Preparation method of photocatalytic material by in-situ compositing zinc ferrite nano-rods with lamellar TiO2

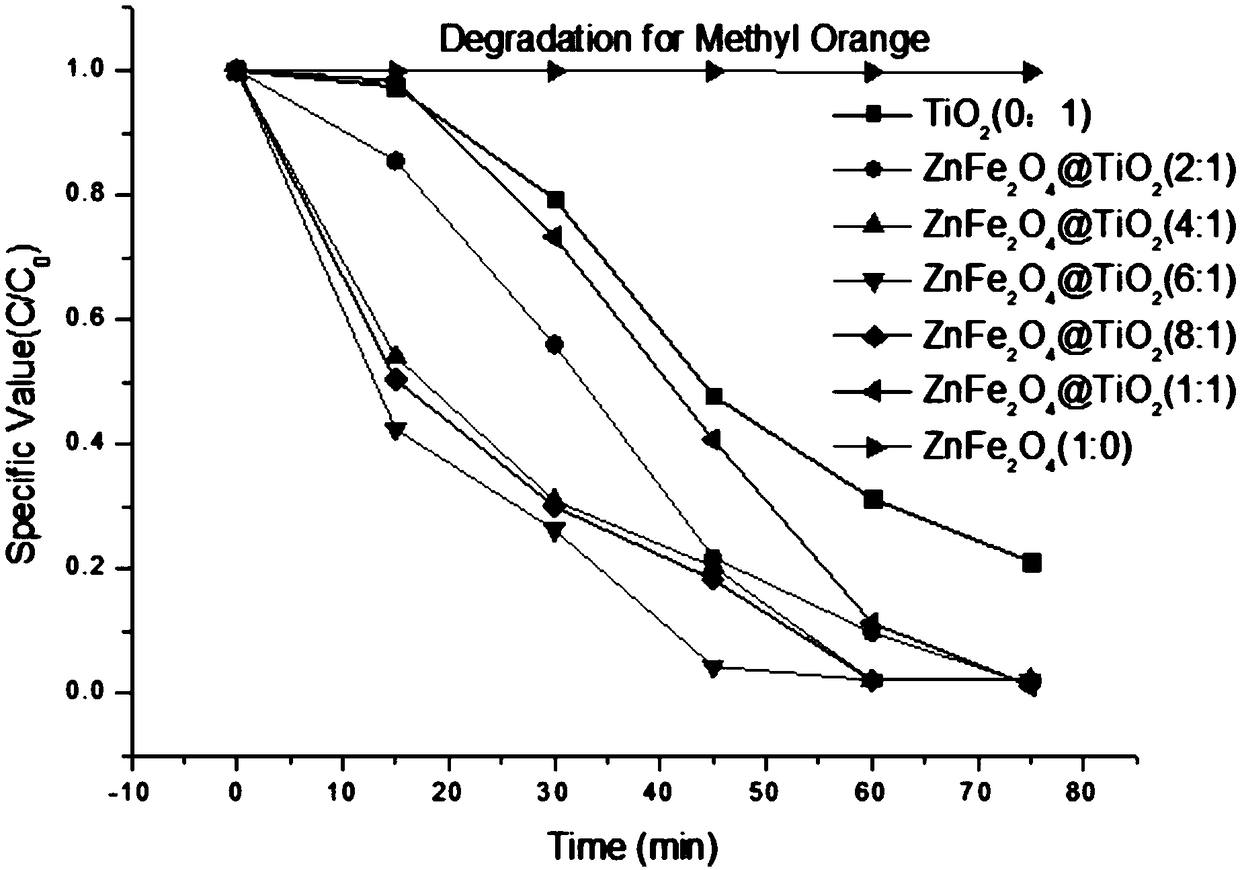

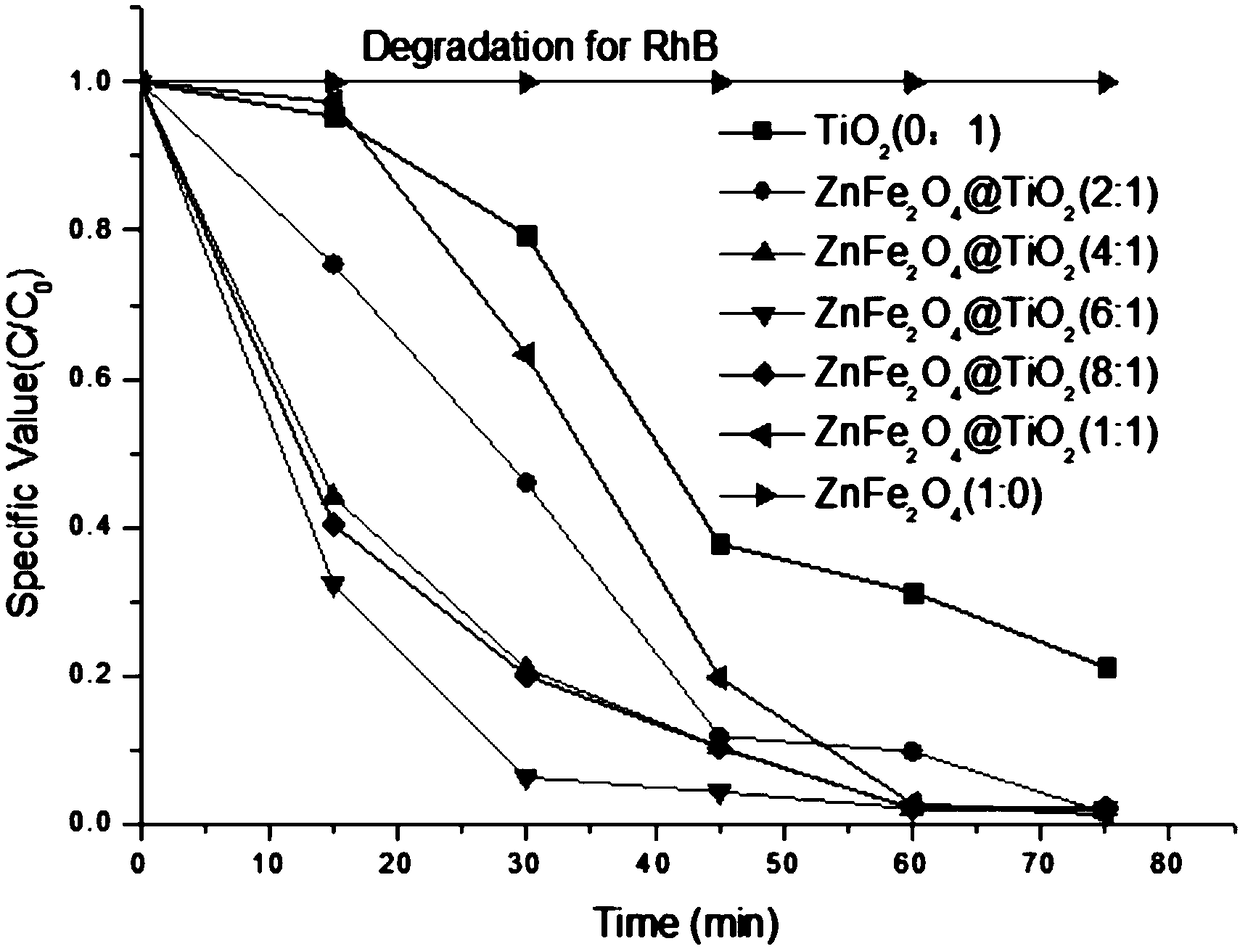

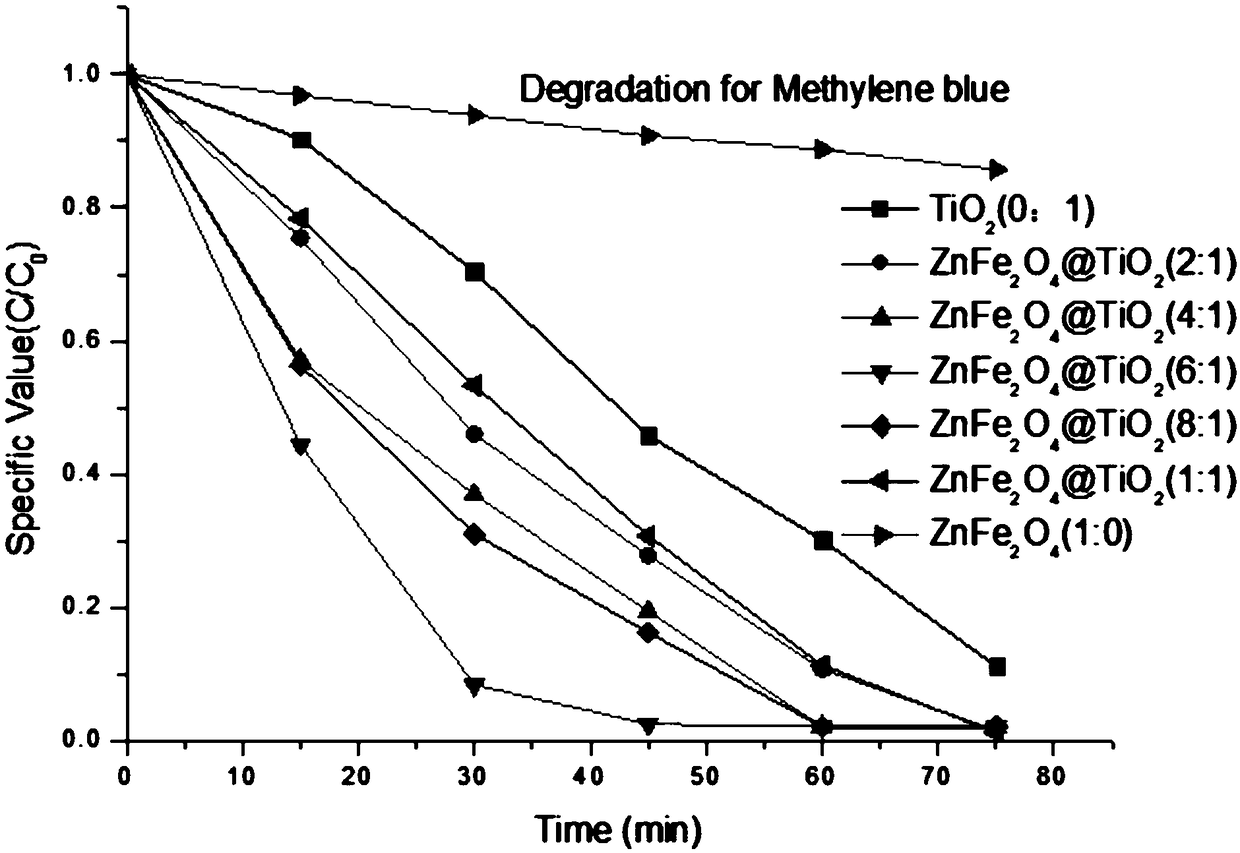

A photocatalytic material and an in-situ composite technology are applied in the field of photocatalytic material preparation to achieve the effects of simple and easy method and improved ability to degrade dyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1: Preparation of Nanorod Zinc Ferrite

[0035] (1) take zinc chloride and ferrous chloride tetrahydrate and add in the 80% ethylene glycol aqueous solution that fills a certain proportion, then magnetic stirring mixes;

[0036] (2) Transfer to a Teflon reaction kettle, react in a hydrothermal reaction kettle at 175°C-185°C for 24 hours, and obtain a light yellow solid, which is then washed by centrifugation and dried overnight in a vacuum environment at 80°C to obtain zinc ferrite Precursor complex;

[0037] (3) transfer the zinc ferrite precursor compound into a crucible, put it into a muffle furnace for calcination at a high temperature of 500° C. for three hours, and obtain nanorod zinc ferrite crystals;

