Mineral separation method for recovering fluorite from flotation tailings of wolframite and scheelite

A technology for flotation tailings and black and white tungsten, applied in flotation, solid separation, etc., can solve the problems of production safety management safety hazards, poor water solubility of collector oleic acid, large amount of soda ash added, etc., and achieve the goal of eliminating residual chemicals Influence and eliminate hidden dangers of acid and alkali production management and improve recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

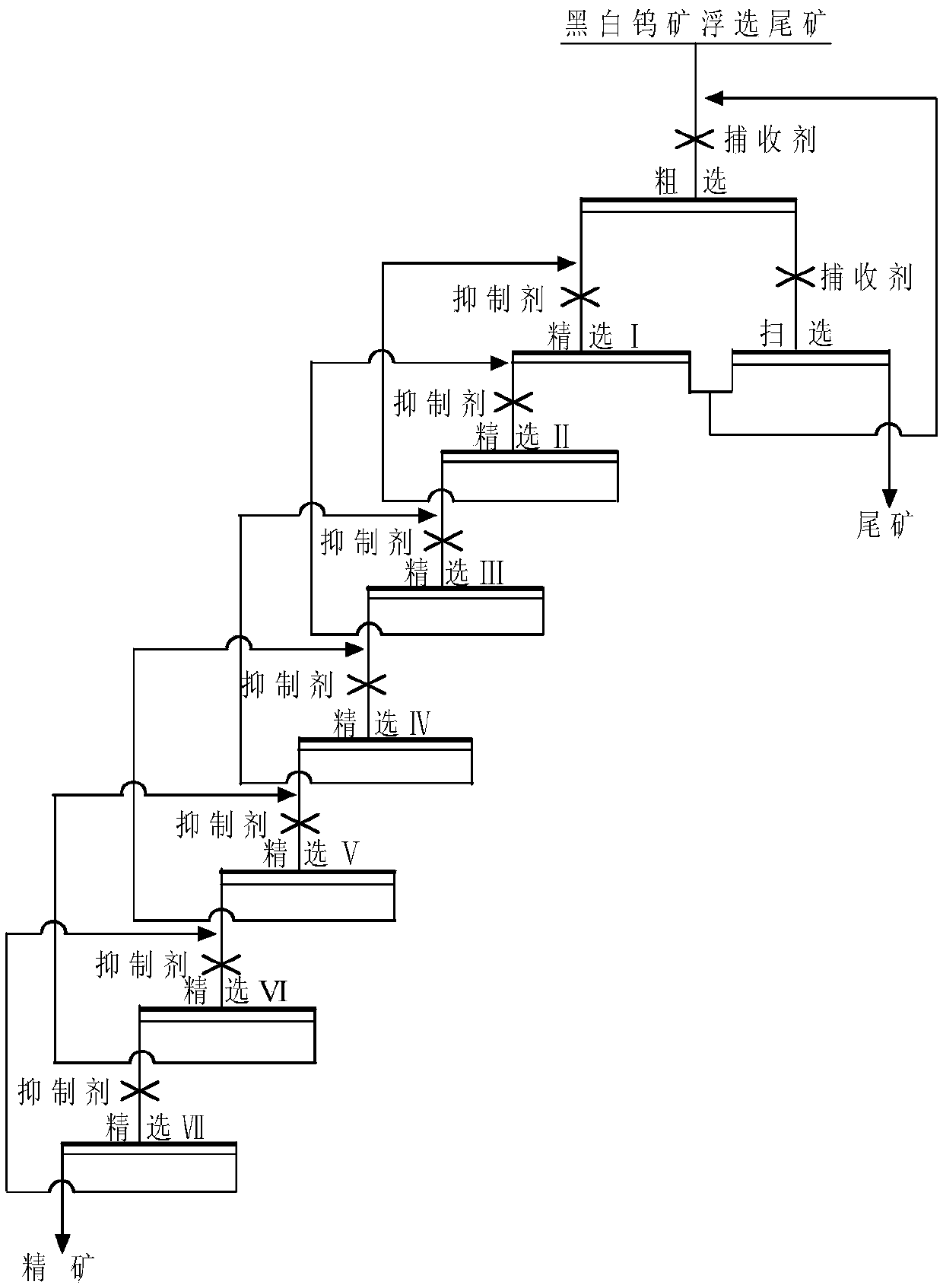

[0050] The flotation tailings of a black and white tungsten mine contain CaF 2 20.37%, CaCO 3 3.51%, SiO 2 47.05%, the flotation process adopts the process of one roughing, one sweeping and seven refining, in which the middle ore from the first selection and sweeping returns to roughing, and the middle ore from the second, third, fourth, fifth, sixth and seventh selections are successively Return to the previous featured job.

[0051] Such as figure 1 Shown, follow the steps below to perform flotation:

[0052] (1) Add modified oleic acid collector to black and white tungsten ore flotation tailings, the addition amount is 400g / t, obtain foam product fluorite coarse concentrate and tailings after a rough separation, the modified oleic acid The collector is a combination of oleic acid, kerosene and octylphenyl polyoxyethylene ether according to the mass ratio of 7:2:1;

[0053] (2) Sweep the tailings obtained after the roughing in step (1), the amount of the modified ole...

Embodiment 2

[0057] The flotation tailings of a black and white tungsten mine contain CaF 2 25.81%, CaCO 3 5.69%, SiO 2 46.62%, the flotation process adopts one roughing, one sweeping and eight refining processes, in which the middle ore from the first selection and sweeping returns to roughing, and the second, third, fourth, fifth, sixth, seventh and eighth selections The middle mine returns to the previous selection operation in turn.

[0058] Follow the steps below for flotation:

[0059] (1) Add modified oleic acid collector to black and white tungsten ore flotation tailings, the addition amount is 600g / t, obtain foam product fluorite coarse concentrate and tailings after a rough separation, the modified oleic acid The collector is a combination of oleic acid, kerosene and octylphenyl polyoxyethylene ether according to the mass ratio of 8:2.5:1;

[0060] (2) Sweep the tailings obtained after the roughing in step (1), the addition of modified oleic acid collector is 80g / t in the ...

Embodiment 3

[0064] The flotation tailings of a black and white tungsten mine contain CaF 2 18.82%, CaCO 3 2.58%, SiO 2 49.72%, the flotation process adopts a process of roughing, sweeping and nine refining, in which the middle ore of the first selection and sweeping returns to roughing, and the second, third, fourth, fifth, sixth, seventh, eighth, and ninth times The middle ore obtained from the concentration returns to the previous concentration operation in turn.

[0065] Follow the steps below for flotation:

[0066] (1) Add modified oleic acid collector to black and white tungsten ore flotation tailings, the addition amount is 300g / t, obtain foam product fluorite coarse concentrate and tailings after a rough separation, the modified oleic acid The collector is a combination of oleic acid, kerosene and octylphenyl polyoxyethylene ether according to a mass ratio of 10:3:1;

[0067] (2) Sweep the tailings obtained after the roughing in step (1), the amount of modified oleic acid c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com