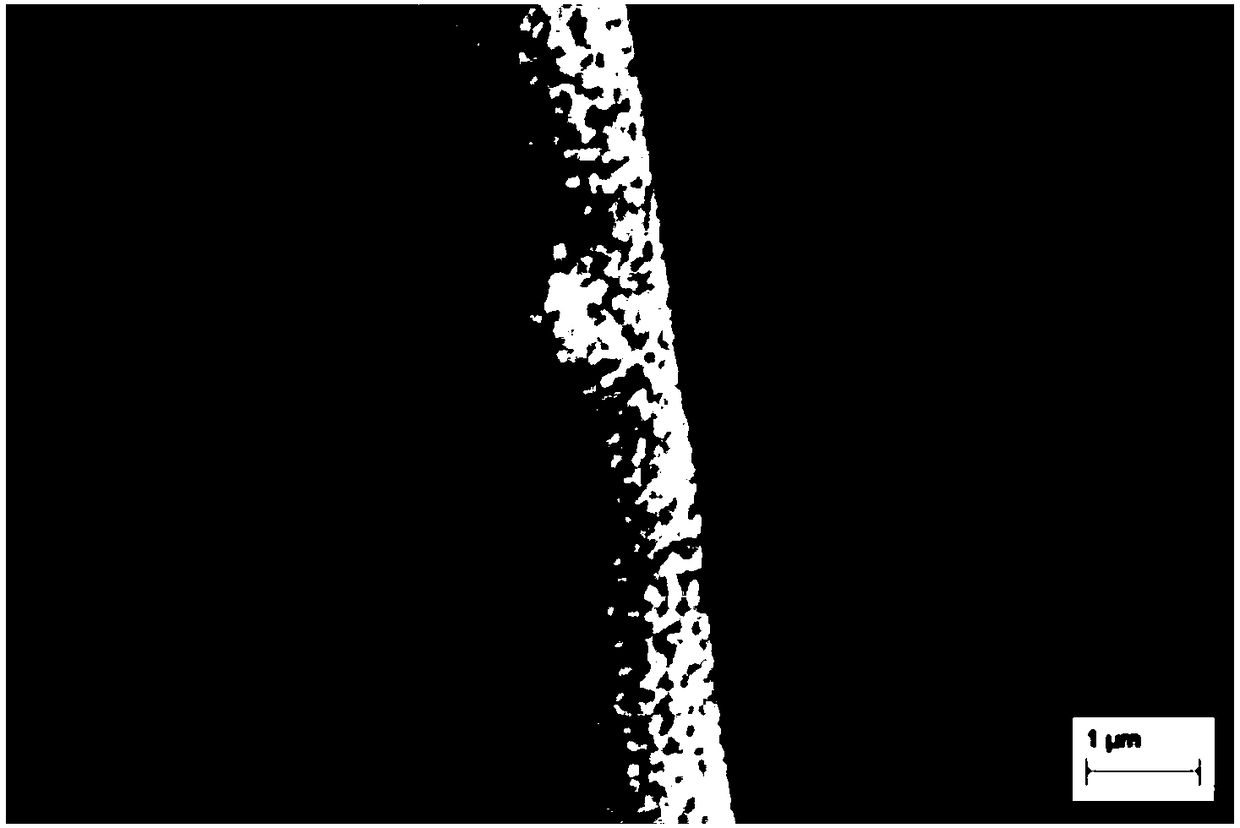

Image

Examples

Embodiment 1

[0023] A method for preparing a new-structured silicon-carbon material for the negative electrode of a lithium ion battery, the specific steps are as follows:

[0024] (1) Preparation of porous silicon:

[0025] Polycrystalline silicon powder cleaning: Soak 350 mesh 5g silicon powder with a 9% HCl solution for 25 minutes to remove impurities; filter with a 100 mesh porous filter membrane and clean it with deionized water for later use;

[0026] Deposition of nano-Ag particles: Put the cleaned polysilicon powder into a mixed solution of 0.01mol / L AgNO3 and 1% HF, deposit Ag for 1 min, and coat the surface of silicon with nano-particle Ag; use 100 Purpose the porous filter membrane is filtered and cleaned with deionized water for use;

[0027] The appearance of porous silicon: the silicon powder deposited with Ag particles is placed in 5% HF and 1% H 2 O 2 In the mixed etching solution, at 20℃, react for 2h, Ag is used as a catalyst to accelerate the reaction of silicon around Ag partic...

Embodiment 2

[0034] A method for preparing a new-structured silicon-carbon material for the negative electrode of a lithium ion battery, the specific steps are as follows:

[0035] (1) Preparation of porous silicon:

[0036] Polycrystalline silicon powder cleaning: soak 8g of 400 mesh silicon powder for 30 minutes with a mass fraction of 10% HCl solution, the purpose is to remove impurities; filter with a 200 mesh porous membrane, and clean it with deionized water for later use;

[0037] Deposition of nano-Ag particles: Put the cleaned polysilicon powder into a mixed solution of 0.02mol / L AgNO3 and 2% HF, deposit Ag for 2min, and coat the surface of silicon with nano-particle Ag; use 200 Purpose the porous filter membrane is filtered and cleaned with deionized water for use;

[0038] The appearance of porous silicon: the silicon powder deposited with Ag particles is placed in 8% HF and 1% H 2 O 2 In the mixed etching solution, at 20℃, react for 2h. Ag is used as a catalyst to accelerate the reacti...

Embodiment 3

[0045] A method for preparing a new-structured silicon-carbon material for the negative electrode of a lithium ion battery, the specific steps are as follows:

[0046] (1) Preparation of porous silicon:

[0047] Polycrystalline silicon powder cleaning: Soak 10g silicon powder of 450 mesh with a mass fraction of 11% HCl solution for 35 minutes, the purpose is to remove impurities; filter with a 300 mesh porous filter membrane, and rinse with deionized water for use;

[0048] Deposit nano Ag particles: Put the cleaned polysilicon powder into 0.03mol / L AgNO 3 In the mixed solution of 3% HF and 3% HF, deposit Ag for 3 minutes, and plate the surface of the silicon with nano-particle Ag; filter with a 300 mesh porous filter membrane, and clean it with deionized water for use;

[0049] The appearance of porous silicon: the silicon powder deposited with Ag particles is placed in HF with a mass fraction of 10% and a mass fraction of 1.5% H 2 O 2 In the mixed etching solution, at 30℃, react for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com