Production method of rose flower jam

A technology of rose sauce and production method, which is applied to the functions of food ingredients, food science, food preservation, etc. It can solve the problems of great damage to the color and aroma of roses, easy crystallization of sucrose, and reduced activity of anthocyanins. Achieve the effect of color and fragrance retention, fine and smooth taste, and improvement of delicateness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

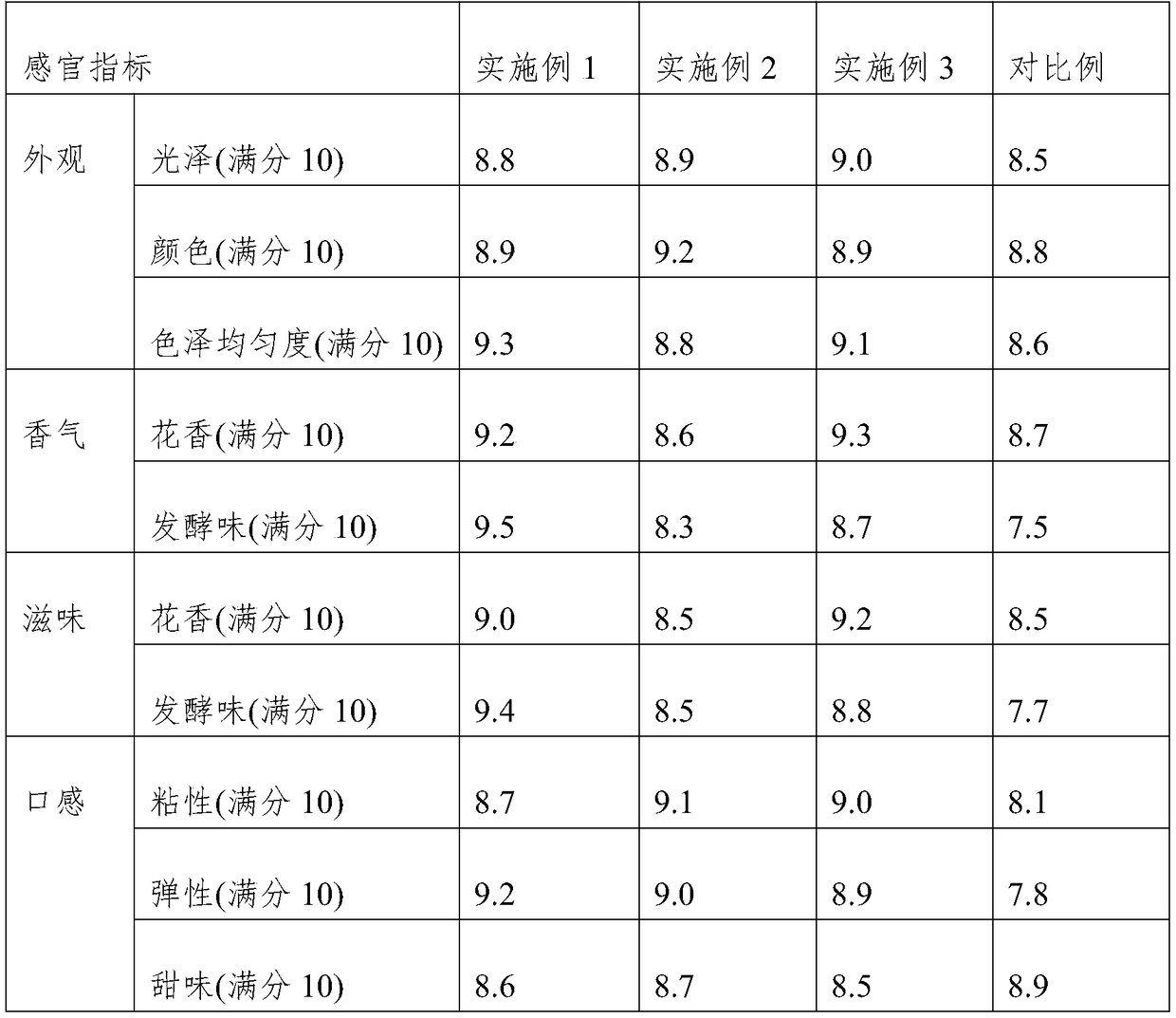

Examples

Embodiment 1

[0031] Present embodiment provides a kind of production method of rose jam, comprises the following steps:

[0032] A: Mix the bark and tangerine peel, add 10 times of water, simmer for 35 minutes, filter to obtain the peel liquid;

[0033] B: Mix aloe vera, okra, and bracken to make a pulp, filter, put the obtained slurry in a pot, boil it with a slow fire to make a paste, and set aside;

[0034] C: take rose petals and carry out superfine pulverization after drying with hot air, then add water and vitamin E with 5 times the mass of rose pollen to rose pollen, stir rose pulp, inoculate compound enzyme with 0.6% of rose pulp mass, in 15 Low-temperature enzymatic hydrolysis for 7 hours under the condition of ℃, inoculation of compound fermentation bacteria with 0.9% of the mass of rose pulp, low-temperature fermentation at 15°C for 7 hours, and then adding 5-8% of the mass of preservative to the rose pulp to obtain a fermented type rose syrup;

[0035] D: Take brown sugar and...

Embodiment 2

[0041] Present embodiment provides a kind of production method of rose jam, comprises the following steps:

[0042] A: Mix the bark and tangerine peel, add 8 times the water, simmer for 30 minutes, filter to obtain the peel liquid;

[0043] B: Mix aloe vera, okra, and bracken to make a pulp, filter, put the obtained slurry in a pot, boil it with a slow fire to make a paste, and set aside;

[0044]C: take rose petals and carry out superfine pulverization after hot air drying, then add water and vitamin E with 3 times the mass of rose pollen to rose pollen, stir rose pulp, inoculate compound enzyme with 0.2% of rose pulp mass, in 8 Low-temperature enzymatic hydrolysis for 5 hours under the condition of 5°C, inoculation of compound fermentation bacteria with 0.35% of the mass of rose pulp, low-temperature fermentation at 5°C for 5 hours, and then adding 5% of the mass of preservative to the rose pulp to obtain fermented roses pulp;

[0045] D: Take brown sugar and boil to make ...

Embodiment 3

[0051] Present embodiment provides a kind of production method of rose jam, comprises the following steps:

[0052] A: Mix the bark and tangerine peel, add 9 times of water, simmer for 32 minutes, filter to obtain the peel liquid;

[0053] B: Mix aloe vera, okra, and bracken to make a pulp, filter, put the obtained slurry in a pot, boil it with a slow fire to make a paste, and set aside;

[0054] C: Take rose petals and dry them with hot air, then carry out superfine pulverization, then add water and vitamin E with 4 times the mass of rose pollen to the rose pollen, stir the rose pulp, inoculate the compound enzyme with 0.4% of the mass of rose pulp, in 10 Low-temperature enzymatic hydrolysis for 6 hours under the condition of ℃, inoculation of compound fermentation bacteria with 0.55% of the mass of rose pulp, low-temperature fermentation at 10°C for 6 hours, and then adding 6.5% of the mass of preservative to the rose pulp to obtain fermented roses pulp;

[0055] D: Take b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com