Selenium-heteroatom doped graphene hollow sphere composite positive electrode material and preparation method thereof

A technology of composite cathode materials and heteroatoms, which is applied in battery electrodes, electrical components, non-aqueous electrolyte batteries, etc., can solve the problems of low energy density and small selenium loading of lithium-selenium batteries, and can suppress the shuttle effect and improve the loading capacity. , the effect of high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

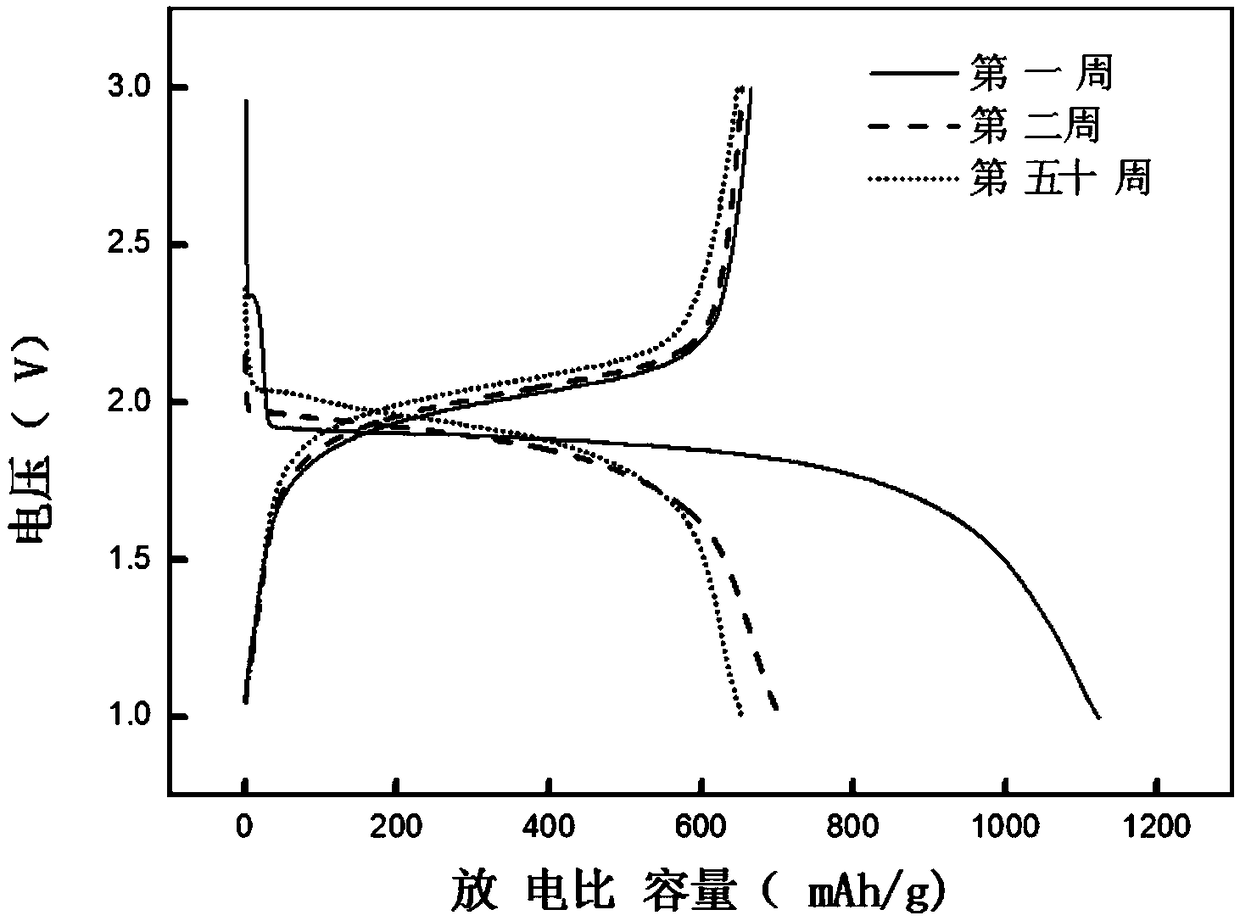

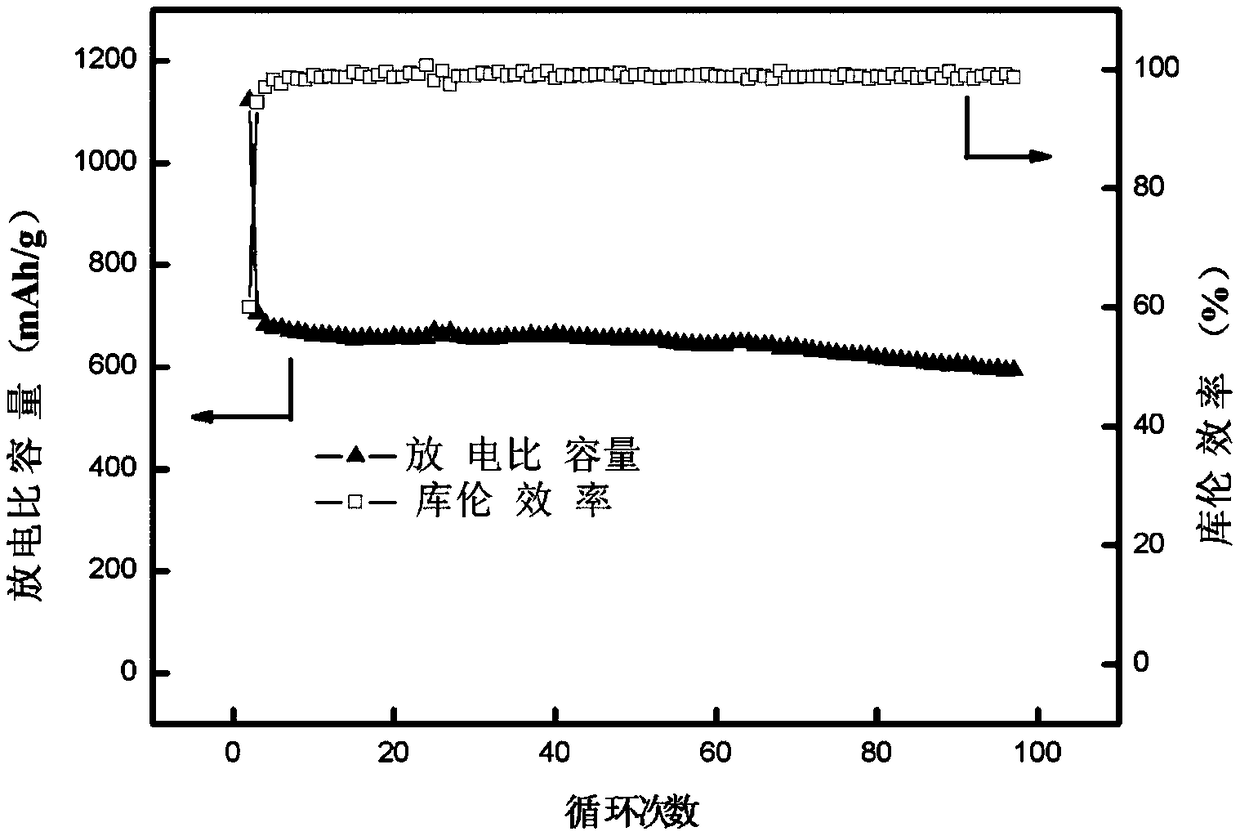

Embodiment 1

[0025] A preparation method of the selenium-heteroatom-doped graphene hollow sphere composite cathode material proposed by the present invention comprises the following steps: respectively preparing graphene oxide aqueous solutions with a mass volume concentration of 1 mg / mL, and a mass volume concentration of 1 mg / mL mL of silicon dioxide dispersion and hydrazine hydrate aqueous solution with a mass volume concentration of 1 mg / mL, wherein, in the silicon dioxide dispersion, the diameter of silicon dioxide is 10 nm; the above graphene oxide aqueous solution, silicon dioxide dispersion, The hydrazine hydrate aqueous solution is mixed according to the volume ratio of 1:1:1, and the ultrasonic dispersion is uniform to obtain a suspension; the suspension is spray-dried, and the feed is fed by a peristaltic pump, the feed speed is 1mL / min, and the feed inlet temperature is 150 ℃, the discharge temperature is 110°C, collect the spray-dried product, put it in a tube furnace under the...

Embodiment 2

