Method for preparing phosphorus modified ZSM-5 molecular sieve with hierarchical pores

A ZSM-5, molecular sieve technology, applied in molecular sieve catalysts, including molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of low yield of low-carbon olefins, low catalyst cracking activity, etc., and achieve high selectivity and good industrial application. Prospects and economic value, the effect of low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The embodiment of the present invention provides a method for preparing a phosphorus-modified ZSM-5 molecular sieve with hierarchical pores, comprising the following steps:

[0039] (1) 281.6g H 2 O, 11.9g NaOH, 169.5g TPAOH (concentration 25wt%) and 1.57g pseudo-boehmite (Al 2 o 3 %: 65wt%) were mixed into a solution, and then 466.4g of silica sol and 1.24g of boric acid were gradually added to the above solution in batches under full stirring and vigorously shaken at room temperature for 1 hour to obtain the molar ratio in the mixed sol:

[0040] Na 2 O:SiO 2 :Al 2 o 3 :B 2 o 3 :OSDA:H 2 O=0.075:1:0.0048:0.0198:0.1:20

[0041] Then the obtained mixed sol was placed in a PTFE-lined stainless steel reaction kettle, crystallized at 160°C for 72 hours, the product was filtered and washed until the pH value was 7-8, dried at 120°C for 12 hours, and calcined at 550°C for 2 hours to obtain NaZSM-5 molecular sieve.

[0042] (2) Use 10g of the NaZSM-5 molecular siev...

Embodiment 2-8

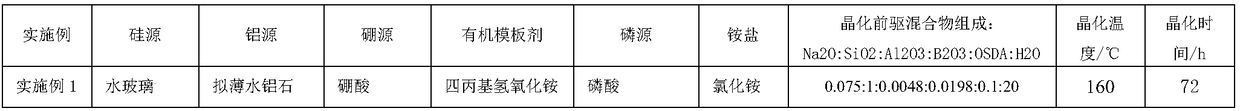

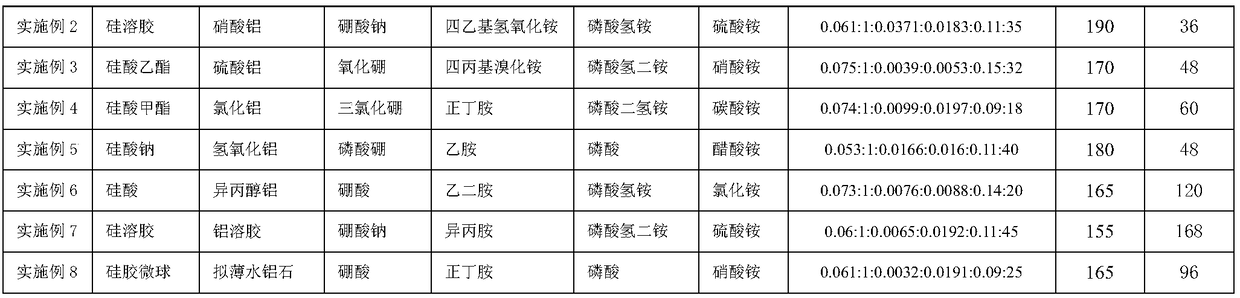

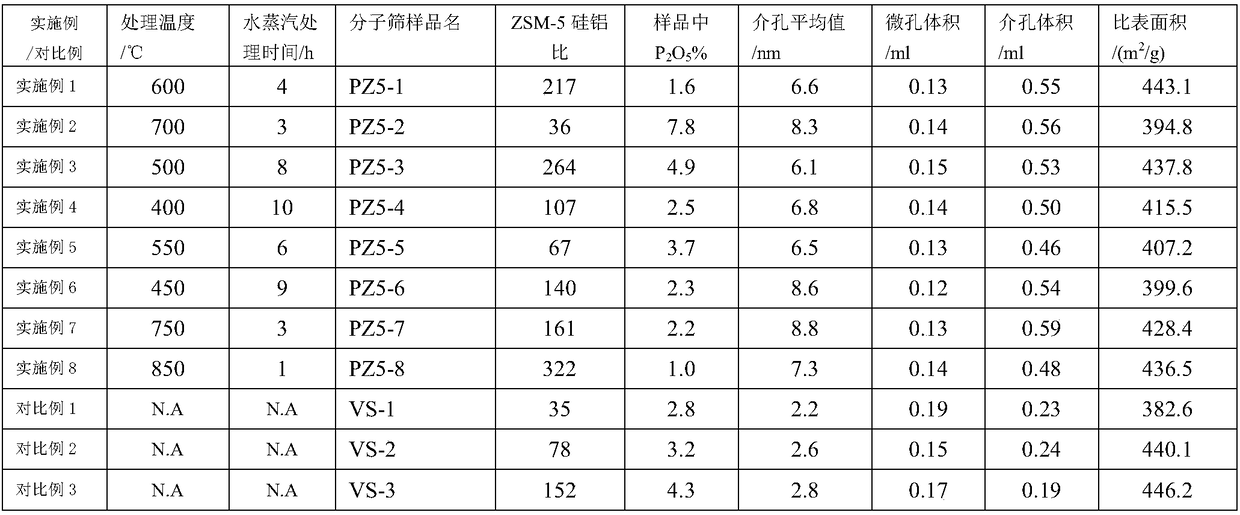

[0045] Embodiments 2-8 of the present invention respectively provide a preparation method of a phosphorus-modified ZSM-5 molecular sieve with hierarchical pores, the selected silicon source, aluminum source, boron source, organic template agent, phosphorus source and ammonium salt The types are shown in Table 1, prepared by the same process as in Example 1, the composition of the obtained synthetic molecular sieve crystallization precursor mixture is shown in Table 1 and Table 2, and the physicochemical characterization parameters of the obtained product are shown in Table 2.

[0046] Table 1

[0047]

[0048]

[0049] Table 2

[0050]

Embodiment 9-19

[0052] Examples 9-16 of the present invention respectively provide a method for using samples PZ5-1 to PZ5-8 prepared in Examples 1-8 as catalysts to catalytically crack naphtha to produce ethylene and propylene. Examples 17-19 of the present invention A method for using the samples VS-1~VS-3 prepared in Comparative Examples 1-3 as a catalyst to catalyze the cracking of naphtha to produce ethylene and propylene is provided, and the catalyst samples PZ5-1~PZ5-8 are tested by this method Evaluation was performed with VS-1 to VS-3.

[0053] The catalyst was evaluated in a continuous flow fixed-bed reactor. The composition of the naphtha raw material is shown in Table 3, and the evaluation conditions and reaction results can be seen in Table 4. The material of the reactor is stainless steel, with an inner diameter of 19 mm and a built-in thermocouple sleeve with an outer diameter of 6 mm. The loading amount of the catalyst is 10g, and the particle size is 20-40 mesh. Naphtha and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com