bii with different hole transport layers 3 Solar cell and its preparation method

A technology of hole transport layer and solar cell, which is applied in semiconductor/solid-state device manufacturing, circuit, photovoltaic power generation, etc. It can solve the problems of device performance degradation, threats to the ecological environment and human health, and the preparation process is not simple enough to achieve good stability. high reliability, low preparation cost and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] BiI with different hole transport layers 3A method for preparing a solar cell, comprising the steps of:

[0073] (1), prepare a transparent conductive metal oxide cathode layer on the substrate:

[0074] Sputtering metal oxide on the substrate to prepare a transparent conductive metal oxide cathode layer;

[0075] (2) Preparation of dense TiO on the transparent conductive metal oxide cathode layer 2 Electron transport layer:

[0076] Using the spraying method, dilute 1mL of 75wt% titanium diisopropoxybisacetylacetonate in isopropanol with 9mL of absolute ethanol, spray evenly on the transparent conductive metal oxide cathode layer, and then sinter to obtain dense TiO 2 Electron transport layer;

[0077] (3), in dense TiO 2 Preparation of BiI on electron transport layer 3 layer:

[0078] BiI in the glove box 3 solution and Li-TFSI doped BiI 3 solution spin coating on dense TiO 2 on the electron transport layer, and then annealed to obtain BiI 3 Layer, that is,...

