Sulfonated polybenzimidazole proton exchange membrane, preparation method and application

A technology of sulfonated polybenzimidazole and proton exchange membrane, which is applied in electrochemical generators, fuel cells, electrical components, etc., can solve the problems of low acid doping, low battery voltage efficiency, and reduced proton conductivity. Achieve the effects of simple synthesis operation, good thermal stability and mechanical properties, and increase conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

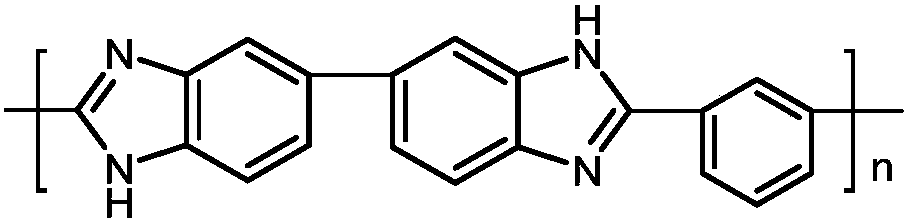

[0034] (1) 30g polyphosphoric acid (PPA) is added in the there-necked flask of 100ml, add 5mmol biphenyltetramine, 2.5mmol 5-sodium sulfonate-isophthalic acid, 2.5mmol isophthalic acid, and the monomer concentration is 7wt%, nitrogen was introduced, the air in the three-necked flask was removed, the temperature was raised to 180°C, the reaction was performed for 6h, the stirring was stopped, poured into a 2wt% sodium hydroxide solution while hot, and washed with water until the solution became neutral. Filter and dry.

[0035] (2) The prepared polymer was dissolved in NMP solvent at 100° C. to form a solution with a concentration of 3 wt %, the solution was cast on a glass plate, and flattened with a casting knife. After drying at 60 °C for 6 h, then vacuum drying at 80 °C for 6 h, the membrane was removed from the glass plate. A polybenzimidazole ion exchange membrane with a thickness of about 20 μm and a degree of sulfonation of 50% was obtained.

