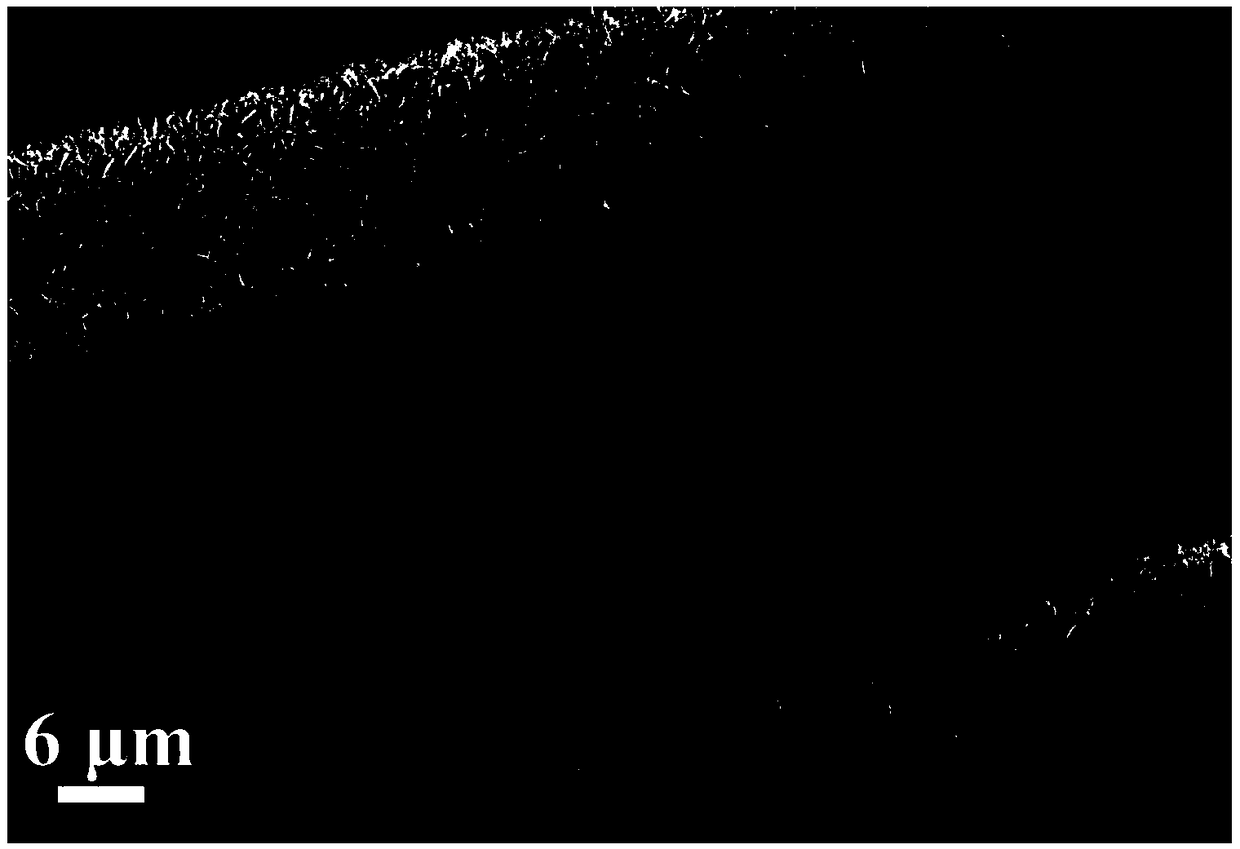

Porous CoAl bimetal hydroxide@carbon fabric composite electrode material and preparation method thereof

A hydroxide and composite electrode technology, applied in the field of material chemistry, can solve problems such as easy agglomeration and poor conductivity of bimetallic oxides, achieve high specific capacitance, overcome poor cycle performance, and have strong mechanical flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing a porous CoAl double metal hydroxide@carbon cloth composite electrode material, comprising the following steps:

[0035] (1) Pretreatment of carbon cloth

[0036] a. Cut the carbon cloth into 2*2cm 2 The shape was washed successively with deionized water, acetone, ethanol, and deionized water for 15 minutes, and then washed twice with deionized water (the mass percent concentration of the acetone is 60-98%, and ethanol is absolute ethanol) ;

[0037] b. Then vacuum dry at 60° C. for 12 hours.

[0038] (2) Preparation of CoAl hydroxide

[0039] a. First, at room temperature, according to the mass ratio, add 150mg of cobalt nitrate and 120mg of aluminum nitrate into a 200ml beaker, and add 80ml of deionized water into it, stir magnetically for 20min until completely mixed;

[0040] b. Then add 150 mg of urea and 40 mg of ammonium fluoride to the above solution, and stir magnetically for 20 minutes until the mixture is evenly mixed to obtain a do...

Embodiment 2

[0050] A method for preparing a porous CoAl double metal hydroxide@carbon cloth composite electrode material, comprising the following steps:

[0051] (1) Pretreatment of carbon cloth

[0052] a. Cut the carbon cloth into 2.5*2.5cm 2 The shape was washed successively with deionized water, acetone, ethanol, and deionized water for 15 minutes, and then washed twice with deionized water (the mass percent concentration of the acetone is 60-98%, and ethanol is absolute ethanol) ;

[0053] b. Then vacuum dry at 60° C. for 12 hours.

[0054] (2) Preparation of CoAl hydroxide

[0055] a. First, at room temperature, according to the mass ratio, add 200mg of cobalt nitrate and 150mg of aluminum nitrate into a 200ml beaker, and add 120ml of deionized water into it, stir magnetically for 20min until completely mixed;

[0056] b. Then add 300 mg of urea and 50 mg of ammonium fluoride to the above solution, and stir magnetically for 20 minutes until the mixture is evenly mixed to obtain...

Embodiment 3

[0065] A method for preparing a porous CoAl double metal hydroxide@carbon cloth composite electrode material, comprising the following steps:

[0066] (1) Pretreatment of carbon cloth

[0067] a. Cut the carbon cloth into 2*2cm 2 The shape was washed successively with deionized water, acetone, ethanol, and deionized water for 15 minutes, and then washed twice with deionized water (the mass percent concentration of the acetone is 60-98%, and ethanol is absolute ethanol) ;

[0068] b. Then vacuum dry at 60° C. for 12 hours.

[0069] (2) Preparation of CoAl hydroxide

[0070] a. First, at room temperature, according to the mass ratio, add 260mg of cobalt nitrate and 160mg of aluminum nitrate into a 200ml beaker, and add 120ml of deionized water into it, stir magnetically for 30min until completely mixed;

[0071] b. Then add 400 mg of urea and 60 mg of ammonium fluoride to the above solution, stir magnetically for 30 minutes until the mixture is uniform, and obtain a double m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com