Embodiment 1

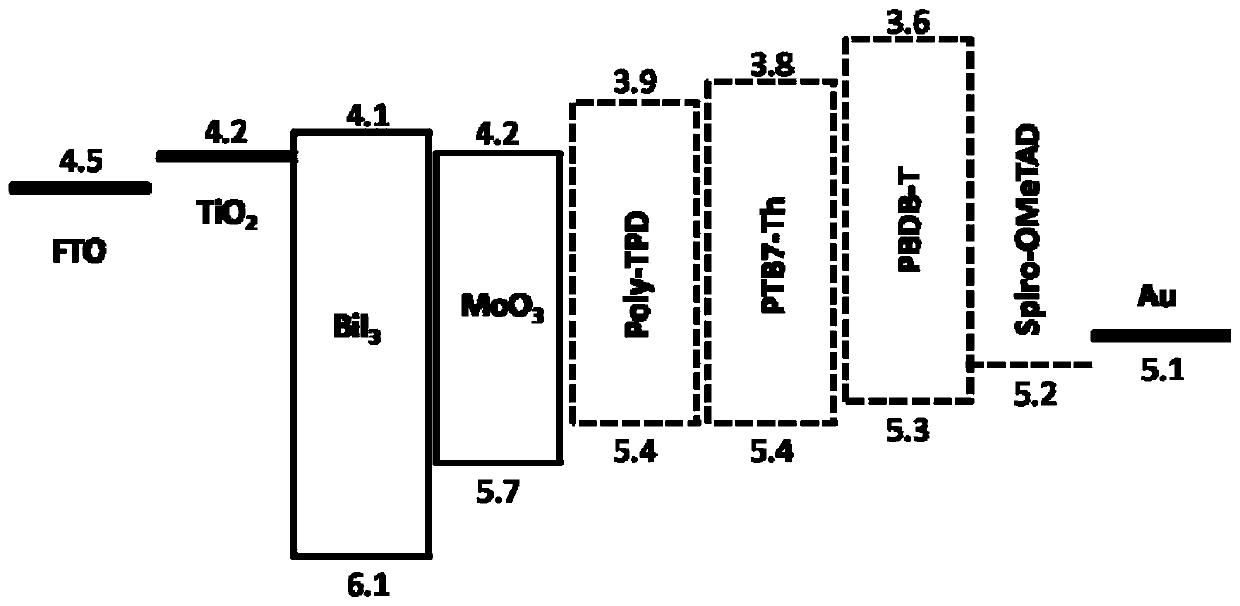

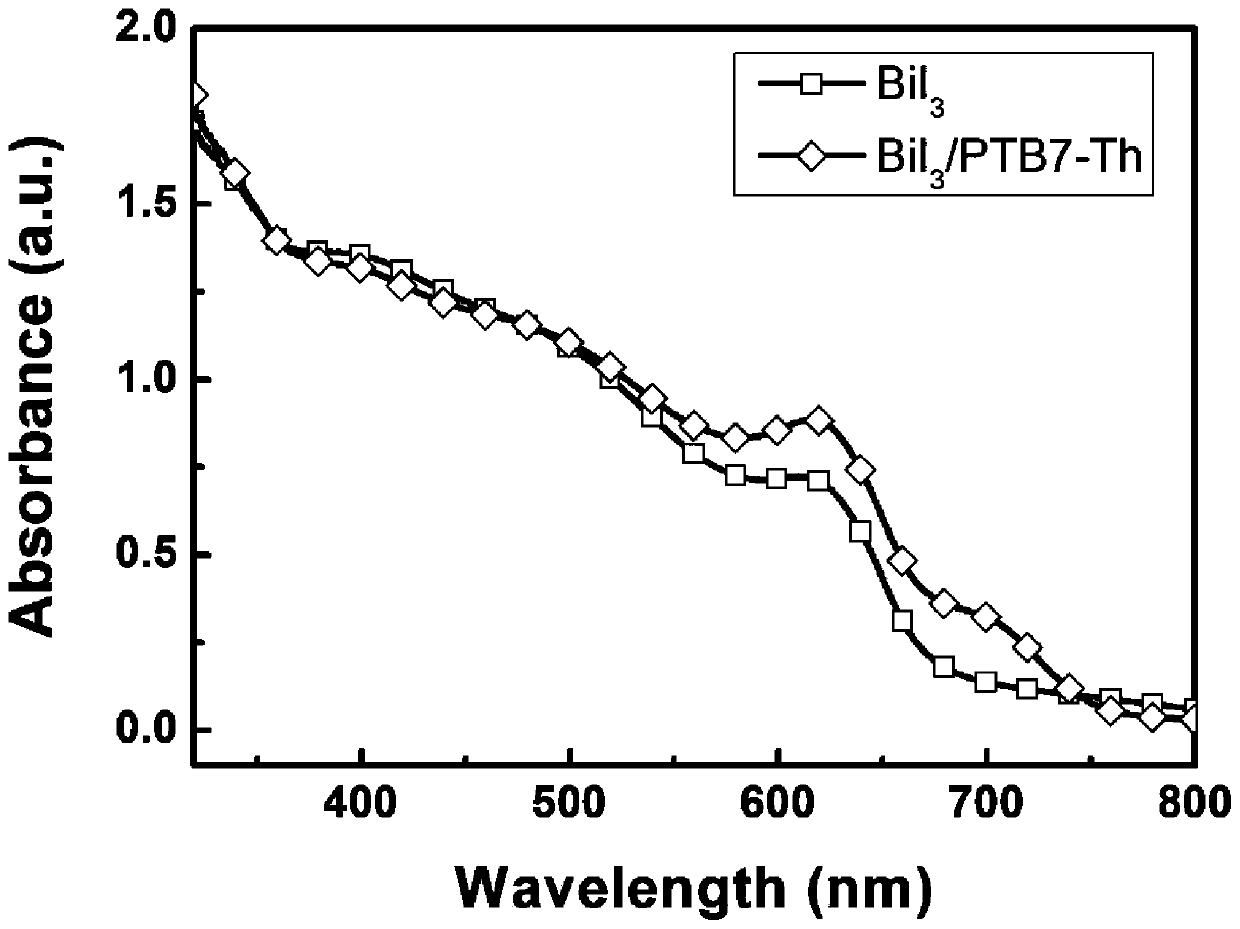

[0096] Embodiment 1 (PTB7-Th, do comparative example)

