Anticoagulant textile-based artificial blood vessel material and preparation method thereof

An artificial blood vessel, textile-based technology, applied in the field of artificial blood vessel materials, achieves the effects of low cost, simple process and improved anticoagulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

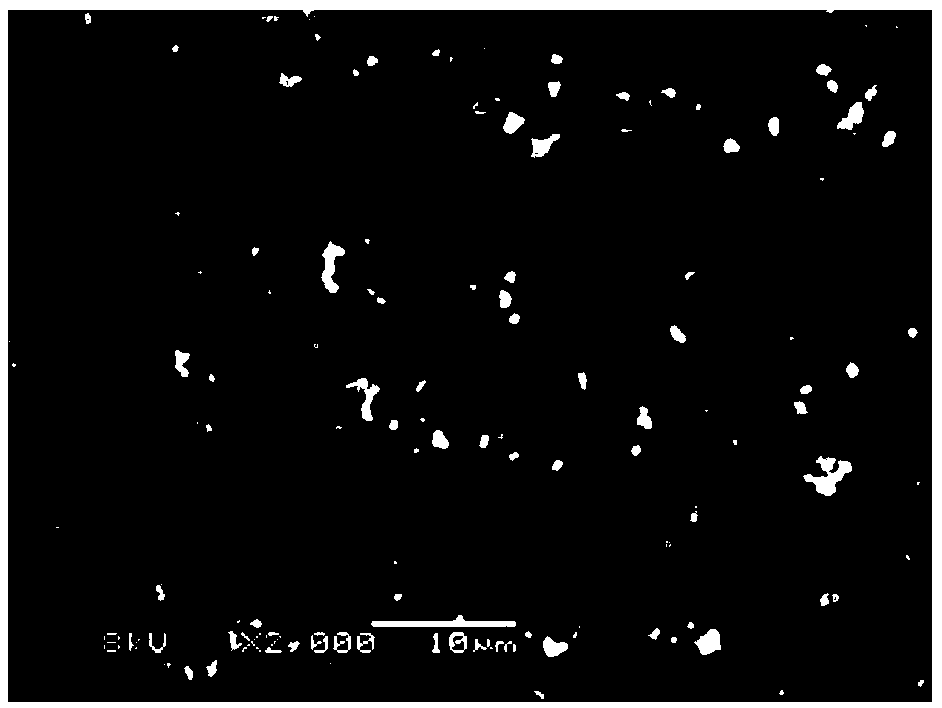

[0038] Remove impurities from a large piece of PET / PTT interwoven fabric sample, dry it, and then cut it into small pieces with a size of 10cm*8cm. Prepare 40g / L NaOH, 1g / L1227 solution, put the fabric sample and the solution into the sample dyeing machine according to the bath ratio of 1:50, treat at 90°C for 20min, then take out the fabric sample, rinse it and dry it .

[0039]Polymerize in a mixed solution of ethanol and water. According to the bath ratio, calculate the volume of the solution required in the polymerization experiment, prepare the solution with the volume ratio of ethanol and water as 2:8, pour it into a beaker, and then add pyrrole, the concentration of pyrrole is 0.6mol / L, stir After uniformity, cool down to 0-5°C, put the treated fabric sample into a beaker, add 20ml of FeCl3 solution at the same time, the concentration is 0.3mol / L, and react at 0-5°C for 4 hours. After the reaction is finished, take out the fabric, rinse it, and put it into an oven for...

Embodiment 2

[0041] Remove impurities from a large piece of PET / PTT interwoven fabric sample, dry it, and then cut it into small pieces with a size of 10cm*8cm. Prepare 40g / L NaOH, 1g / L1227 solution, put the fabric sample and the solution into the sample dyeing machine according to the bath ratio of 1:50, treat at 90°C for 20min, then take out the fabric sample, rinse it and dry it .

[0042] Polymerization in a mixed solution of acetonitrile and water. According to the bath ratio, calculate the volume of the solution required in the polymerization experiment, prepare the solution with the volume ratio of acetonitrile and water as 1:9, pour it into a beaker, then add pyrrole, the concentration of pyrrole is 0.6mol / L, stir After uniformity, cool down to 0-5°C, put the fabric sample into a beaker, weigh 10g of ammonium persulfate (APS), dissolve it with 25ml of water, pour it into the beaker, stir evenly, and react at 0-5°C for 4 hours . After the reaction is finished, take out the fabric...

Embodiment 3

[0044] Remove impurities from a large piece of PET / PTT interwoven fabric sample, dry it, and then cut it into small pieces with a size of 10cm*8cm. Prepare 40g / L NaOH, 1g / L1227 solution, put the fabric sample and the solution into the sample dyeing machine according to the bath ratio of 1:50, treat at 90°C for 20min, then take out the fabric sample, rinse it and dry it .

[0045] Polymerization was performed in a cetyltrimethylammonium bromide (CTAB) template. Calculate the volume of the required solution according to the bath ratio, first determine that the molar ratio of CTAB and pyrrole is 1:2, take 11g CTAB and dissolve it in 200ml of distilled water, pour it into a beaker, then add 4.2ml of Py (pyrrole), After stirring evenly, cool down to 0-5°C, weigh 20g of APS and dissolve it with 25ml of distilled water, put the fabric sample into a beaker, then pour APS into the beaker and stir evenly, react at 0-5°C for 4 hours, and the reaction is over Finally, take out the fabri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com