A kind of preparation technology of tempered glass surface protection coating

A technology for protecting coatings and preparation processes, applied in the direction of coatings, etc., can solve problems such as inferiority, inability to effectively improve impact resistance and prevent breakage, and achieve excellent leveling and impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

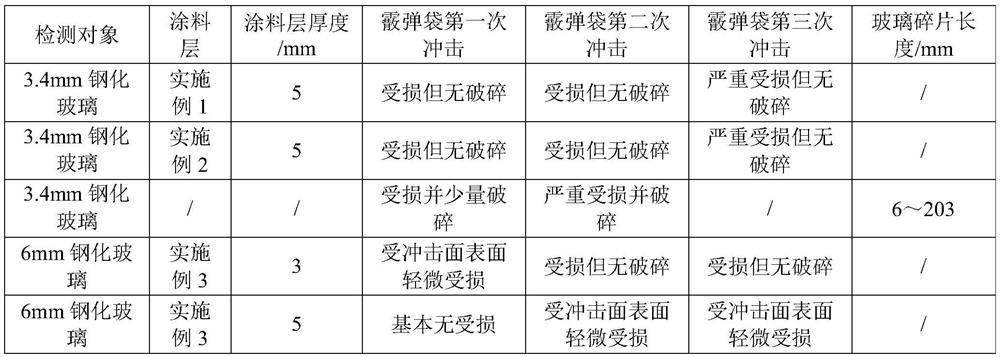

Examples

Embodiment 1

[0033] A preparation process for tempered glass surface protection coating, the preparation process comprises the following preparation steps:

[0034] 1) Pre-preparation of the coating matrix: mix and stir the epoxy resin with an average epoxy value of 41, toluene diisocyanate and isobornyl acrylate at a mass ratio of 11.5:8.3:1.2, and then add epoxy-modified silicone resin and pure methyl methacrylate monomer, continue to stir until fully dissolved to obtain the mixture;

[0035] 2) Preliminary modification: Add porous silica microspheres with a particle size of 5 μm to the mixture obtained in step 1), and add methyltrimethoxysilane after ultrasonic vibration until it is uniformly dispersed, wherein the mixed solution, porous silica The mass ratio of microspheres and methyltrimethoxysilane is 100:3.9:4.15, and the pH value is adjusted to 4.8 with glacial acetic acid, and the acidic mixture is obtained after stirring until uniform, and the acidic mixture is stored at -5°C for...

Embodiment 2

[0039] A preparation process for tempered glass surface protection coating, the preparation process comprises the following preparation steps:

[0040] 1) Pre-preparation of the coating matrix: mix and stir the epoxy resin with an average epoxy value of 53, isophorone diisocyanate and tripropylene glycol diacrylate in a mass ratio of 16.5:17.5:2.7, and add Epoxy-modified silicone resin and pure methyl methacrylate monomer, continue to stir until fully dissolved to obtain a mixture;

[0041] 2) Preliminary modification: Add porous silica microspheres with a particle size of 300 μm to the mixture obtained in step 1), and add methyltrimethoxysilane after ultrasonic vibration until it is uniformly dispersed, wherein the mixed solution, porous silica The mass ratio of microspheres and methyltrimethoxysilane is 100:4.7:5.2, and the pH value is adjusted to 6.1 with dilute hydrochloric acid, and the acid mixture is obtained after stirring until uniform, and the acid mixture is stored ...

Embodiment 3

[0045] A preparation process for tempered glass surface protection coating, the preparation process comprises the following preparation steps:

[0046] 1) Pre-preparation of the coating matrix: mix and stir the epoxy resin with an average epoxy value of 44, dibasic methane diisocyanate and hexanediol diacrylate in a mass ratio of 12.5:9.7:2.35, and add cyclo Oxygen-modified silicone resin and pure methyl methacrylate monomer, continue to stir until fully dissolved to obtain a mixture;

[0047] 2) Preliminary modification: Add porous silica microspheres with a particle size of 60 μm to the mixture obtained in step 1), and add methyltrimethoxysilane after ultrasonic vibration until it is uniformly dispersed, wherein the mixed solution, porous silica The mass ratio of microspheres and methyltrimethoxysilane is 100:4.1:4.65, and the pH value is adjusted to 5.6 with dilute hydrochloric acid, and the acidic mixture is obtained after stirring until uniform, and the acidic mixture is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com