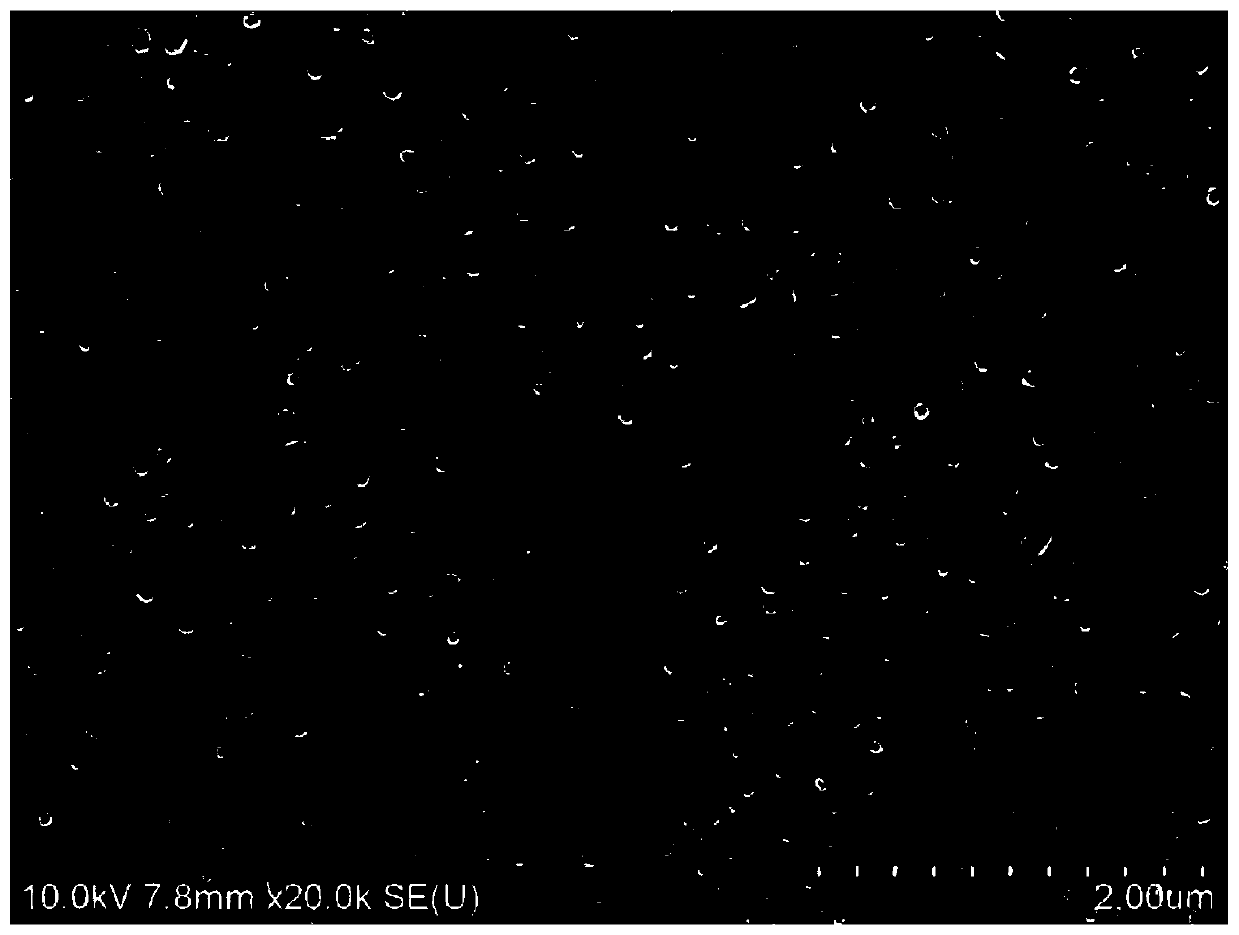

[0097] will be sputtered with fluorine-doped SnO 2 (FTO) transparent conductive glass was ultrasonically cleaned twice with detergent, tap water, deionized water, acetone, and isopropanol, each time for 15 minutes, dried with nitrogen, placed on a flat furnace, and placed on the FTO substrate with a glass sheet The position of the electrode is shielded, the temperature is raised to 450°C, and then the ethanol solution of diisopropoxybisacetylacetonate titanium is sprayed at 450°C, thermally annealed at 450°C for 30 minutes in the air, and then naturally cooled to obtain dense TiO 2 electron transport layer. BiI 3 The solid particles were fully dissolved in DMF (N,N-dimethylformamide) at a concentration of 200 mg / ml to obtain a precursor solution, which was filtered with a filter head with a diameter of 22 μm. in N 2 In the glove box, the precursor solution was spin-coated on the dense TiO with an acceleration of 1500r...

Embodiment 2

[0098] Example 2 (Poly-TPD)

[0099] will be sputtered with fluorine-doped SnO 2 (FTO) transparent conductive glass was ultrasonically cleaned twice with detergent, tap water, deionized water, acetone, and isopropanol, each time for 15 minutes, dried with nitrogen, placed on a flat furnace, and placed on the FTO substrate with a glass sheet The position of the electrode is shielded, the temperature is raised to 450°C, and then the ethanol solution of diisopropoxybisacetylacetonate titanium is sprayed at 450°C, thermally annealed at 450°C for 30 minutes in the air, and then naturally cooled to obtain dense TiO 2 electron transport layer. BiI 3 The solid particles were fully dissolved in DMF (N,N-dimethylformamide) at a concentration of 200 mg / ml to obtain a precursor solution, which was filtered with a filter head with a diameter of 22 μm. in N 2 In the glove box, the precursor solution was spin-coated on the dense TiO with an acceleration of 1500rpm / s at a speed of 3000rpm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com