Nano-fiber thin-membrane filter material preparation method and product thereof

A nanofiber and membrane filtration technology, which is applied in separation methods, filtration separation, and dispersed particle filtration, etc., can solve the problems of poor filtration effect and achieve small diameter, good hydrophobicity and moisture resistance, and enhanced piezoelectric performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

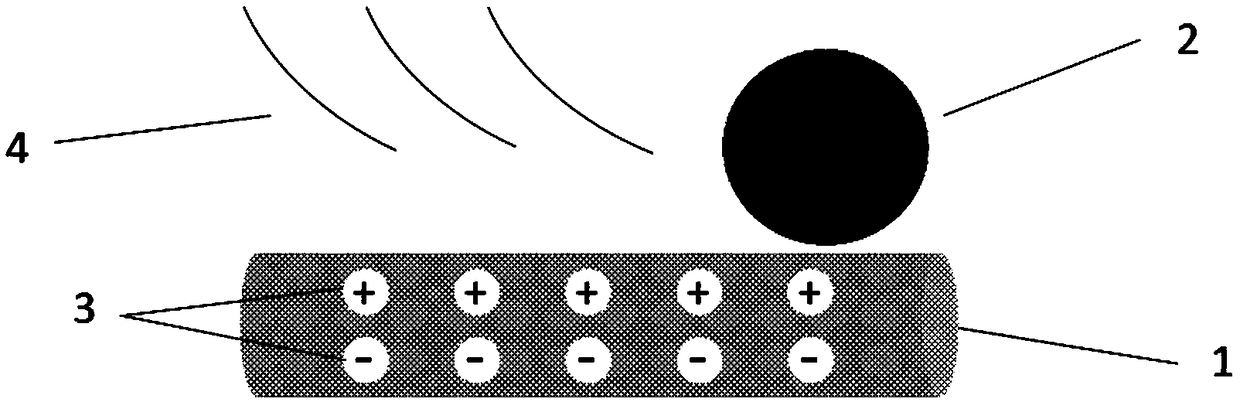

[0031] The preparation method of the nanofiber membrane filter material provided by the present invention specifically comprises the following steps:

[0032] (1) Mix organic piezoelectric material or organic electrostatic adsorption material as parent material with inorganic piezoelectric material or electrostatic adsorption nanomaterial and solvent, and stir the organic piezoelectric material or organic electrostatic adsorption material at a preset temperature for a set period of time to dissolve the organic piezoelectric material or organic electrostatic adsorption material , Inorganic piezoelectric materials or electrostatic adsorption nanomaterials are uniformly dispersed to obtain a spinning solution with viscosity;

[0033] (2) spinning the obtained spinning solution by an electrospinning method, and receiving electrospinning nanofibers on the substrate to form a nanofiber film;

[0034](3) Annealing, polarization, cutting, and repolarization are performed on the nanofi...

Embodiment 1

[0044] (1) Mix 3.0g of polyvinylidene fluoride-hexafluoropropylene copolymer as a matrix material and 1g of barium titanate nanoparticles with 7.2g of acetone and 3.6g of N,N dimethylformamide, and stir at 55 degrees Celsius 3 hours, obtain spinning solution;

[0045] (2) The obtained spinning solution is added into the syringe, and the needle is connected to a high-voltage power supply, the spinning voltage is set to 25kV, the spinning distance is 10 cm, and the flow rate of the spinning solution is 1.5mL / h; the obtained diameter is Electrospinning nanofibers of 600 nanometers are received by metal rollers, and electrospinning nanofiber films are obtained after spinning for 1.5 hours;

[0046] (3) Annealing, polarization, cutting, and repolarization are performed on the obtained electrospun nanofiber film to obtain a nanofiber film filter material for high flow rate scenarios.

Embodiment 2

[0048] (1) Mix 3.0g of polyvinylidene fluoride-hexafluoropropylene copolymer as a matrix material and 0.2g of zinc oxide nanoparticles with 7.2g of acetone and 3.6g of N,N dimethylformamide, and stir at 55 degrees Celsius 3 hours, obtain spinning solution;

[0049] (2) The above-mentioned spinning solution is added in the syringe, and the needle is connected to a high-voltage power supply, the spinning voltage is set to 20kV, the spinning distance is 13 cm, and the flow rate of the spinning solution is 2mL / h; the obtained diameter is 750 Nano electrospun nanofibers are received by metal rollers, and electrospun nanofiber films are obtained after spinning for 1 hour;

[0050] (3) Annealing, polarization, cutting, and repolarization are performed on the obtained electrospun nanofiber film to obtain a nanofiber film filter material for high flow rate scenarios.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com