Application of modified protein for improving viscoelasticity of minced fillet and products of minced fillet

A viscoelastic and modified technology, which is applied in the direction of protein-containing food ingredients, food ingredients as viscosity modifiers, and peptide preparation methods, can solve problems such as limited effects, and achieve significant effects, short time consumption, and stable product properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: Preparation of modified egg white protein sample

[0043]First take fresh eggs to remove the yolk and collect the egg white liquid, remove the eggs and other impurities, beat evenly with a disperser and filter the upper layer of foam; then weigh 0-4g tea polyphenols and dissolve them in 100g deionized water to prepare a concentration of 0% , 1%, 2%, 3%, and 4% tea polyphenol solutions; measure 100 μL of hydrogen peroxide and dissolve it in 100 mL of deionized water to prepare a hydrogen peroxide solution with a volume fraction of 0.1%.

[0044] Weigh 50g of fresh egg white protein solution, measure the protein concentration with the Coomassie brilliant blue method, adjust the protein mass concentration to 10% with phosphate buffer, and adjust the pH value to 7.0, then adjust the concentration to 0%, 1%, 2%, 3 % and 4% tea polyphenol solutions were slowly added to 50mL of egg white protein solution, and then 1mL of hydrogen peroxide solution was added to ea...

Embodiment 2

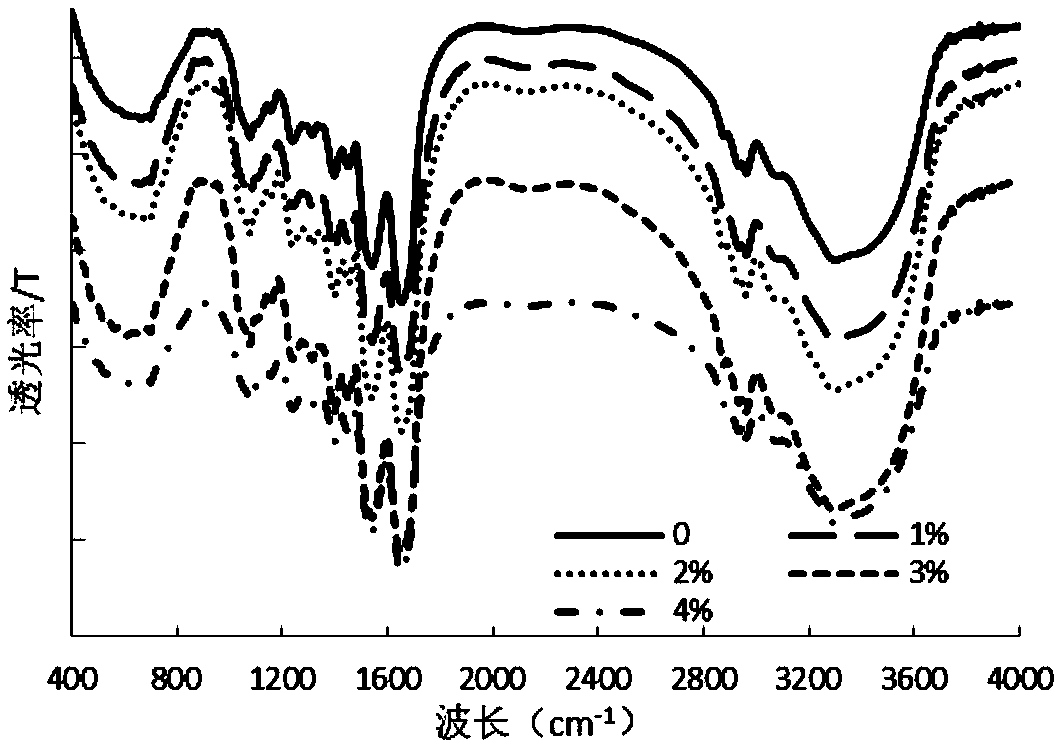

[0046] Example 2: Changes in the secondary structure of egg white protein after modification

[0047] Accurately weigh 3 mg of the sample obtained in Example 1, add 100 mg of finely ground dry potassium bromide, grind it into a uniform dry powder, press it into thin slices, and use a Fourier infrared spectrometer to collect the infrared spectrum of the sample. The changes in the content of each secondary structure were then analyzed. Fourier transform infrared spectrum such as figure 1 As shown, the content of each secondary structure is shown in Table 1.

