Heteropoly acid modified carbon nano tube and/or graphene reinforced lead-based composite anode preparation method

A graphene composite and carbon nanotube technology, applied in chemical instruments and methods, carbon compounds, electrodes, etc., can solve problems such as limited service life, high cost, and insufficient mechanical properties, and achieve low environmental impact, low cost, and prevent easy reunion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

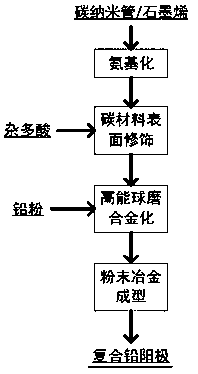

[0027] Such as figure 1 As shown, the carbon nanotubes modified by the heteropolyacid enhances the preparation method of the lead-based composite anode, and its specific steps are as follows:

[0028] Step 1, amination modification treatment: subjecting carbon nanotubes to amination modification treatment;

[0029] Step 1.1, Carboxylation: oxidize the multi-walled carbon nanotubes in a mixed solution of sulfuric acid (98wt%) and nitric acid (68wt%) at a volume ratio of 3:1 at a temperature of 60°C for 4 hours, then filter and deionize Washing with water until neutral, drying in vacuum at 50°C to obtain carboxylated multi-walled carbon nanotubes;

[0030] Step 1.2, acid chlorination: Add 1 g of the carboxylated multi-walled carbon nanotubes obtained in step 1.1 to 20 mL of thionyl chloride, stir and reflux at 70°C for 24 hours, filter and wash with tetrahydrofuran, and dry under vacuum at 50°C to obtain polyacyl chloride walled carbon nanotubes;

[0031] Step 1.3, Amidation...

Embodiment 2

[0039] Such as figure 1 Shown, the graphene reinforced lead-based composite anode preparation method of this heteropolyacid modification, its specific steps are as follows:

[0040] Step 1, amination modification treatment: subjecting graphene to amination modification treatment;

[0041] Step 1.1, carboxylation: oxidize graphene in a mixed solution of sulfuric acid (98wt%) and nitric acid (68wt%) with a volume ratio of 3:1 at a temperature of 60°C for 4 hours, then filter and wash with deionized water until Neutral, vacuum dried at 50°C to obtain carboxylated graphene;

[0042] Step 1.2, acyl chloride: 1 g of the carboxylated graphene obtained in step 1.1 was added to 20 mL of thionyl chloride, stirred and refluxed at 70° C. for 24 hours, filtered, washed with tetrahydrofuran, and vacuum-dried at 50° C. to obtain graphene acyl chloride;

[0043] Step 1.3, amidation: Add 1 g of the acyl chloride graphene obtained in step 1.2, add 5 g of ammonium carbonate, dropwise add 50 m...

Embodiment 3

[0049] Such as figure 1 Shown, this heteropolyacid modified carbon nanotube and graphene reinforced lead-based composite anode preparation method, its specific steps are as follows:

[0050] Step 1, amination modification treatment: subjecting carbon nanotubes and graphene to amination modification treatment;

[0051] Step 1.1, carboxylation: put carbon nanotubes and graphene mixed particles with a mass ratio of 1:1 in a mixed solution of sulfuric acid (98wt%) and nitric acid (68wt%) with a volume ratio of 3:1, at a temperature of 60 ℃ oxidation for 4 hours, then filter, wash with deionized water until neutral, and vacuum dry at 50 ℃ to obtain carboxylated carbon nanotubes and graphene;

[0052] Step 1.2, acyl chloride: Add 1 g of the carboxylated carbon nanotubes and graphene obtained in step 1.1 to 20 mL of thionyl chloride, stir and reflux at 70°C for 24 hours, filter and wash with tetrahydrofuran, and dry under vacuum at 50°C to obtain acid chloride carbon nanotubes and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com