Heat-insulating wear-resistant quartz ceramic

A technology of quartz ceramics and zeolite powder, applied in the field of heat-insulating and wear-resistant quartz ceramics, can solve the problems of increased use cost, general heat insulation, poor wear resistance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

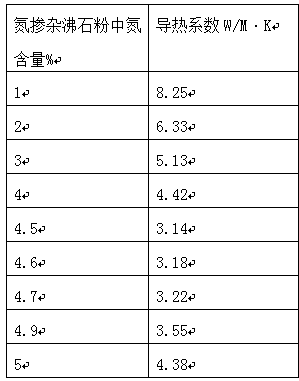

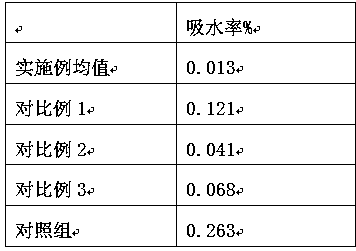

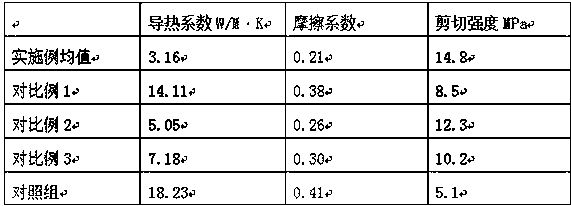

[0019] A heat-insulating and wear-resistant quartz ceramic, the heat-insulating and wear-resistant quartz ceramic contains 6.3% by mass of nitrogen-doped zeolite powder and 16.3% of external additives, and the balance is quartz, and the nitrogen-doped zeolite powder contains nitrogen The element mass percentage is 4.5%.

[0020] Further, the preparation method of the nitrogen-doped zeolite powder is:

[0021] (1) Pretreatment: Disperse zeolite powder evenly in deionized water to prepare a zeolite powder dispersion with a mass fraction of 8.5%, soak at 70°C for 2 hours, then stir at 2000r / min for 20min, and then centrifuge 12min, centrifuge at a speed of 1200r / min, then carry out suction filtration, and dry to constant weight; evenly disperse the dried zeolite powder into an acidic cerium chloride solution, heat to 46°C, and stir at a speed of 250r / min for 40min , then stand still for 2 hours, then filter, wash with deionized water, and dry to constant weight to obtain pretrea...

Embodiment 2

[0030] A heat-insulating and wear-resistant quartz ceramic, the heat-insulating and wear-resistant quartz ceramic contains 7.0% by mass of nitrogen-doped zeolite powder and 16.5% of external additives, and the balance is quartz, and nitrogen in the nitrogen-doped zeolite powder The element mass percentage is 4.6%.

[0031] Further, the preparation method of the nitrogen-doped zeolite powder is:

[0032] (1) Pretreatment: Disperse zeolite powder evenly in deionized water to prepare a zeolite powder dispersion with a mass fraction of 8.5%, soak at 70°C for 2 hours, then stir at 2000r / min for 20min, and then centrifuge 12min, centrifuge at a speed of 1200r / min, then carry out suction filtration, and dry to constant weight; evenly disperse the dried zeolite powder into an acidic cerium chloride solution, heat to 46°C, and stir at a speed of 250r / min for 40min , then stand still for 2 hours, then filter, wash with deionized water, and dry to constant weight to obtain pretreated ze...

Embodiment 3

[0041] A heat-insulating and wear-resistant quartz ceramic, the heat-insulating and wear-resistant quartz ceramic contains 6.6% by mass of nitrogen-doped zeolite powder and 16.4% of external additives, and the balance is quartz, and nitrogen in the nitrogen-doped zeolite powder The element mass percentage is 4.55%.

[0042] Further, the preparation method of the nitrogen-doped zeolite powder is:

[0043] (1) Pretreatment: Disperse zeolite powder evenly in deionized water to prepare a zeolite powder dispersion with a mass fraction of 8.5%, soak at 70°C for 2 hours, then stir at 2000r / min for 20min, and then centrifuge 12min, centrifuge at a speed of 1200r / min, then carry out suction filtration, and dry to constant weight; evenly disperse the dried zeolite powder into an acidic cerium chloride solution, heat to 46°C, and stir at a speed of 250r / min for 40min , then stand still for 2 hours, then filter, wash with deionized water, and dry to constant weight to obtain pretreated z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com