Method and catalyst for extracting 2-octanone from crude 2-octyl alcohol and hydrogenating to prepare 2-octyl alcohol

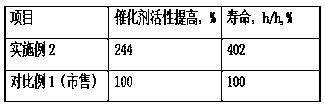

A technology for crude sec-octanol and sec-octone, applied in the field of chemical refining, can solve the problems of low selectivity, long reaction time, complicated methods, etc., and achieve the effects of improving catalyst activity, prolonging service life and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 A kind of catalyst that produces secondary octanol by hydrogenation of secondary octanone

[0025] A catalyst for producing 2-octanol by hydrogenation of 2-octanone of the present invention is composed of activated carbon carrier and composite catalyst powder. The composite catalyst powder consists of 30 parts of diatomite, 15 parts of nickel oxide, 3 parts of zinc aluminate 2 parts, 2 parts of titanium oxide, 3 parts of niobium oxide, 8 parts of diboron trioxide, 11 parts of aluminum oxide, and 8 parts of zirconia.

[0026] The preparation method of described activated carbon carrier, comprises the steps:

[0027] a Selection of carrier materials

[0028] Select high-quality coconut shells as raw materials. The coconut shells are fresh coconut shells of the year, the outer green peel is removed, the long diameter is 5.5cm, the short diameter is 4.2cm, and the moisture content is 7.5%.

[0029] b alkali dipping

[0030] The above-mentioned coconut shells...

Embodiment 2

[0040] Embodiment 2 A kind of preparation method of the catalyst that produces secondary octanol by the hydrogenation of secondary octanone of the present invention comprises the following steps:

[0041] (1) Weigh diatomite, nickel oxide, zinc aluminate, titanium oxide, niobium oxide, boron trioxide, aluminum oxide, and zirconium oxide according to the proportion of the formula, add appropriate amount of deionized water, and grind for 5.5 hours in a colloid mill. Grind through a 200 mesh sieve.

[0042] (2) Weigh diatomite and dissolve it in deionized water, add zinc aluminate, niobium oxide, diboron trioxide, and aluminum oxide and stir to form a paste. After standing at room temperature for 12 hours, transfer to an oven to dry and grind;

[0043] Then it was placed in a tube furnace, and the temperature was raised to 455° C. at a rate of 10° C. / min under a nitrogen flow, and it was calcined for 0.5 h and then lowered to room temperature to obtain a powder.

[0044] (3) Add...

Embodiment 3

[0047] Example 3 A method of extracting secondary octanone and hydrogenating secondary octanol from crude secondary octanol to produce secondary octanol according to the present invention

[0048] Include the following steps:

[0049] A extracts 2-octyl ketone from crude 2-octanol:

[0050]Extract secondary octanone from crude secondary octanol according to the separation and purification method of partition distillation, wherein the pressure in the first chamber of the first distillation tower is 15kPa, the pressure in the second tower chamber is 12kPa, and the gas phase temperature at the top of the tower is 135°C. The pressure of the second distillation column is 20kPa, and the gas phase temperature at the top of the column is 160°C.

[0051] After testing, the extraction rate of secondary octanone in this step is 99.6%, the purity of secondary octanone is 99.2%, and the proportion of secondary octanol in impurities is 97.8%.

[0052] B hydrogenation reaction:

[0053] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com