Cement grinding aid and preparation method thereof

A cement grinding aid, water-based technology, applied in the field of cement grinding aid and its preparation, can solve the problems of cement quality and durability, large fluctuations in product performance, insufficient layered settlement, etc., and achieve low price and simple preparation method Easy to operate and improve the effect of powder grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

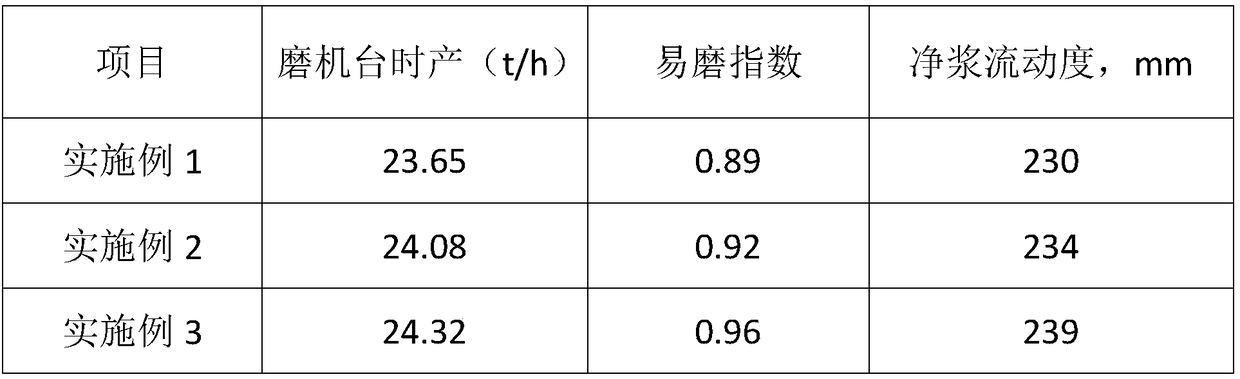

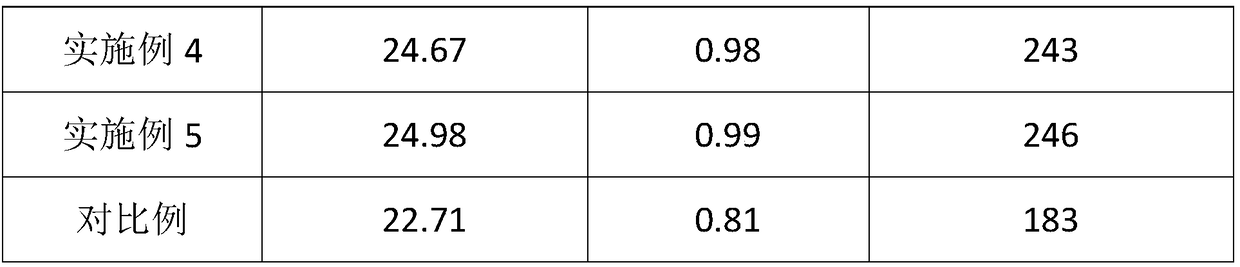

Examples

Embodiment 1

[0024] A cement grinding aid is prepared from the following raw materials in parts by weight: 50 parts of water-based polyhydroxy copolymer and 30 parts of modified hyperbranched polyethyleneimine.

[0025] The preparation method of the water-based polyhydroxyl copolymer comprises the following steps: 20 g of triethanolamine oleic acid soap, 10 g of allyl succinimidyl carbonate, 20 g of eugenol rutinoside, and 20 g of bistrimethylsilylated vinyl Dissolve 10g of phosphate ester in 100g of dimethyl sulfoxide to form a solution, then add 2g of azobisisobutyronitrile into the solution, place it in a microwave oven, and carry out microwave polymerization reaction under a nitrogen atmosphere for 10 minutes, take it out after the reaction, and pour it into acetone The polymer was precipitated out, filtered with suction, put into a vacuum oven and baked at 60° C. for 10 hours to obtain a polyhydroxy copolymer; the microwave polymerization polymerization condition was: microwave power 5...

Embodiment 2

[0029] A cement grinding aid is prepared from the following raw materials in parts by weight: 53 parts of water-based polyhydroxy copolymer and 33 parts of modified hyperbranched polyethyleneimine.

[0030] The preparation method of the water-based polyhydroxyl copolymer comprises the following steps: 20 g of triethanolamine oleic acid soap, 10 g of allyl succinimidyl carbonate, 20 g of eugenol rutinoside, and 20 g of bistrimethylsilylated vinyl Dissolve 10 g of phosphate ester in 115 g of N,N-dimethylformamide to form a solution, then add 2.5 g of azobisisoheptanonitrile to the solution, place it in a microwave oven, and carry out microwave polymerization reaction under a helium atmosphere for 11 minutes. After the reaction, take it out, pour it into acetone to precipitate the polymer, filter it with suction, put it in a vacuum oven and dry it at 63°C for 11 hours to obtain a polyhydroxy copolymer; the microwave polymerization polymerization condition is: microwave power 600W....

Embodiment 3

[0034] A cement grinding aid is prepared from the following raw materials in parts by weight: 55 parts of water-based polyhydroxy copolymer and 35 parts of modified hyperbranched polyethyleneimine.

[0035] The preparation method of the water-based polyhydroxyl copolymer comprises the following steps: 20 g of triethanolamine oleic acid soap, 10 g of allyl succinimidyl carbonate, 20 g of eugenol rutinoside, and 20 g of bistrimethylsilylated vinyl Dissolve 10g of phosphate ester in 125g of N-methylpyrrolidone to form a solution, then add 3g of azobisisobutyronitrile into the solution, place it in a microwave oven, and carry out microwave polymerization reaction under neon gas atmosphere for 12 minutes, take it out after the reaction, pour Put the polymer in acetone to precipitate the polymer, filter it with suction, put it in a vacuum drying oven and bake it at 65° C. for 13 hours to obtain a polyhydroxy copolymer; the microwave polymerization polymerization condition is: microwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com