Method for embedding precious metal nanoparticles into rare earth doped luminescent material

A rare earth doped and luminescent material technology, applied in the field of rare earth ion doped inorganic luminescent material preparation, can solve problems such as low fluorescence radiation regulation efficiency, and achieve the effects of enhancing regulation efficiency, increasing fluorescence emission performance, and improving crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

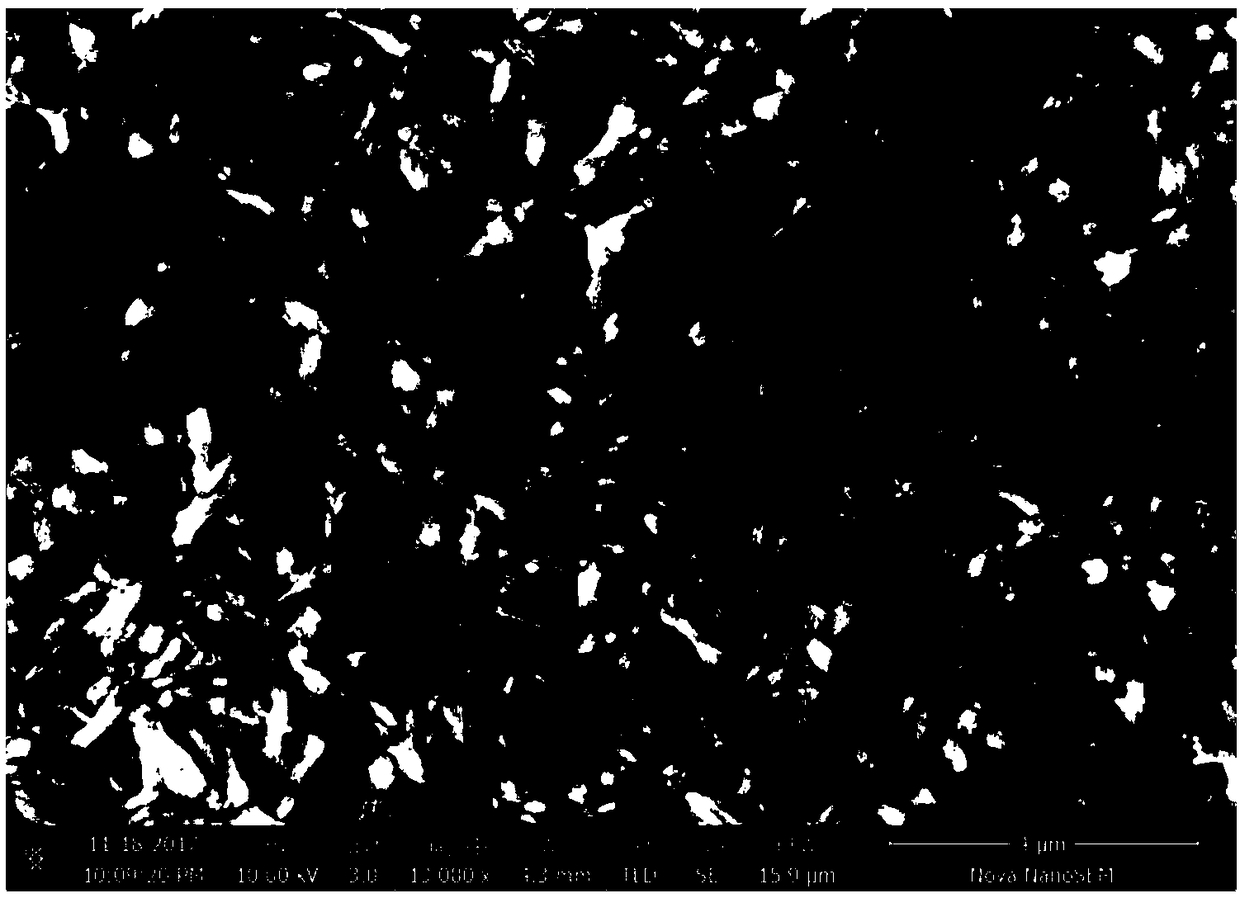

[0035] 1. Au nanoparticles coated YF 3 :Eu 3+ submicron crystals

[0036] Add 0.95mL 0.5mmol / L Y(NO 3 ) 3 aqueous solution and 0.05mL 0.5mmol / LEu(NO 3 ) 3 Aqueous solution, 3mL 0.5mmol / L NaF aqueous solution, in 75°C environment, constant temperature reaction for 2 hours, natural cooling, sequential washing with deionized water and absolute ethanol, and drying at 60°C for 10 hours to obtain YF 3 :Eu 3+ submicron crystals. 0.03g (0.2mmol) YF 3 :Eu 3+ Submicron crystals were added to 40 mL of deionized water, and 1.4 g (7.2 mmol) of trisodium citrate was added. After ultrasonication at room temperature for 10 minutes, the temperature was raised to 70°C, and 30 μL (0.167 mmol) of 3-aminopropyltrimethoxysiloxane was added. , continue to heat up to 90°C, then add 3mL of 0.01mol / L chloroauric acid aqueous solution, react at constant temperature for 15 minutes, cool naturally, sequentially wash with deionized water and absolute ethanol, and dry at 60°C for 10 hours to obtain...

