Heteroatom doped porous carbon membrane as well as preparation method and application thereof

A technology of heteroatom and porous carbon is applied in the field of self-supporting heteroatom doped porous carbon membrane and its preparation, which can solve the problems of difficult preparation of carbon membrane materials, and achieve the effects of easy large-scale preparation, high electrical conductivity and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Preparation of poly(3-cyanomethyl-1-vinylimidazole) trifluoromethanesulfonimide ionic liquid:

[0054] In a 250mL round-bottomed flask, 9.4g of vinylimidazole and 12g of bromoacetonitrile were dissolved in 100mL of ethanol solution and reacted at 40°C for 24 hours to obtain a white 3-cyanomethyl-1-vinylimidazole ionic liquid monomer. Yield: 95%. Take 10 g of the ionic liquid monomer prepared above, dissolve it in dimethylformamide, add 0.2 g of azobisisobutyronitrile, and react at 70 ° C for 48 hours to obtain white poly(3-cyanomethyl-1 -vinylimidazole) bromide ionic liquid. Weigh 10g of poly(3-cyanomethyl-1-vinylimidazole) bromide ionic liquid, dissolve it in 1000mL of deionized water, add 13g of lithium trifluoromethanesulfonyl imide, and stir at room temperature for 4 hours to obtain the target Polyionic liquid, poly(3-cyanomethyl-1-vinylimidazole) trifluoromethanesulfonimide ionic liquid.

[0055] (2) Preparation of polymer composite membrane:

[0056] Disso...

Embodiment 2

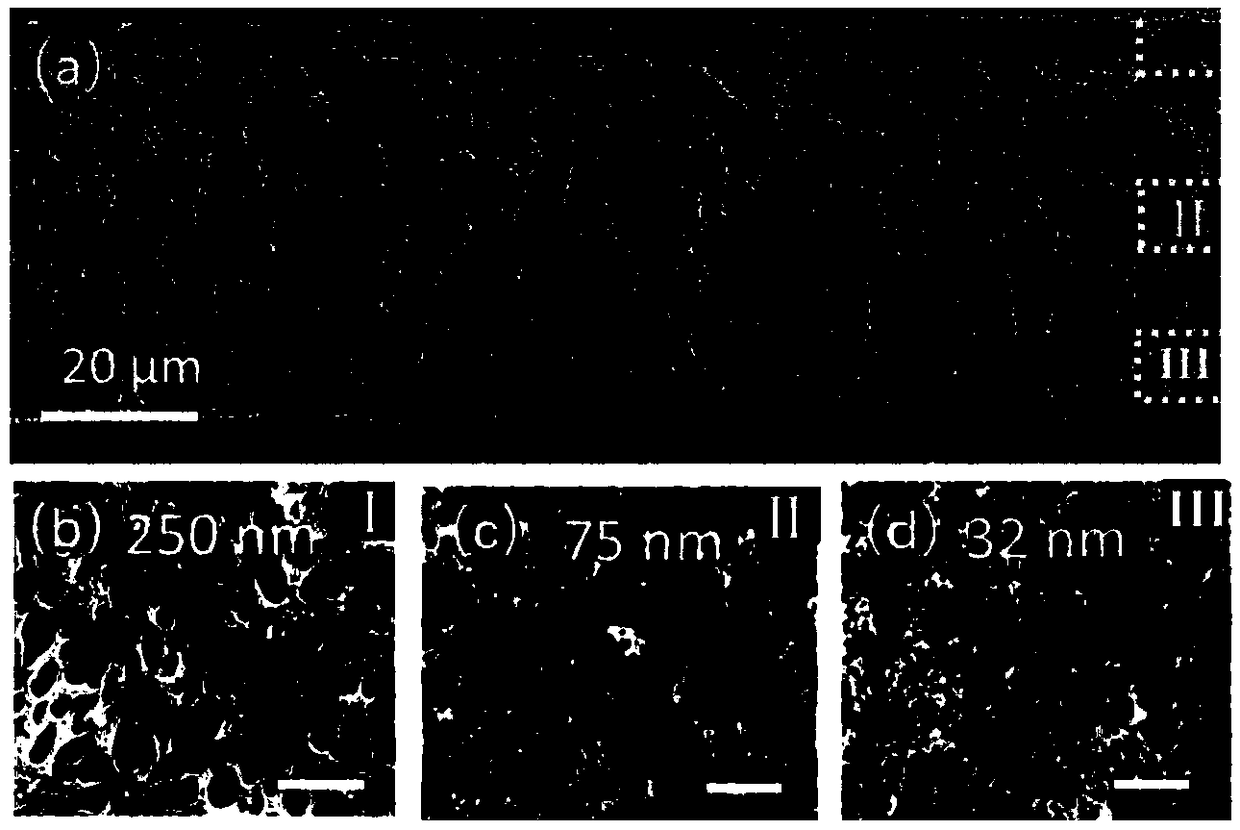

[0059] 1 g of the polyionic liquid prepared in Example 1 and 0.18 g of polyacrylic acid with a molecular weight of 250,000 KDa were dissolved, dispersed in 10 mL of dimethylformamide, poured on a glass plate, and dried at 100° C. for 8 hours. Then, immerse in 0.1% ammonia solution and leave it for 2 hours to obtain a polymer composite film. Under the protection of nitrogen, the obtained polymer film is carbonized at 1000 ° C for 4 hours to obtain a porous nitrogen-doped carbon film. image 3 shown.

Embodiment 3

[0061] (1) Preparation of poly(3-cyanomethyl-1-vinylimidazole) hexafluorophosphate ionic liquid:

[0062] In a 250mL round-bottomed flask, 9.4g of vinylimidazole and 12g of bromoacetonitrile were dissolved in 100mL of ethanol solution and reacted at 40°C for 24 hours to obtain a white 3-cyanomethyl-1-vinylimidazole ionic liquid monomer. Yield: 95%. Take 10 g of the 3-cyanomethyl-1-vinylimidazole ionic liquid monomer prepared above, dissolve it in dimethylformamide, add 0.2 g of azobisisobutyronitrile, and react at 70°C for 48 hours to obtain White polyvinylimidazolium bromide ionic liquid. Weigh 10g of poly(3-cyanomethyl-1-vinylimidazole) bromide ionic liquid, dissolve it in 1000mL of deionized water, add 10g of potassium hexafluorophosphate, and stir at room temperature for 4 hours to obtain the target polyionic liquid, Poly(3-cyanomethyl-1-vinylimidazole) hexafluorophosphate ionic liquid.

[0063] (2) Preparation of polymer composite membrane:

[0064] Dissolve 1 g of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com