A kind of method for synthesizing cordierite powder at low temperature with anhydrous magnesium chloride as molten salt base

A technique for synthesizing cordierite with anhydrous magnesium chloride, applied in the direction of silicate, alkaline earth metal silicate, etc., can solve problems such as complex preparation process, achieve good chemical stability, good repeatability, and improve the effect of product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

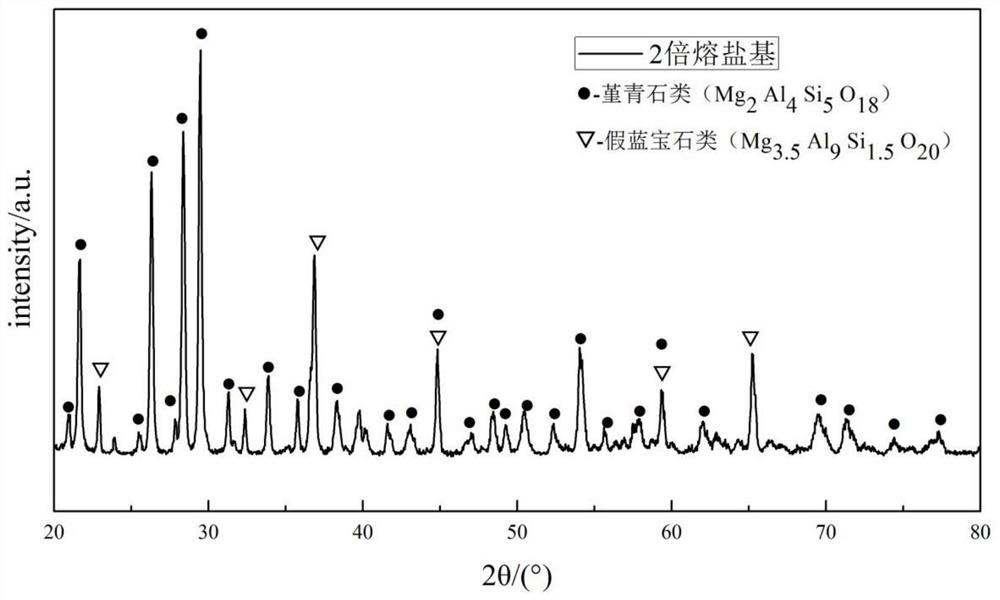

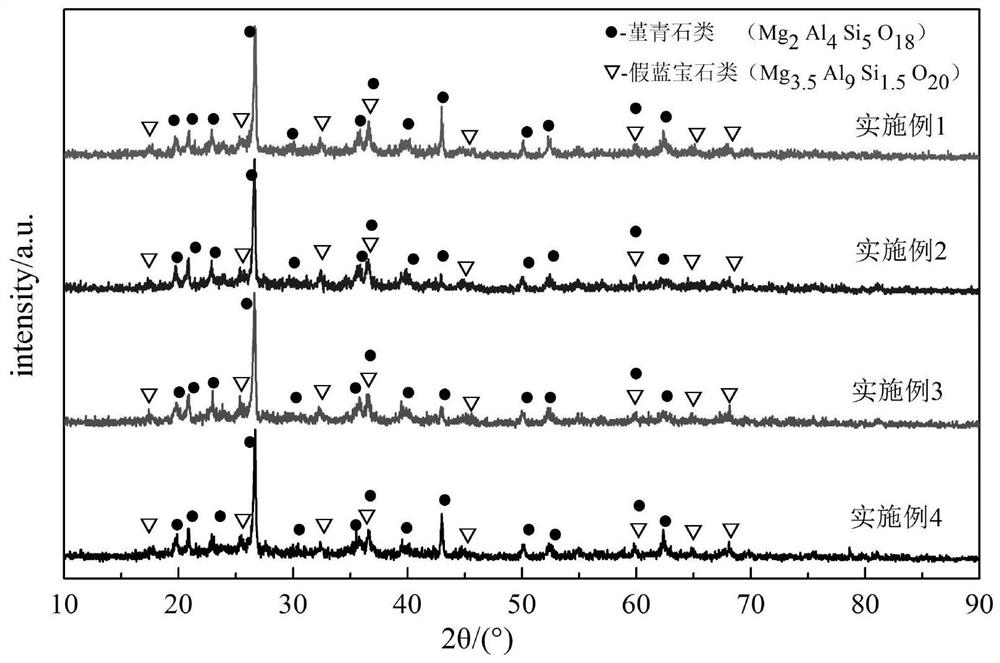

Embodiment 1

[0024] MgO:Al 2 o 3 :SiO2 2 The mol ratio is 2:2:5 as the standard theoretical formula, the quality of the raw material coal gangue and anhydrous magnesium chloride in the present embodiment 1 are respectively 1.1 times and 1.7 times of the quality of the standard theoretical formula, wherein in powder state without Magnesium chloride hydrochloride is used as a molten salt base. Mix the pulverized coal gangue, bauxite, and anhydrous magnesium chloride after grinding to 200 mesh evenly under dry and anhydrous conditions, then calcinate in a box-type resistance furnace at 765°C for 3 hours, and cool to room temperature with the furnace. Then heat and dissolve the calcined product with 80°C deionized water, put it into an 80°C water bath to keep warm, stir, filter, wash for many times, and dry it to obtain cordierite powder.

Embodiment 2

[0026] MgO:Al 2 o 3 :SiO2 2 The mol ratio is 2:2:5 as the standard theoretical formula, the quality of the raw material coal gangue and anhydrous magnesium chloride in the present embodiment 2 are respectively 1.2 times and 1.6 times of the quality of the standard theoretical formula, wherein in powder state without Magnesium chloride hydrochloride is used as a molten salt base. Mix the pulverized coal gangue, bauxite, and anhydrous magnesium chloride after grinding to 200 mesh evenly under dry and anhydrous conditions, then calcinate in a box-type resistance furnace at 765°C for 3 hours, and cool to room temperature with the furnace. Then heat and dissolve the calcined product with 80°C deionized water, put it into an 80°C water bath to keep warm, stir, filter, wash for many times, and dry it to obtain cordierite powder.

Embodiment 3

[0028] MgO:Al 2 o 3 :SiO2 2 The mol ratio is 2:2:5 as the standard theoretical formula, and the quality of the raw material coal gangue and anhydrous magnesium chloride in the present embodiment 3 is respectively 1.1 times and 1.5 times of the quality of the standard theoretical formula consumption, wherein in powder state without Magnesium chloride hydrochloride is used as a molten salt base. Mix the pulverized coal gangue, bauxite, and anhydrous magnesium chloride after grinding to 200 mesh evenly under dry and anhydrous conditions, then calcinate in a box-type resistance furnace at 765°C for 3 hours, and cool to room temperature with the furnace. Then heat and dissolve the calcined product with 80°C deionized water, put it into an 80°C water bath to keep warm, stir, filter, wash for many times, and dry it to obtain cordierite powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com