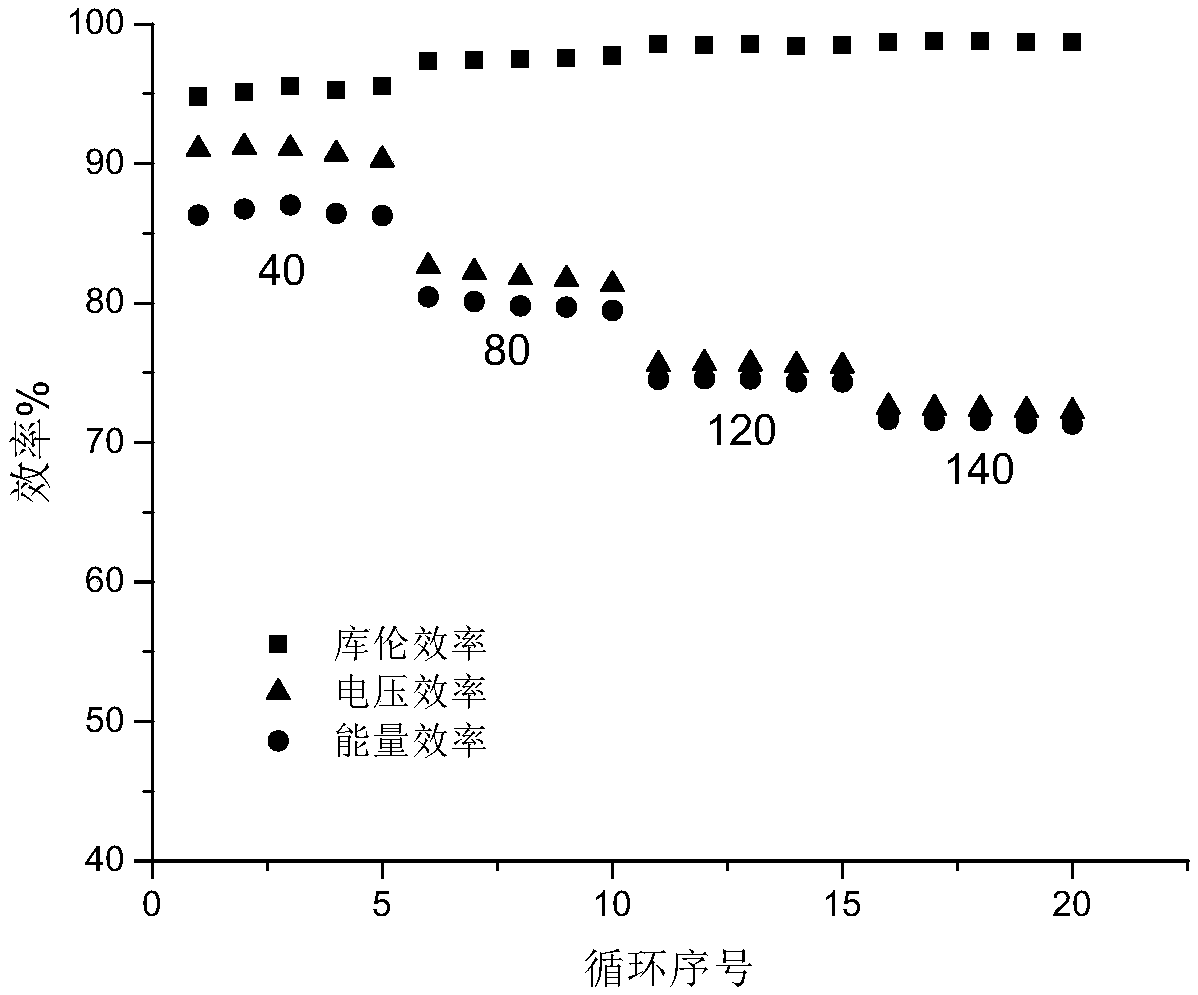

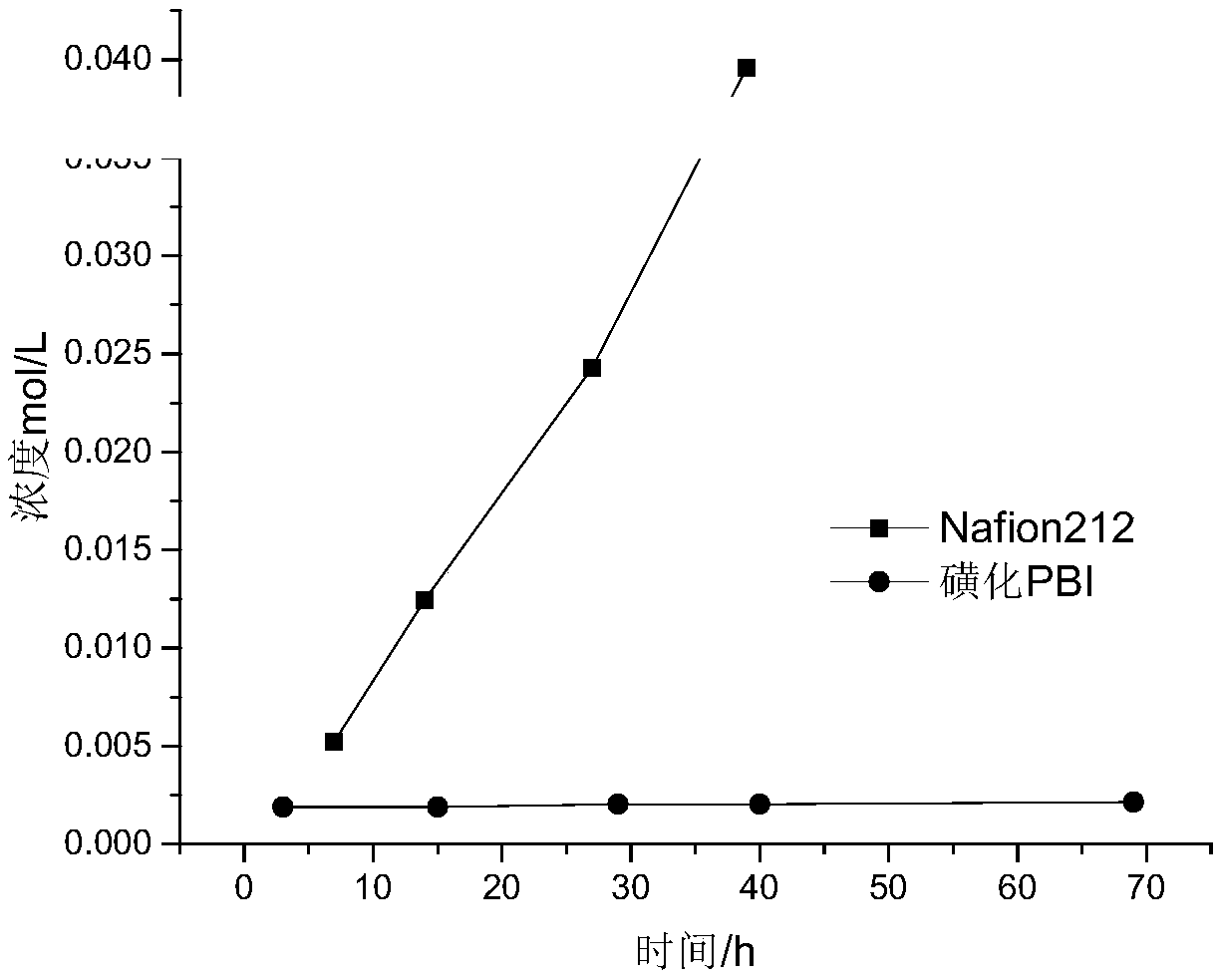

[0036] The application o...

Embodiment 2

[0041] (1) 20g polyphosphoric acid (PPA) is added in the there-necked flask of 100ml, add 5mmol biphenyltetramine, 2mmol 5-sodium sulfonate-isophthalic acid, 3mmol isophthalic acid, and the monomer concentration is 9.5wt% , pass nitrogen, remove the air in the three-necked flask, heat up to 190 ° C, react for 8 hours, stop stirring, pour it into 4wt% sodium hydroxide solution while hot, and wash with water until the solution is neutral. Filter and dry.

[0042] (2) The prepared polymer was dissolved in DMSO solvent at 110° C. to form a solution with a concentration of 4 wt %, the solution was cast on a glass plate, and flattened with a casting knife. After drying at 70 °C for 8 h, then vacuum drying at 90 °C for 8 h, the membrane was removed from the glass plate. A polybenzimidazole ion-exchange membrane with a thickness of about 30 μm and a degree of sulfonation of 40% was obtained.

[0043] The application of the sulfonated polybenzimidazole proton exchange membrane of the...

Embodiment 3

[0048] (1) 20g polyphosphoric acid (PPA) was added in the there-necked flask of 100ml, 5mmol biphenyltetramine, 2.5mmol 3,3'-sodium disulfonate-4,4'-biphenyl dicarboxylic acid, 2.5mmol were added Isophthalic acid, the monomer concentration is 12wt%, pass nitrogen gas, remove the air in the three-necked flask, heat up to 200 ° C, react for 10h, stop stirring, pour it into a 6wt% sodium hydroxide solution while it is still hot, and fully wash with water , until the solution is neutral. Filter and dry.

[0049] (2) Dissolve the prepared polymer in DMSO solvent at 120° C. to form a solution with a concentration of 5 wt %, cast the solution on a glass plate, and flatten it with a film-casting knife. After drying at 80 °C for 8 h, then vacuum drying at 100 °C for 10 h, the membrane was removed from the glass plate. A polybenzimidazole ion exchange membrane with a thickness of about 40 μm and a degree of sulfonation of 50% was obtained.

[0050] The application of the sulfonated p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com