Embodiment 2

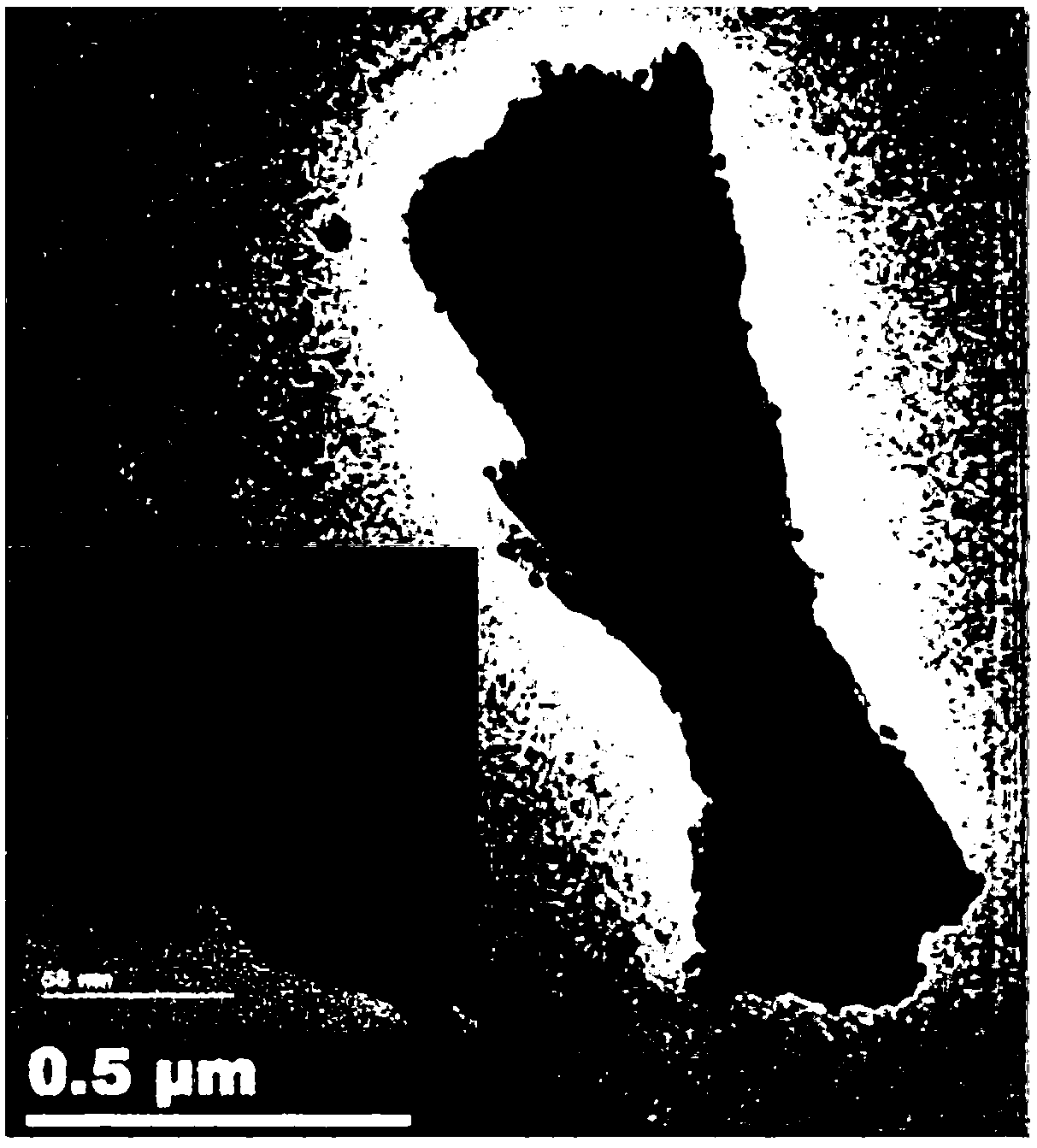

[0040] In this example, the YF 3 :Eu 3+ @Au submicron crystals are irradiated with laser for 5 seconds, the laser wavelength is 532nm (coupled with the wavelength of the Au nanoparticle plasmon resonance peak), and the laser power density is 2×10 3 W / cm 2 , other steps are identical with embodiment 1. Depend on Figure 6-8 It can be seen that some Au nanoparticles are embedded in YF 3 :Eu 3+ Inside the submicron particles, the embedded parts of the Au nanoparticles are circled (see Figure 8 ), and the particle size of Au nanoparticles increases to 20-80nm.

Embodiment 3

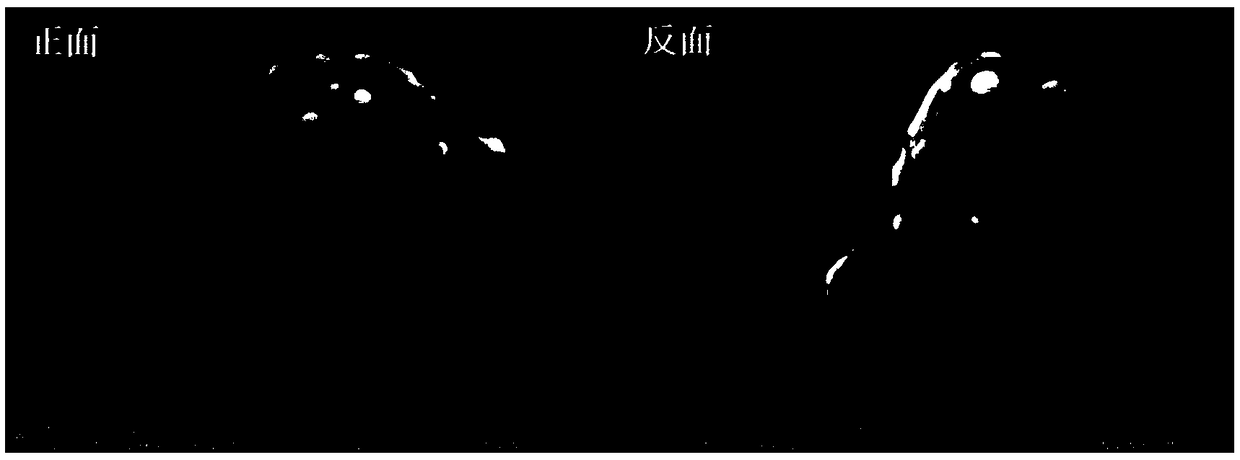

[0042] 1. Au nanoparticles coated NaYF 4 :Eu 3+ submicron crystals

[0043] Add 0.95mL 0.5mmol / L Y(NO 3 ) 3 aqueous solution and 0.05mL 0.5mmol / LEu(NO 3 ) 3 Aqueous solution, 7mL 0.5mmol / L NaF aqueous solution, stirred at room temperature for 60 minutes, heated up to 75°C, reacted at constant temperature for 2 hours, cooled naturally, washed with deionized water and absolute ethanol successively, dried at 60°C for 10 hours, and obtained NaYF 4 :Eu 3+ submicron crystals. 0.03g (0.16mmol) NaYF 4 :Eu 3+ Submicron crystals were added to 40 mL of deionized water, and 1.4 g (7.28 mmol) of trisodium citrate was added. After ultrasonication at room temperature for 10 minutes, the temperature was raised to 70°C, and 30 μL (0.167 mmol) of 3-aminopropyltrimethoxysiloxane was added. , continue to heat up to 90°C, then add 3mL of 0.01mol / L chloroauric acid aqueous solution, react at constant temperature for 15 minutes, cool naturally, successively wash with deionized water and abs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com