Gel electrolyte capable of improving cathode/electrolyte interface stability and preparation method thereof

A gel electrolyte and electrolyte technology, which is applied in the field of lithium-ion batteries, can solve the problems that high liquid absorption rate and structural stability cannot be balanced, and the work has not yet been explored, so as to improve interface compatibility, increase liquid absorption rate, and stabilize The effect of the interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

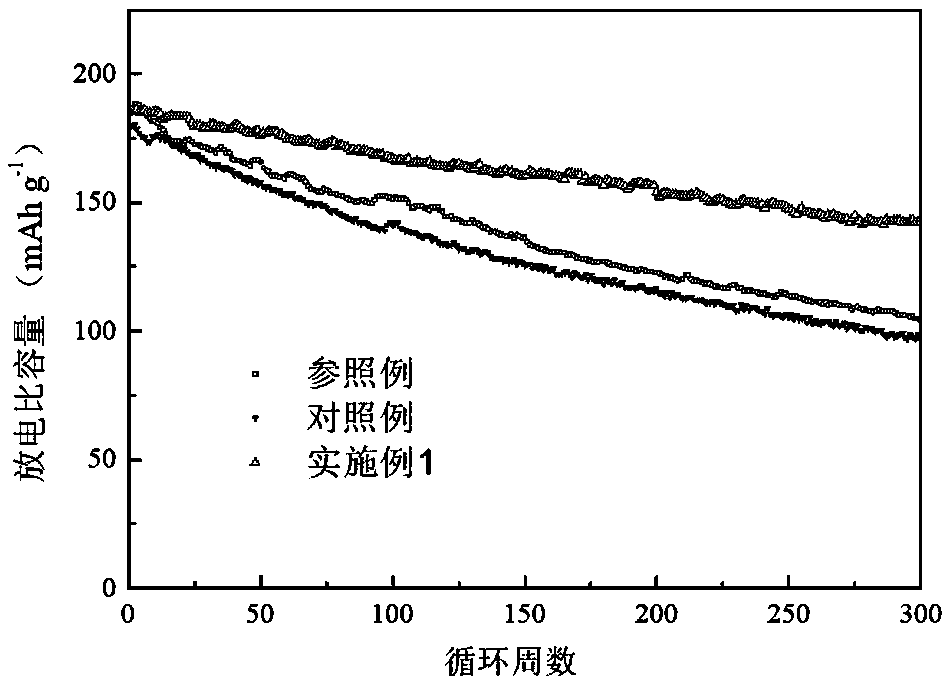

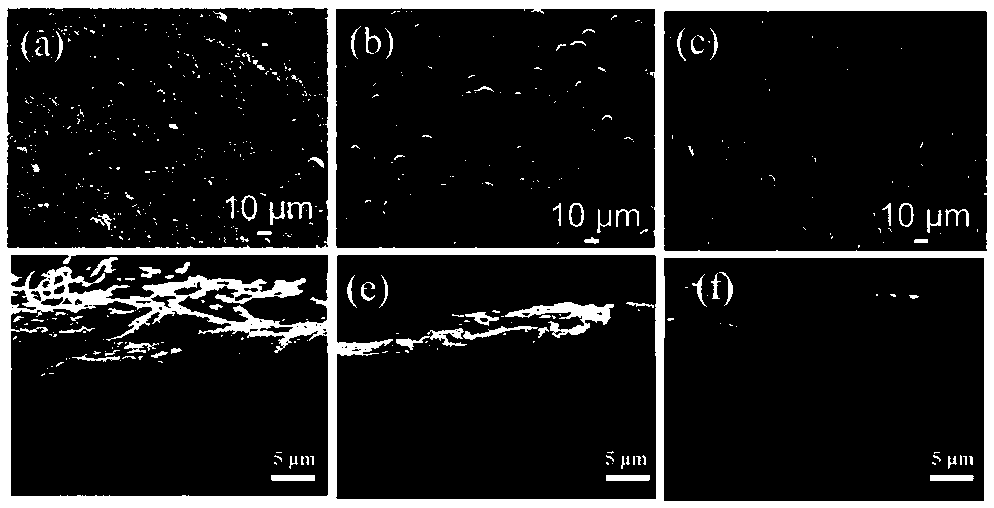

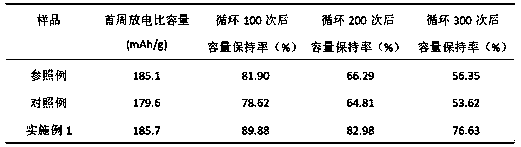

Examples

preparation example Construction

[0025] A typical embodiment of the present invention provides a method for preparing a gel electrolyte that improves the stability of the positive electrode / electrolyte interface, including:

[0026] Step (1), preparation of the polymer membrane: the electrolyte matrix material with a mass ratio of 3:7−9:1 and cellulose acetate (CA) were stirred and dissolved in an organic solvent at 40−90°C, and after 4−12 hours A uniform slurry is obtained, and the slurry is made into a polymer film by electrospinning;

[0027] Step (2), sodium alginate (SA) modified polymer membrane: the polymer membrane prepared in step (1) was infiltrated with a mixed solvent of ethanol and water with a volume ratio of 1:9−6:4, and then dissolved in alginic acid After soaking in sodium aqueous solution for 6-24 hours, take it out, and dry it at 50-80°C to obtain the SA-modified polymer film;

[0028] Step (3), preparation of gel electrolyte: soak the SA-modified polymer membrane prepared in step (2) in l...

Embodiment 1

[0040] (1) Dissolve 1.05g of polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) with a mass ratio of 7:3 and 0.45g of cellulose acetate (hydroxyl content 4.0wt.%) in 10mL of a volume ratio of 3:7 In a mixed solvent of acetone and N,N-dimethylacetamide (DMAc), heat and stir at 45°C for 6h until dissolved to obtain a homogeneous slurry. The above slurry was prepared into a polymer film by electrospinning (spinning conditions: advancing speed 1mL / h, electrostatic field voltage 20KV, receiving distance 15cm).

[0041] (2) Soak the polymer film prepared in the above steps with a mixed solvent of ethanol and water with a volume ratio of 3:7 for 2 minutes, take it out, soak it in 0.5wt.% sodium alginate aqueous solution for 10 hours, take it out, 60°C Dry to obtain a sodium alginate modified polymer film.

[0042] (3) In a glove box filled with argon, place the SA-modified polymer film prepared in step (2) in a liquid electrolyte, the composition of which is 1mol / L LiPF 6 Disso...

Embodiment 2

[0055] The difference from the preparation process of Example 1 is that step (1) is changed to: 1.2 g of polyvinylidene fluoride-hexafluoropropylene (PVDF−HFP) with a mass ratio of 8:2 and cellulose acetate (hydroxyl content 4.0 wt.%) 0.3g was dissolved in 10mL of acetone and N,N-dimethylacetamide (DMAc) mixed solvent with a volume ratio of 3:7, heated and stirred at 45°C for 6h until dissolved. The above slurry was prepared into a film by electrospinning (spinning conditions: advancing speed 1mL / h, electrostatic field voltage 20KV, receiving distance 18cm).

[0056] Other steps are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com