[0048] Table 1. Effects of different concentrations of tea polyphenols on the secondary structure of egg white protein

[0049]

[0050]

[0051] It can be seen from Table 1 that the secondary structure of the modified protein has changed significantly. The modification method of the present invention destroys the original rigid structure of egg white protein to a certain extent, and the flexible structure increase...

Embodiment 3

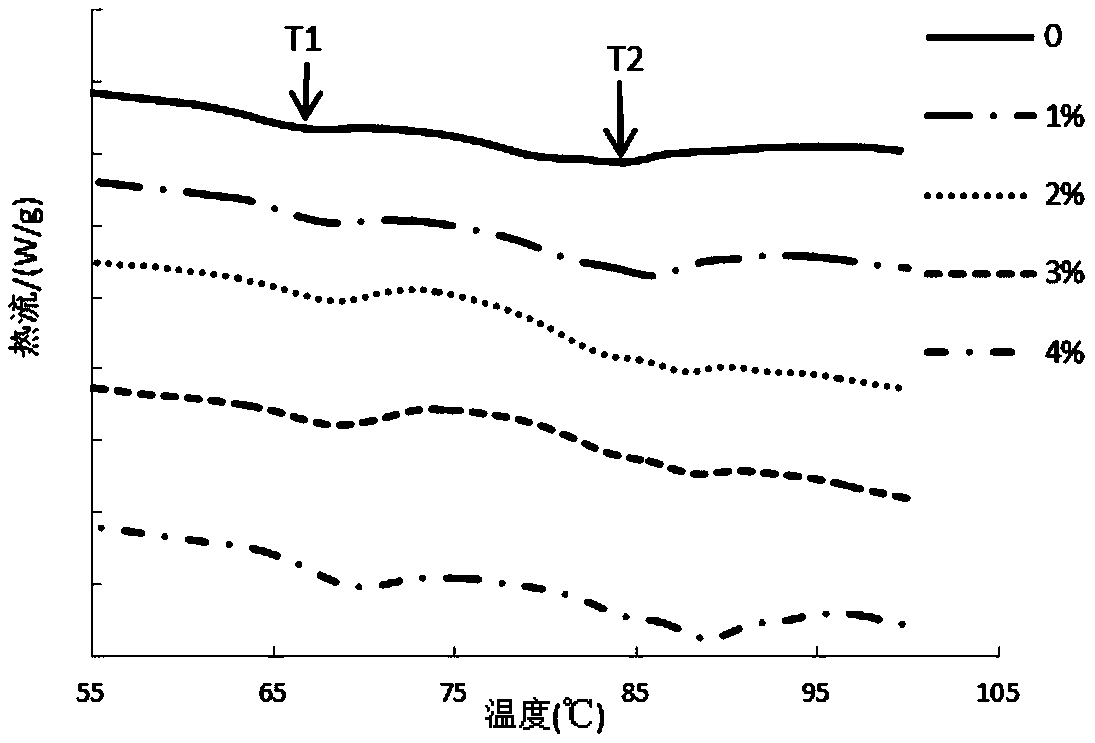

[0052] Example 3: Changes in thermal stability of egg white protein after modification

[0053] Take the modified egg white protein obtained by freeze-drying in Example 1, weigh an appropriate amount of sample, put it into an aluminum crucible, seal it, and use the same empty crucible as a reference, and heat it from 25°C to 105°C at a heating rate of 5°C / min . The whole process is dry N 2 Under the following conditions, the rate of purge gas is 20mL / min, and the rate of protective gas is 60mL / min. The result is as figure 2 shown.

[0054] Such as figure 2 As shown, the two absorption peaks of the modified egg white protein both shift to the right, that is, the protein denaturation temperature increases after modification, indicating that the thermal stability of the protein is enhanced after being modified by the modification method of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com