Pretreatment agent and pretreatment method for oil-gas-workplace-station organic waste gas

A technology of organic waste gas and pretreatment agent, which is applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc. It can solve the problems of increasing the cost of catalytic oxidation treatment, reducing the active components of catalysts, and expensive precious metals, etc., so as to improve the processability and processing efficiency, equipment maintenance cycle extension, and the effect of replacement cycle extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The pretreatment of organic waste gas in oil and gas operation stations is carried out in accordance with the following steps:

[0024] (1) Add diethylene glycol, diglycolamine, and glycerin that are miscible in any ratio to the container to prepare a base liquid. The base liquid has a buffer function and can keep the pH value stable between 8 and 9. The ratio of the three: Diethylene glycol amine 50% to 55%, diethylene glycol 20% to 25%; glycerol (glycerol) 20% to 25%.

[0025] (2) Add sodium citrate in the base liquid, the dosage is 0.5% to 1.0%, stir slowly for 5 minutes and let it stand still, cover and seal the container, open the positive pressure breathing valve of the sealing cover, and set aside.

[0026] (3) Connect the dissolved air pump and the air tank with the container containing the pretreatment agent, turn on the dissolved air pump, blow air into the dissolved air pump and pressurize it, so that the dissolved air ratio is within the range of 2.0 to 3.0:...

Embodiment 2

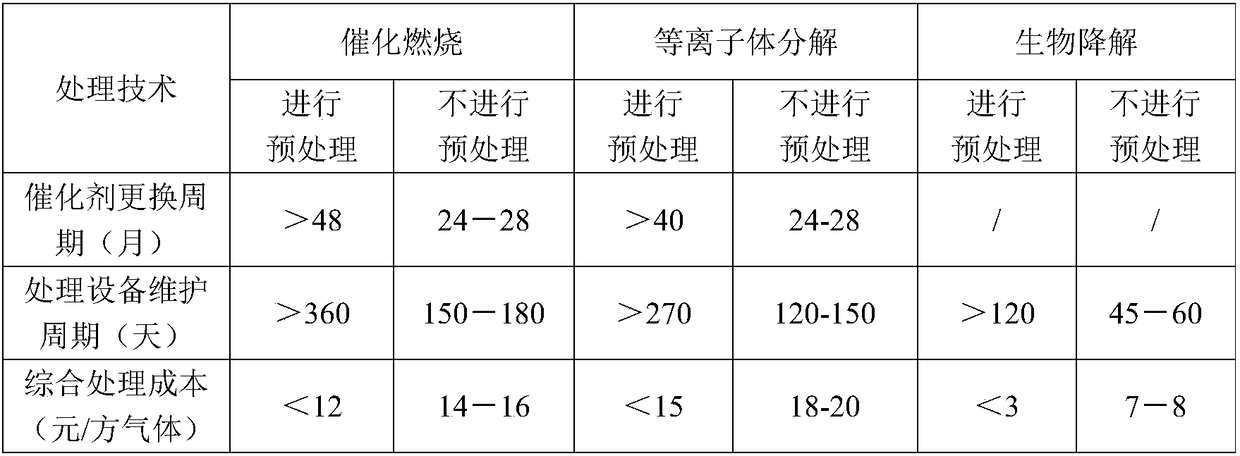

[0031] Since 2012, a treatment test has been carried out by the method described in Example 1, and a total of 4 tests have been carried out for the organic waste gas discharged unorganized from Changqing Oilfield operation stations (transfer stations, booster stations, gathering stations, and combined stations). , respectively tested the experimental evaluation of catalytic combustion, low-temperature plasma decomposition, biological treatment and other treatment technologies, designed a comparative experiment, and evaluated the experimental results as follows:

[0032]

[0033] Compared with the catalytic combustion process without pretreatment, in the catalytic combustion process with pretreatment, the catalyst replacement cycle is extended by more than 70%, the equipment maintenance cycle is more than doubled, and the comprehensive treatment cost is reduced by more than 20%;

[0034] Compared with the plasma decomposition technology without pretreatment, in the plasma dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com