Co-N-C/carbon nano tube catalyst, preparation method and application thereof

A carbon nanotube and catalyst technology, which is applied in the field of Co-N-C/carbon nanotube catalyst and its preparation, can solve the problems of increasing the overall cost of the catalyst, increasing the cost of the catalyst, and complicated preparation costs, etc., and achieves excellent electrocatalytic performance for oxygen reduction, The effect of low equipment requirements and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: Prepare Co-N-C / carbon nanotube catalyst with dicyandiamide as carbon and nitrogen source

[0037] S1: 2.0g of CoCl 2 ·6H 2 O and 1.0g of dicyandiamide were dispersed in 20ml of absolute ethanol, ultrasonically dispersed for 25min, dried at 110°C for 12h until it was completely dry, and ground to obtain a powdery mixture;

[0038] S2: Put the mixture into a porcelain boat, place it in a high-temperature tube furnace, feed nitrogen at a rate of 160ml / min, raise the temperature to 650°C at a rate of 6°C / min, keep it warm for 3 hours, cool to room temperature, and grind Obtain black powdery material;

[0039] S3: Put the black powder into 10 mL of hydrochloric acid with a concentration of 1 mol / L, stir at room temperature for 12 hours, filter and dry with suction to obtain the Co-N-C / carbon nanotube catalyst, and the mass of the final product is 0.41 g.

Embodiment 2

[0040] Embodiment 2: Preparation of Co-N-C / carbon nanotube catalyst with melamine as carbon and nitrogen source

[0041] S1: 2.0g of CoCl 2 ·6H 2 O and 4.0 g of melamine were dispersed in 20 ml of absolute ethanol, ultrasonically dispersed for 25 min, dried at 80°C for 24 h, until it was completely dry, and ground to obtain a powdery mixture;

[0042] S2: Put the mixture into a porcelain boat, place it in a high-temperature tube furnace, feed nitrogen at a rate of 130ml / min, raise the temperature to 700°C at a rate of 7°C / min, keep it warm for 2 hours, cool to room temperature, and grind Obtain black powdery material;

[0043] S3: put the black powder into 10 mL of hydrochloric acid with a concentration of 1 mol / L, stir at room temperature for 24 hours, filter and dry with suction to obtain the Co-N-C / carbon nanotube catalyst. The mass of the final product is 0.82 g.

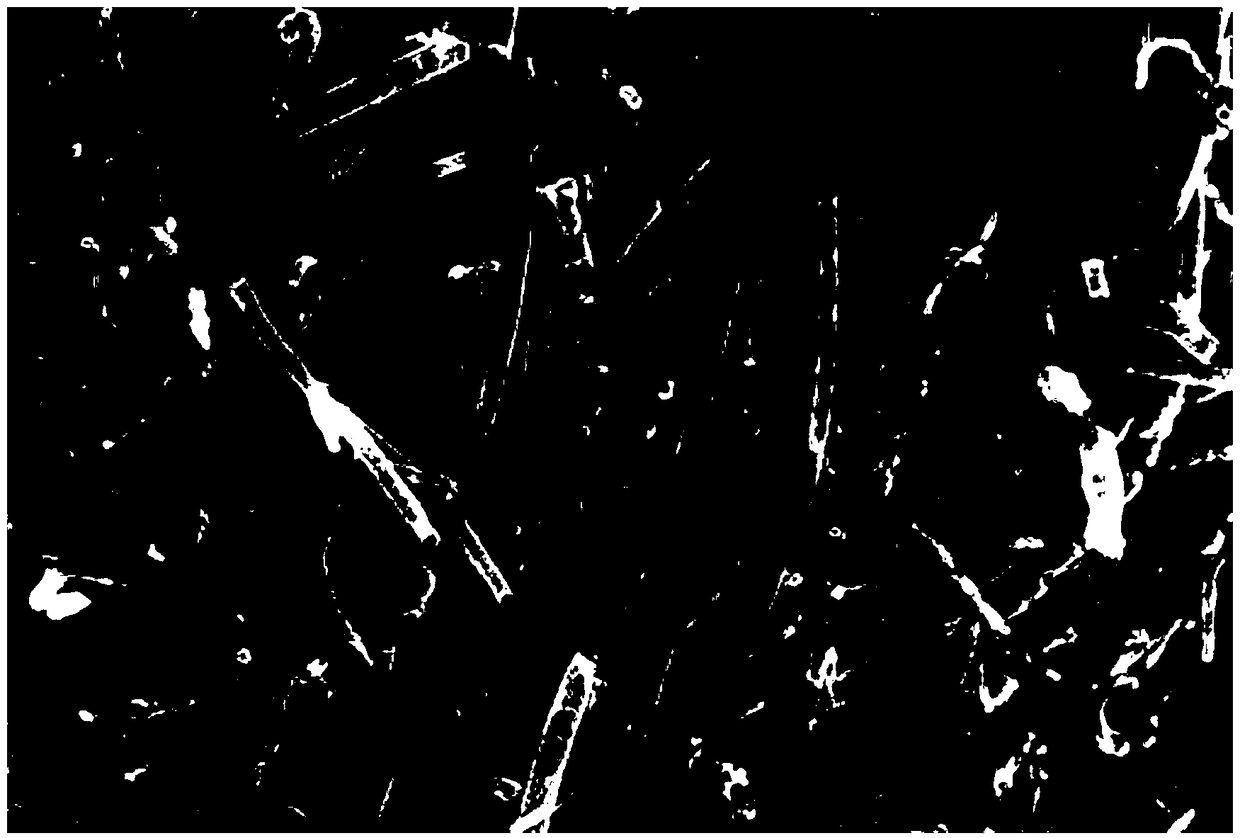

[0044] The SEM of the obtained Co-N-C / carbon nanotube catalyst sample is as figure 1 As shown, the sampl...

Embodiment 3

[0047] Embodiment 3: Preparation of Co-N-C / carbon nanotube catalyst with melamine as carbon and nitrogen source

[0048] S1: 2.0g of CoCl 2 ·6H 2 O and 4.0 g of melamine were dispersed in 20 ml of absolute ethanol, ultrasonically dispersed for 25 min, dried at 80° C. for 24 h, and ground to obtain a powdery mixture;

[0049]S2: Put the powder mixture into a porcelain boat, place it in a high-temperature tube furnace, feed nitrogen at a rate of 120ml / min, raise the temperature to 800°C at a rate of 6°C / min, keep it for 2 hours, and then cool to room temperature , ground into a black powdery material;

[0050] S3: Put the black powder into 10 mL of hydrochloric acid with a concentration of 1 mol / L, stir at room temperature for 12 hours, filter and dry with suction to obtain the Co-N-C / carbon nanotube catalyst, and the mass of the final product is 0.88 g.

[0051] The SEM image of the Co-N-C / carbon nanotube catalyst sample prepared by the above-mentioned preparation method is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com