Combined pump with simple structure and easy installation

A simple structure combined pump technology, applied in the field of combined pumps, can solve the problems of complex processing, large volume, and limited loading capacity of getter pumps, and achieve the effects of reduced leakage rate, compact structure, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

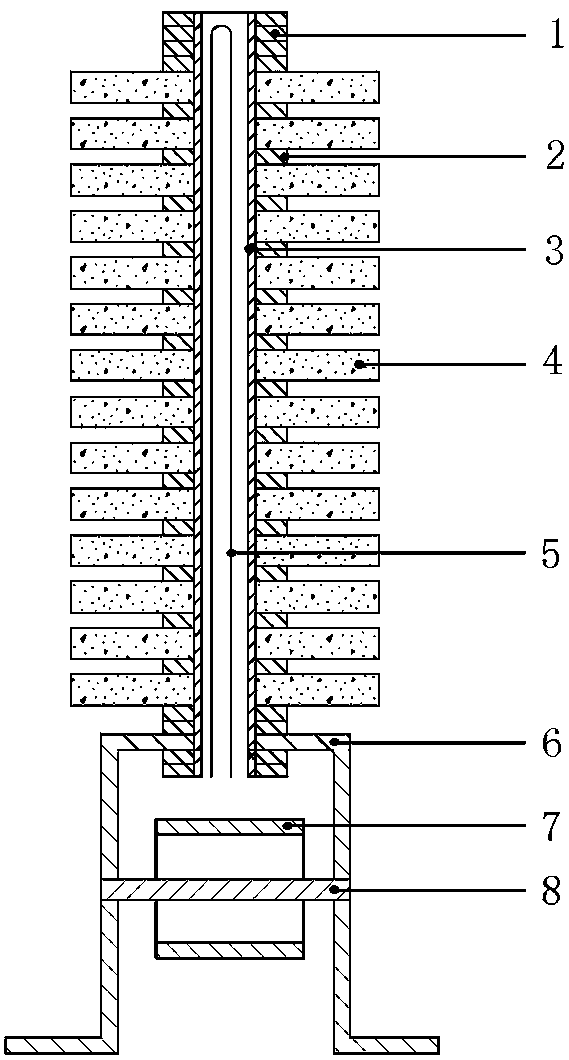

[0033] figure 1 It is a schematic diagram of Embodiment 1 of the present invention. After uniformly mixing 40% by weight of zirconium powder and 60% by weight of zirconium-vanadium-iron alloy powder, press it into a disc with an inner diameter of 6 mm, an outer diameter of 25 mm, and a height of 1.5 mm. These discs are sintered firmly in a vacuum furnace to obtain a porous getter material (4 in the figure). These getter materials are fixed on a heating element consisting of a metal tube (3 in the picture) and a tungsten wire with a diameter of 0.4mm (5 in the picture) coated with an insulating layer through a metal gasket (2 in the picture). , and fix it on a "ji"-shaped base (6 in the picture) made of pure titanium plate with a thickness of 1mm through nuts (1 in the picture). Weld a 316L stainless steel sheet with a thickness of 0.25mm into a single-chamber anode cylinder with a diameter of 25mm and a height of 20mm (7 in the figure), and put it into the cavity at the lowe...

Embodiment 2

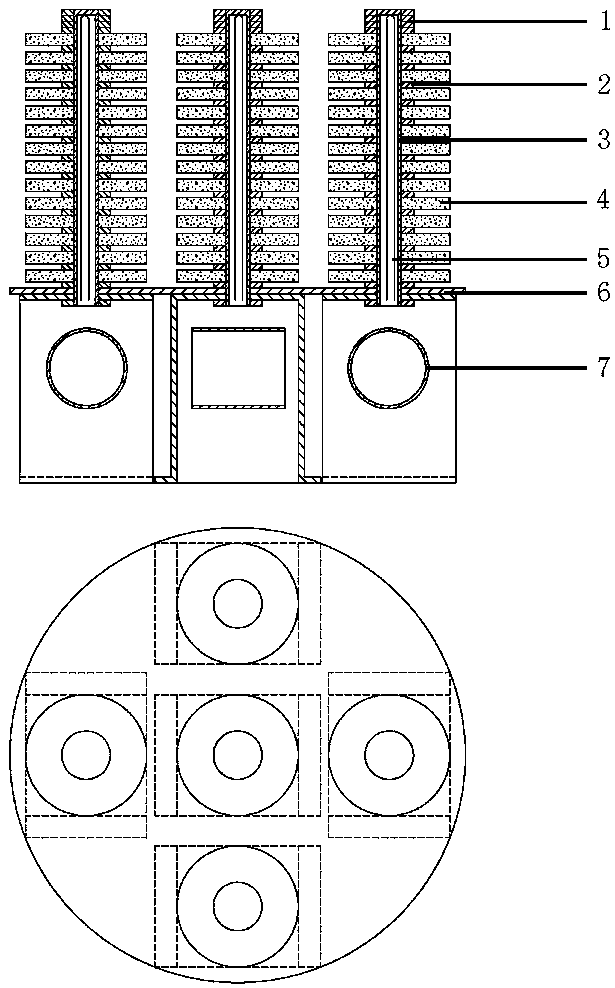

[0036] figure 2 It is a schematic diagram of Embodiment 2 of the present invention. This example is a combined pump with greater pumping speed, which is composed of 5 sets of combined pumps similar to Example 1. The difference from Example 1 is that the base for fixing the getter pump is slightly complicated and there is no Example 1 Titanium rod for enhanced sputtering action.

[0037] Similarly, this combination pump can be installed on the electrode flange first and then connected to the vacuum chamber, or it can be installed inside the vacuum chamber for use. Similarly, to make the combination pump work normally, it is necessary to connect and fix the anode cylinder to the anode of the high-voltage power supply, and connect the tungsten wire in the heating element to the DC or AC power supply, and at the same time, it needs to be parallel to each other on the "several"-shaped base. A set of mutually attracting magnets is installed on a flat surface.

Embodiment 3

[0039] A combination pump with simple structure and easy installation, which is composed of ion pump and getter pump, including metal gasket or ceramic gasket 2, metal tube or ceramic tube 3, multi-piece porous getter material 4, heating wire 5 , a base 6, an anode cylinder 7 and a group of magnets, the base 6 is used as the cathode of the sputtering ion pump; wherein, the multi-sheet porous getter material 4 is separated by a metal gasket 2 and fixed on a metal tube 3 and a tungsten wire 5. On the heating element, the heating element is fixed on the base 6 through the nut 1, and the porous getter material 4 and the heating element form a getter pump; the anode cylinder 7 is arranged in the cavity at the bottom of the base 6, and a group of magnets are installed on the base respectively. Attract each other on parallel planes.

[0040] The porous getter material 4 is made of one or more of titanium, zirconium, hafnium, tantalum, yttrium, niobium, molybdenum, vanadium, manganese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com