Antibacterial modification method of polymer materials

A polymer material and modification technology, applied in the field of antibacterial materials, can solve the problems of biosafety, easy leakage of nano-silver, and inability to form chemical bonds between polymers and nano-silver, so as to avoid biosafety problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

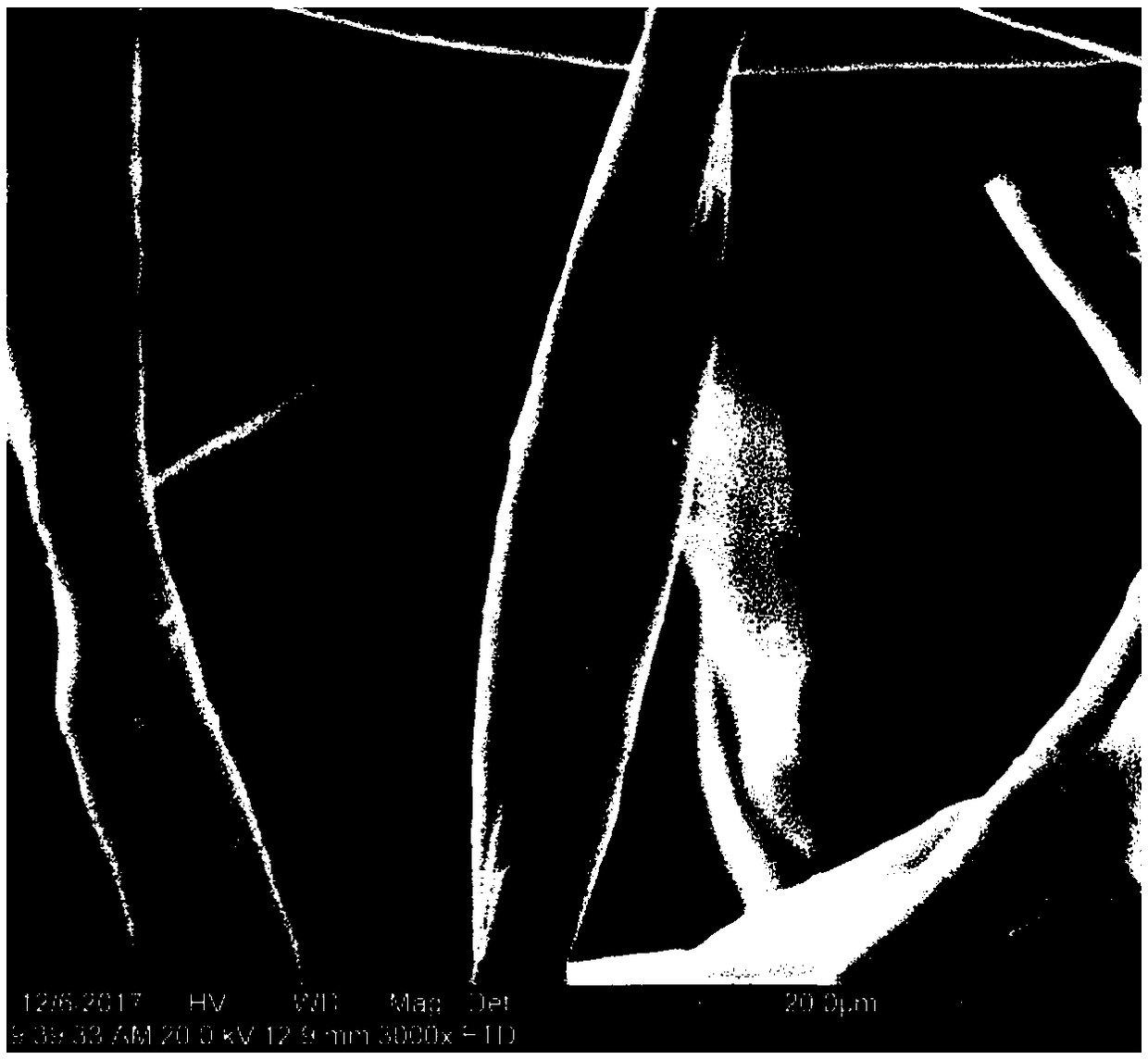

Image

Examples

Embodiment 1

[0061] 1. Synthesis of diazomethane

[0062] (1) Synthesis of compound 1

[0063] Weigh 4.42 g of sulfide anisole and dissolve in 50 mL of dichloromethane, then add 5.00 g of benzoyl chloride dropwise, and stir at room temperature for 24 hours after the dropwise addition. After the reaction, wash with 50 mL of saturated brine three times. The lower organic phase was dried with about 10 g of anhydrous magnesium sulfate, filtered, and rotary evaporated to obtain a crude product. The crude product was dissolved in dichloromethane, and then separated by column chromatography with the ratio of n-hexane:ethyl acetate=4:1 to obtain a pure product (yield 30%).

[0064] (2) Synthesis of compound 2

[0065] Add compound 1 (1g) and 35mL of absolute ethanol into a 100mL round-bottomed flask. After completely dissolving, add 80% hydrazine hydrate (2.19g), then add 2 drops of acetic acid, reflux at 85°C, and the reaction time is 48 hours. After the reaction is complete, perform post-pro...

Embodiment 2

[0076] 1. Synthesis of diazomethane

[0077] With embodiment 1.

[0078] 2. Surface modification of nylon cloth

[0079] Dissolve 0.2g of compound 3 in 5mL of dichloromethane solution, add 2cm×2cm×0.1cm nylon cloth to fully soak the nylon cloth. Then, dichloromethane was removed by rotary evaporation, so that compound 3 was evenly adsorbed on the surface of nylon cloth. Put it into a forced air drying oven and heat it to 120° C. and keep it for 20 minutes. The color of the nylon cloth changed from purple to yellow, indicating that the chemical modification was completed. Finally, wash the nylon cloth with dichloromethane 3 times, 20 mL each time, and dry it in a blast drying oven after washing.

[0080] 3. Preparation of nano-silver solution

[0081] With embodiment 1.

[0082] 4. Preparation of antibacterial nylon cloth

[0083] The silver nanoparticles solution (5 mL) was dissolved in 15 mL of ethylene glycol solution. Then, soak the surface-modified nylon cloth in t...

Embodiment 3

[0085] 1. Synthesis of diazomethane

[0086] With embodiment 1.

[0087] 2. Surface modification of polyurethane

[0088] Dissolve 0.2g of compound 3 in 5mL of cyclohexane solution, add dropwise on the surface of a 2cm×2cm×0.1cm polyurethane film, and blow dry with an ear wash ball while adding, so that compound 3 is evenly adsorbed on the surface of the polyurethane film. Put it into a forced air drying oven and heat it to 120° C. and keep it for 20 minutes. The color of the polyurethane changes from purple to yellow, indicating that the chemical modification is complete. Finally, the polyurethane was washed 3 times with cyclohexane, 20 mL each time, and dried in a blast drying oven after washing.

[0089] 3. Preparation of nano-silver solution

[0090] With embodiment 1.

[0091] 4. Preparation of antibacterial polyurethane film

[0092] The silver nanoparticles solution (5 mL) was dissolved in 15 mL of ethylene glycol solution. Then, soak the surface-modified polyure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com