Preparation method of high-toughness ageing-resistant agricultural plastic mulching film

An agricultural mulch film and anti-aging technology, which is applied in the direction of botanical equipment and methods, application, climate change adaptation, etc., can solve the problems of easy aging and poor mechanical properties of agricultural mulch film, achieve low porosity, improve aging resistance, and toughness Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

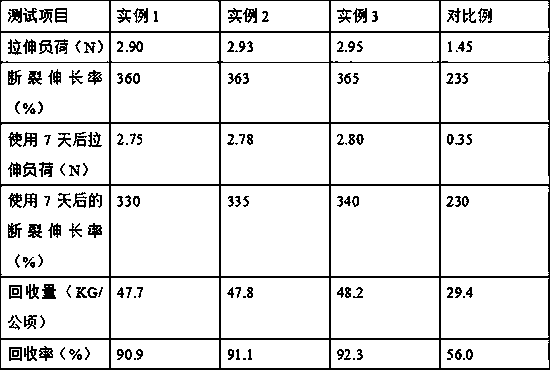

Examples

example 1

[0024] Weigh 500g of straw and put it into a beaker, soak the straw with a 10% sodium hydroxide solution, put the beaker into a water bath with a water bath temperature of 90°C, and react at a constant temperature for 90 minutes, filter to obtain a filter residue, and put the filter residue in a Dry in an oven at a temperature of 60°C for 2 hours. After drying, use a pulverizer to crush through a 300-mesh sieve to obtain dry fibers. Mix the dry fibers and polyvinyl alcohol at a mass ratio of 1:2 to obtain a suspension, and set aside; bagasse Put the sodium hydroxide solution with a mass fraction of 17% into a beaker at a mass ratio of 1:2, mix and stir at a speed of 200r / min for 120min at room temperature, filter to obtain a filter residue, wash with distilled water and absolute ethanol three times in turn, and Put it in an oven and dry it at 105°C for 50 minutes to prepare the reaction pulp; put the above reaction pulp and 25% sodium hydroxide solution into a flask at a mass r...

example 2

[0026]Weigh 600g of straw and put it into a beaker, soak the straw with 12% sodium hydroxide solution by mass fraction, put the beaker into a water bath with a water bath temperature of 92°C and react at a constant temperature for 95min, filter to obtain a filter residue, put the filter residue in Dry in an oven at a temperature of 62°C for 2.5 hours. After drying, use a pulverizer to crush through a 300-mesh sieve to obtain dry fibers. Mix the dry fibers and polyvinyl alcohol at a mass ratio of 1:2 to obtain a suspension, and set aside; sugarcane The slag and the sodium hydroxide solution with a mass fraction of 18% were put into a beaker at a mass ratio of 1:2, mixed and stirred at a speed of 220r / min for 130min at room temperature, filtered to obtain the filter residue, and washed with distilled water and absolute ethanol four times in sequence. And put it in an oven to dry at 107°C for 55 minutes to prepare the reaction pulp; put the above reaction pulp and 27% sodium hydro...

example 3

[0028] Weigh 700g of straw and put it into a beaker, soak the straw with a 15% sodium hydroxide solution, put the beaker into a water bath with a water bath temperature of 95°C, and react at a constant temperature for 100 minutes, filter to obtain a filter residue, and put the filter residue in Dry in an oven at a temperature of 65°C for 3 hours. After drying, use a pulverizer to crush through a 300-mesh sieve to obtain dry fibers. Mix the dry fibers and polyvinyl alcohol at a mass ratio of 1:2 to prepare a suspension for later use; bagasse Put the sodium hydroxide solution with a mass fraction of 19% into a beaker at a mass ratio of 1:2, mix and stir at a speed of 240r / min for 140min at room temperature, filter to obtain a filter residue, wash it with distilled water and absolute ethanol for 5 times, and Put it in an oven and dry it at 110°C for 60 minutes to prepare the reaction pulp; put the above reaction pulp and 30% sodium hydroxide solution in a mass ratio of 1:10 into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com