TiO2/CNTs/PES composite forward osmosis membrane, preparation method and application thereof

A technology of forward osmosis membrane and base membrane, applied in the field of TiO2/CNTs/PES composite forward osmosis membrane and its preparation, can solve the potential hazards of aquatic animals, plants and human health, the spread of drug-resistant bacteria and resistant genes, and the difficulty of degrading antibiotics and other problems, to achieve the effect of high mechanical properties, strong permeability, and strong hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

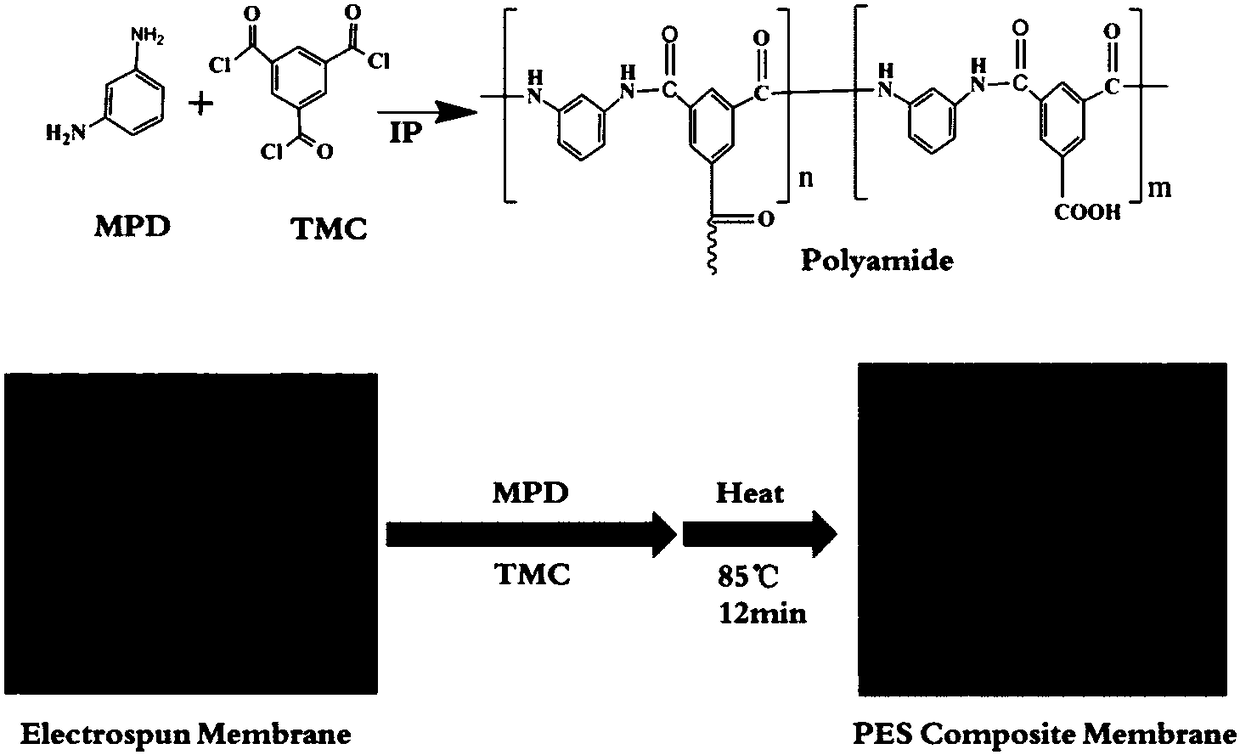

Method used

Image

Examples

Embodiment 1

[0031] (1) Weigh 0.0715gTiO respectively 2 and 0.0307g of CNTs were dispersed in 12mL of DMF solvent, ultrasonicated for 30min, then 3.9822g of PES was added, placed on a magnetic stirrer with the temperature set at 65°C and stirred for 5-6h to obtain 26wt% PES, 0.45wt% TiO 2 , 0.2wt% CNTs uniform spinning solution, and then the spinning solution was left standing for degassing for 2 hours to obtain TiO 2 / CNTs / PES spinning solution.

[0032] (2) Wind the PET non-woven fabric and stick it on the receiving roller; slowly pour the spinning solution prepared in step (1) into a 10mL syringe, the syringe needle adopts a flat needle with an inner diameter of 0.7mm, and then place the syringe Connect the high-voltage power supply to the controller; carry out electrospinning, and the spinning parameters are set as follows: the spinning voltage is 20kV, the spinning liquid propulsion speed is 1mL / h, the receiving roller speed is 300r / min, the spinneret and the receiving roller are Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com