Method for converting cellulose into bioethanol by one-pot method

A bioethanol and cellulose technology, applied in chemical instruments and methods, preparation of organic compounds, chemical/physical processes, etc., can solve the problems of cumbersome, difficult to operate, complex purification and separation processes, etc., to achieve simple process and reduce raw materials. Cost, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

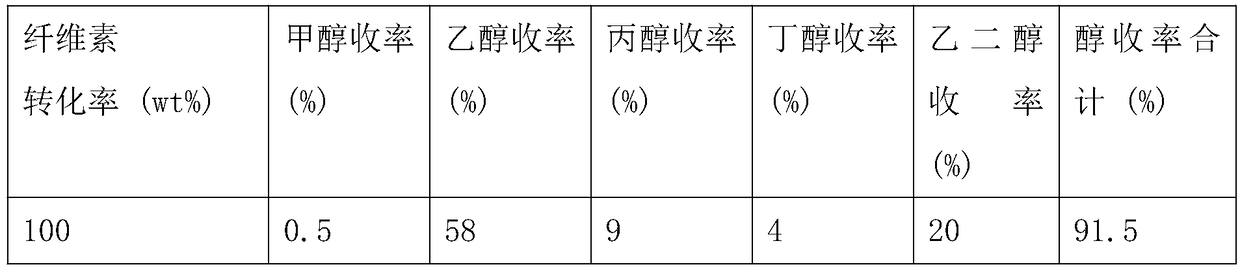

Embodiment 1

[0029] (1) A Cu-based catalyst was synthesized by a two-step method, and the Cu-based catalyst was Pt-Co-Cu / SiO 2 ; The specific method is:

[0030] Step 1.1, weigh 1.2g copper nitrate hexahydrate (Cu(NO 3 ) 2 .3H 2 O), 0.2g cobalt nitrate hexahydrate (Co(NO 3 ) 2 .3H 2 O) being dissolved in 200ml concentration is in the urea solution of 1mol / L; Then add 1g nanometer SiO 2 , after hydrothermal reaction for 3 hours, calcined at 450°C for 2 hours to obtain the calcined product.

[0031] Step 1.2, put the calcined product in a small beaker, add 1ml of H with a concentration of 0.01g / ml 2 PtCl 6 solution. After stirring until dry, place in a 90°C oven for 12 hours.

[0032] Step 1.3, take out the product from the oven, put it into a tubular calciner, reduce it in a hydrogen atmosphere at a temperature of 450°C for 3 hours, cool it to room temperature and age it with nitrogen containing 5% air for 12 hours to obtain the catalyst Pt-Co-Cu / SiO 2 .

[0033] (2) Preparati...

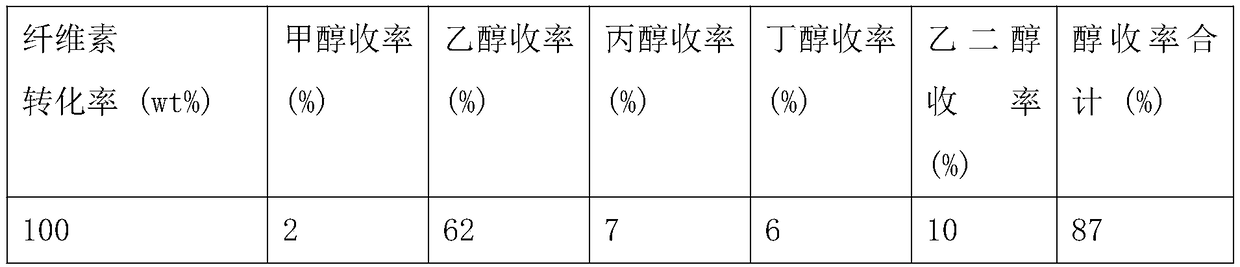

Embodiment 2

[0041] (1) Synthesis of W-based catalyst by impregnation method, W-based catalyst is WO 3 / C, the specific method is as follows:

[0042]Step 1.1, weigh 0.5g of ammonium tungstate into a small beaker, add 1g of activated carbon powder, stir until dry, then dry in an oven at 80°C.

[0043] Step 1.2, put the dried mixture of ammonium tungstate and activated carbon powder into a tubular calciner at 500°C, calcinate in a nitrogen atmosphere for 2 hours, and then reduce in a hydrogen atmosphere for 2 hours.

[0044] Step 1.3, after the calcined mixture drops to room temperature, it is aged for 12 hours with nitrogen containing 5% air, and the catalyst obtained is WO 3 / C.

[0045] (2) A Cu-based catalyst was synthesized by a two-step method, and the Cu-based catalyst was Ru-Co-Cu / SiO 2 , the specific method is:

[0046] Step 2.1, weigh 1.2g copper nitrate hexahydrate (Cu(NO 3 ) 2 .3H 2 O), 0.2g cobalt nitrate hexahydrate (Co(NO 3 ) 2 .3H 2 O) be dissolved in 200ml concent...

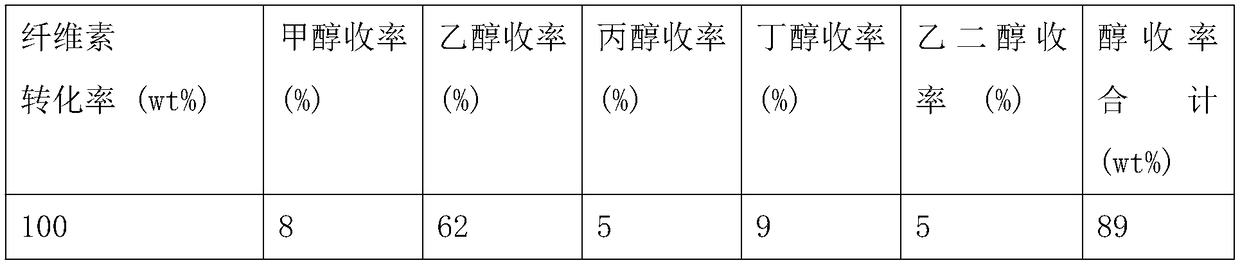

Embodiment 3

[0057] (1) Synthesis of W-based catalyst by impregnation method, W-based catalyst is W 2 C / mesoporous carbon, the specific method is:

[0058] Step 1.1, weigh 0.5g of ammonium tungstate and put it into a beaker, add 1g of mesoporous carbon, stir until dry, then dry in an oven at 80°C to obtain a mixture of ammonium tungstate and mesoporous carbon after drying.

[0059] Step 1.2, put the dried mixture of ammonium tungstate and mesoporous carbon into a 500°C tubular calciner, calcinate for 2 hours in a nitrogen atmosphere, and then reduce it for 1 hour at a temperature of 800°C in a hydrogen atmosphere to obtain a reduced product .

[0060] Step 1.3, after the reduced product has dropped to room temperature, it is aged with nitrogen containing 5% air for 12 hours to obtain the catalyst W 2 C / mesoporous carbon.

[0061] (2) A Cu-based catalyst was synthesized by a two-step method, and the Cu-based catalyst was Pd-Co-Cu / SiO 2 , the specific method is:

[0062] Step 2.1, weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com