A block copolymer nanocomposite antibacterial material and its preparation method and application

A technology of block copolymer and antibacterial material, applied in the field of block copolymer nanocomposite antibacterial material and its preparation, can solve the problems of uncontrollable synthesis of block copolymer and single function of antibacterial material, and achieve good cell compatibility Sex, great flexibility and inclusiveness, antibacterial properties adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

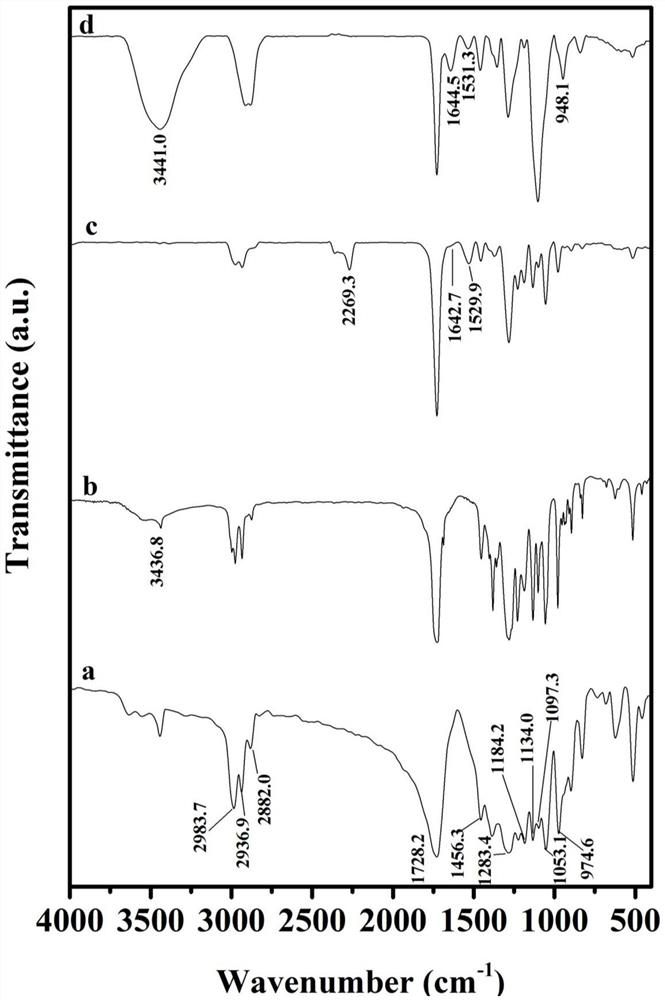

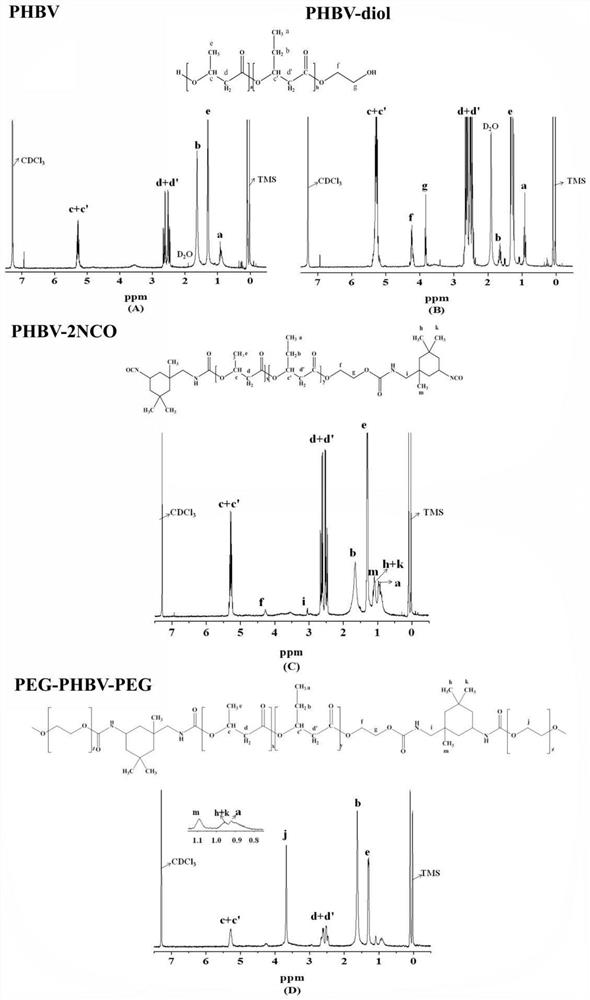

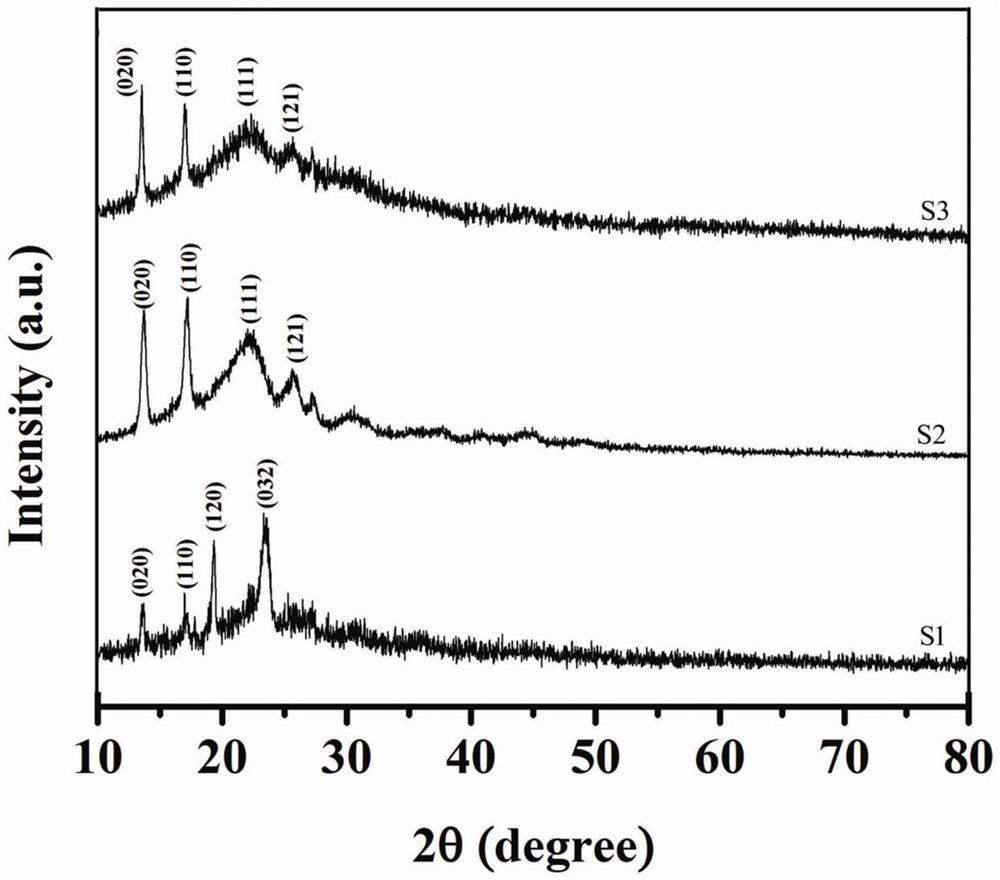

Embodiment 1

[0066] 2g PHBV (number average molecular weight 1.85×10 5 ) was dissolved in 20mL diglyme, heated to 140°C, N 2 Protection, add 4mL ethylene glycol, stir for 5min, add 0.02g dibutyltin dilaurate, stir for 5min, add dropwise 0.08g dibutyltin dilaurate, react for 7.5h, settle in cold ethanol, repeat 6 times, vacuum filter, vacuum Dry for 24 hours to obtain PHBV-diol. Take 0.0001mol PHBV-diol, dissolve in 15mL of anhydrous 1,2-dichloroethane, N 2 protection, warming up to 75°C, adding 0.0002mol IPDI, stirring for 5min, adding 0.02g dibutyltin dilaurate, stirring for 3h, cooling to room temperature, adding n-hexane and diethyl ether mixture (the volume ratio of n-hexane and diethyl ether is 1:1 ) sedimentation, washed repeatedly 3 times, filtered, and vacuum-dried at 40°C for 12 hours to obtain PHBV-2NCO. Dissolve 0.0001mol PHBV-2NCO in 15mL of anhydrous 1,2-dichloroethane, N 2 For protection, add 0.0002, 0.0003 and 0.0004mol PEG (weight average molecular weight 2000) respecti...

Embodiment 2

