Preparation device and method for polysilazane

A technology of polysilazane and filter device, which is applied in the field of polysilazane preparation equipment, can solve the problems of low reaction yield and difficult large-scale stable preparation of polysilazane, and achieve the elimination of easy hydrolysis and production capacity Improvement, small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

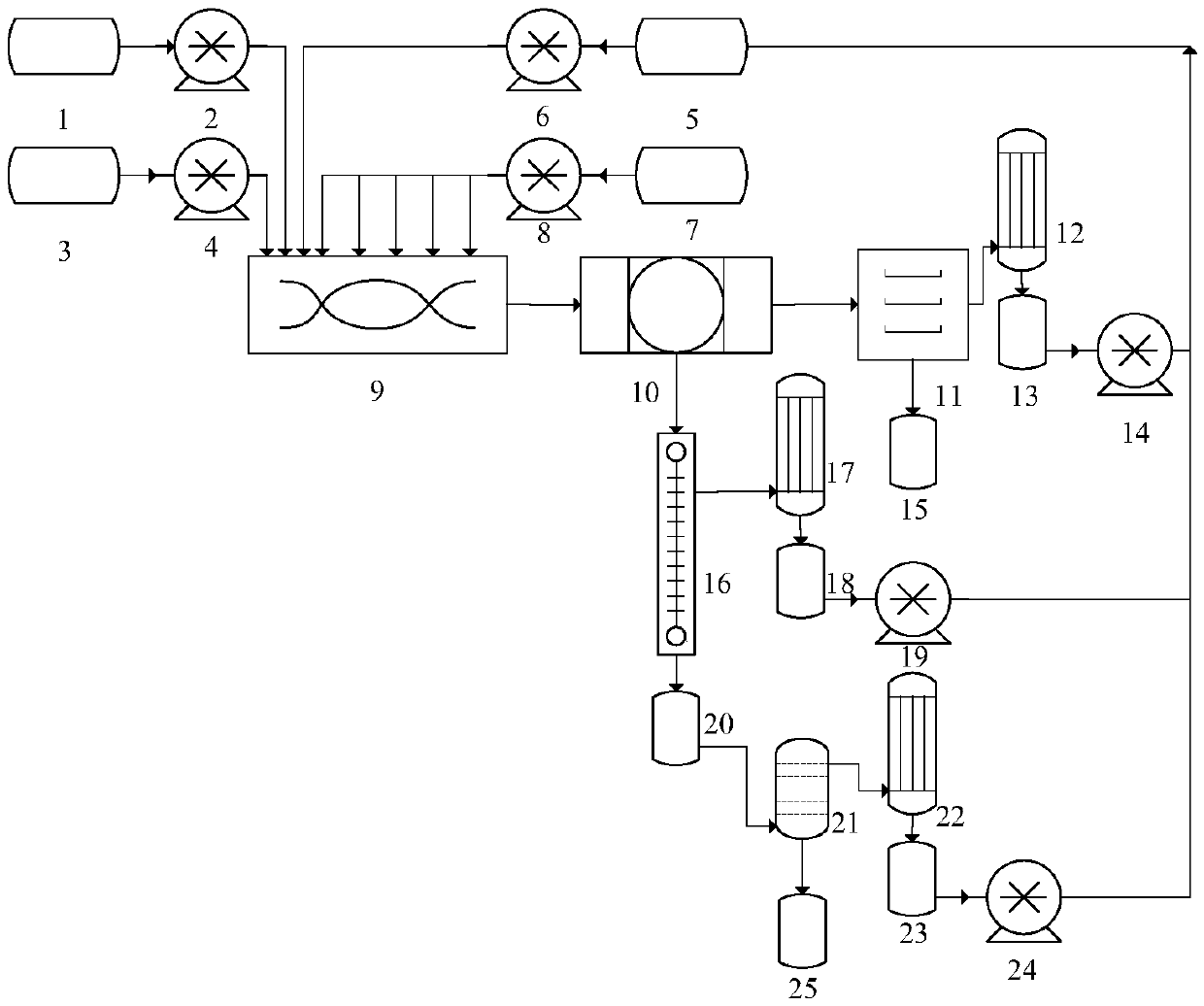

[0028] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

[0029] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0030] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

[0031]The preferred embodiment of the present invention provides a special device for polysilazane, which includes a feeding device for raw materials (chlorosilanes of different structures, ammonia and an inert solvent), a tubular reaction device, a filter device, a drying device, Distillation device and rectification device, the whole special ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com