[0038] Step 2: Preparation of nanorod zinc ferrite in situ composite sheet titanium dioxide photocatalytic material

[0039](1) 0.5g cetyltrimethylammonium bromide is taken and dissolved in ethanol and amyl alcohol mixed solution with a volume ratio of 4:1,...

Embodiment 2

[0045] Step 1: same as Step 1 in Example 1;

[0046] Step 2: Preparation of nanorod zinc ferrite in situ composite sheet titanium dioxide photocatalytic material

[0047] (1) 0.5g cetyltrimethylammonium bromide is taken and dissolved in ethanol and amyl alcohol mixed solution with a volume ratio of 4:1, stirred for 20min to make it completely dissolved to obtain a mixed alcohol solution of ethanol and amyl alcohol;

[0048] (2) Weighing 1.2g of the rod-shaped zinc ferrite nanomaterial prepared in step 1 and putting it into the alcohol solution mixed in (1), stirring for 30min to obtain a uniformly mixed mixture;

[0049] (3) Slowly add 5ml of tetrabutyl titanate liquid, 3ml of hydrofluoric acid and 8ml of deionized water into the homogeneously mixed mixture in (2), respectively, and continue magnetic stirring for 30min. After the stirring is completed, transfer it to the reactor and react in an oven at 180°C for 12 hours;

[0050] (4) After the reaction is completed and cool...

Embodiment 3

[0053] Step 1: same as Step 1 in Example 1;

[0054] Step 2: Preparation of nanorod zinc ferrite in situ composite sheet titanium dioxide photocatalytic material

[0055] (1) 0.5g cetyltrimethylammonium bromide is taken and dissolved in ethanol and amyl alcohol mixed solution with a volume ratio of 4:1, stirred for 20min to make it completely dissolved to obtain a mixed alcohol solution of ethanol and amyl alcohol;

[0056] (2) Weighing 1.8g of the rod-shaped zinc ferrite nanomaterial prepared in step 1 and putting it into the alcohol solution mixed in (1), stirring for 30min to obtain a uniformly mixed mixture;

[0057] (3) Slowly add 5ml of tetrabutyl titanate liquid, 3ml of hydrofluoric acid and 8ml of deionized water to the homogeneously mixed mixture in (2), respectively, and continue magnetic stirring for 30min. After the stirring is completed, transfer it to the reaction kettle React in an oven at 180°C for 12 hours;

[0058] (4) After the reaction is completed and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com