[0029] A preparation method of the selenium-heteroatom-doped graphene hollow sphere composite positive electrode material proposed by the present invention comprises the following steps: respectively preparing graphene oxide aqueous solutions with a mass volume concentration of 1 mg / mL and a mass volume concentration of 10 mg / mL mL of silicon dioxide dispersion and a boric acid aqueous solution with a mass volume concentration of 1 mg / mL, wherein, in the silicon dioxide dispersion, the diameter of silicon dioxide is 10 nm; the above-mentioned graphene oxide aqueous solution, silicon dioxide dispersion, boric acid The aqueous solution was mixed according to the volume ratio of 1:1:1, ultrasonically dispersed to obtain a uniform suspension, and then spray-dried, fed by a peristaltic pump, the feeding speed was 1mL / min, the inlet temperature was 250°C, and the outlet temperature was 110°C, collect the above-mentioned spray-dried product, put it in a tube furnace under the protecti...

Embodiment 3

[0031]A preparation method of the selenium-heteroatom-doped graphene hollow sphere composite cathode material proposed by the present invention comprises the following steps: respectively preparing graphene oxide aqueous solutions with a mass volume concentration of 1 mg / mL, and a mass volume concentration of 1 mg / mL mL of silicon dioxide dispersion and a phosphoric acid aqueous solution with a mass volume concentration of 1 mg / mL, wherein, in the silicon dioxide dispersion, the diameter of silicon dioxide is 500 nm; the above-mentioned graphene oxide aqueous solution, silicon dioxide dispersion, phosphoric acid The aqueous solution is mixed according to the volume ratio of 1:1:1, and the suspension is obtained by ultrasonic dispersion; the suspension is spray-dried, fed by a peristaltic pump, the feeding speed is 10mL / min, the inlet temperature is 150°C, and the outlet The material temperature was 110°C, and the spray-dried product was collected, placed in a tube furnace prote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com