Preparation method of flame-retardant and anti-corrosive metallic paint with high adhesion

A metal coating and adhesion technology, used in anti-corrosion coatings, fire-retardant coatings, coatings, etc., can solve problems such as poor corrosion resistance, poor adhesion, and flammability, and achieve the effect of preventing corrosion, improving adhesion, and preventing corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

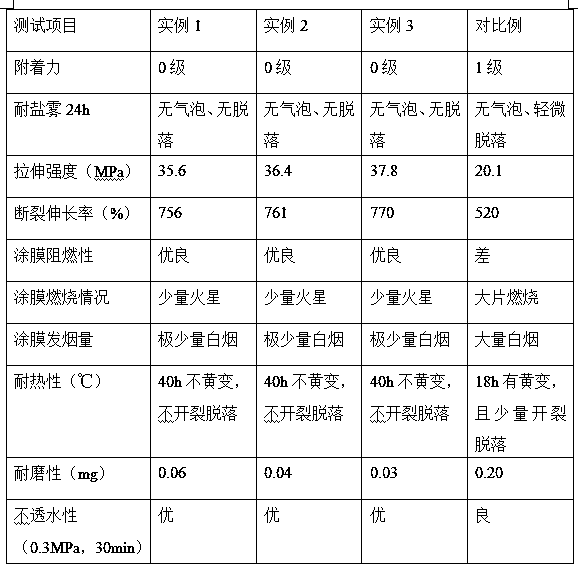

Examples

Embodiment Construction

[0026] Put phenyl dichlorophosphate and tetrahydrofuran into the reactor at a mass ratio of 1:3, cool down the reactor to 0-3°C, and stir for 10-20 minutes under the protection of nitrogen to obtain a mixed solution, then add the mixed solution into the reactor Triethylamine with a liquid quality of 20-25%, continue to stir for 15-20min to obtain a reaction solution; dropwise add boric acid diglyceride with a reaction solution quality of 15-18% to the above-mentioned reaction solution, and heat up to 30-40 ℃, stirred at a speed of 100-120r / min for 4-5h, then filtered while hot to obtain the filtrate, put the filtrate in a vacuum drying oven, and dried for 3-5h at 40-45°C and a vacuum of 0.6-0.8MPa , to obtain a viscous polymer; the above viscous polymer and epoxy resin are mixed and put into the reactor at a mass ratio of 1:3, and the reaction is stirred under the condition that the vacuum degree is 0.08-0.12MPa and the temperature is 58-62°C After 40-60 minutes, the phosphoru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com