[0068] 2g PHBV (number average molecular weight 1.85×10 5 ) was dissolved in 20mL diglyme, heated to 140°C, N 2 For protection, add 4mL ethylene glycol, stir for 5min, add 0.02g dibutyltin dilaurate, stir for 5min, add 0.10g dibutyltin dilaurate, react for 9h, settle in cold methanol, repeat 3 times, vacuum filter, vacuum dry for 24h . Take 0.0001mol product and dissolve in 10mL anhydrous 1,2-dichloroethane, N 2 Protect, heat up to 75°C, add 0.0002mol IPDI, stir for 5min, add 0.02g dibutyltin dilaurate, stir for 5h, cool to room temperature, add n-hexane and petroleum ether mixture (the volume ratio of n-hexane and petroleum ether is 1 : 1) settling, washing repeatedly 6 times, filtering, vacuum drying at 40°C for 12h, to obtain PHBV-2NCO. Dissolve 0.0001mol PHBV-2NCO in 10mL of anhydrous 1,2-dichloroethane, N 2 For protection, add 0.0002mol PEG (weight average molecular weight 1000) respectively, heat up to 75°C, add 1wt% dibutyltin dilaurate, stir for 3h, cool to room te...

Embodiment 3

[0070] 2g PHBV (number average molecular weight 1.85×10 5 ) was dissolved in 10mL diglyme, heated to 140°C, N 2 Protection, add 3mL butanediol, stir for 5min, add 0.02g dibutyltin dilaurate, stir for 5min, add dropwise 0.08g dibutyltin dilaurate, react for 7.5h, settle in cold ethanol, repeat 6 times, acetone, water wash, vacuum Suction filtration and vacuum drying for 24 hours to obtain PHBV-diol. Take 0.0001mol PHBV-diol, dissolve in 15mL of anhydrous 1,2-dichloroethane, N 2 Protect, heat up to 75°C, add 0.00026molIPDI, stir for 5min, add 0.01g stannous octoate, stir for 3h, cool to room temperature, add n-hexane and petroleum ether mixture (n-hexane and petroleum ether volume ratio 1:1) to settle, Repeatedly washed 6 times, filtered, and vacuum dried at 40°C for 12 hours to obtain PHBV-2NCO. Dissolve 0.0001mol PHBV-2NCO in 15mL of anhydrous 1,2-dichloroethane, N 2 For protection, add 0.0002mol PEG (weight average molecular weight 2000) respectively, heat up to 75°C, add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com