Method for preparing indium hydroxide

A technology of indium hydroxide and indium flowers, which is applied in the field of preparation of indium hydroxide, can solve the problems of hydrothermal synthesis method growth temperature limitation, difficulty in realizing industrial production, difficulty in controlling process parameters, etc., and achieve high practical value, short cycle, less reunion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

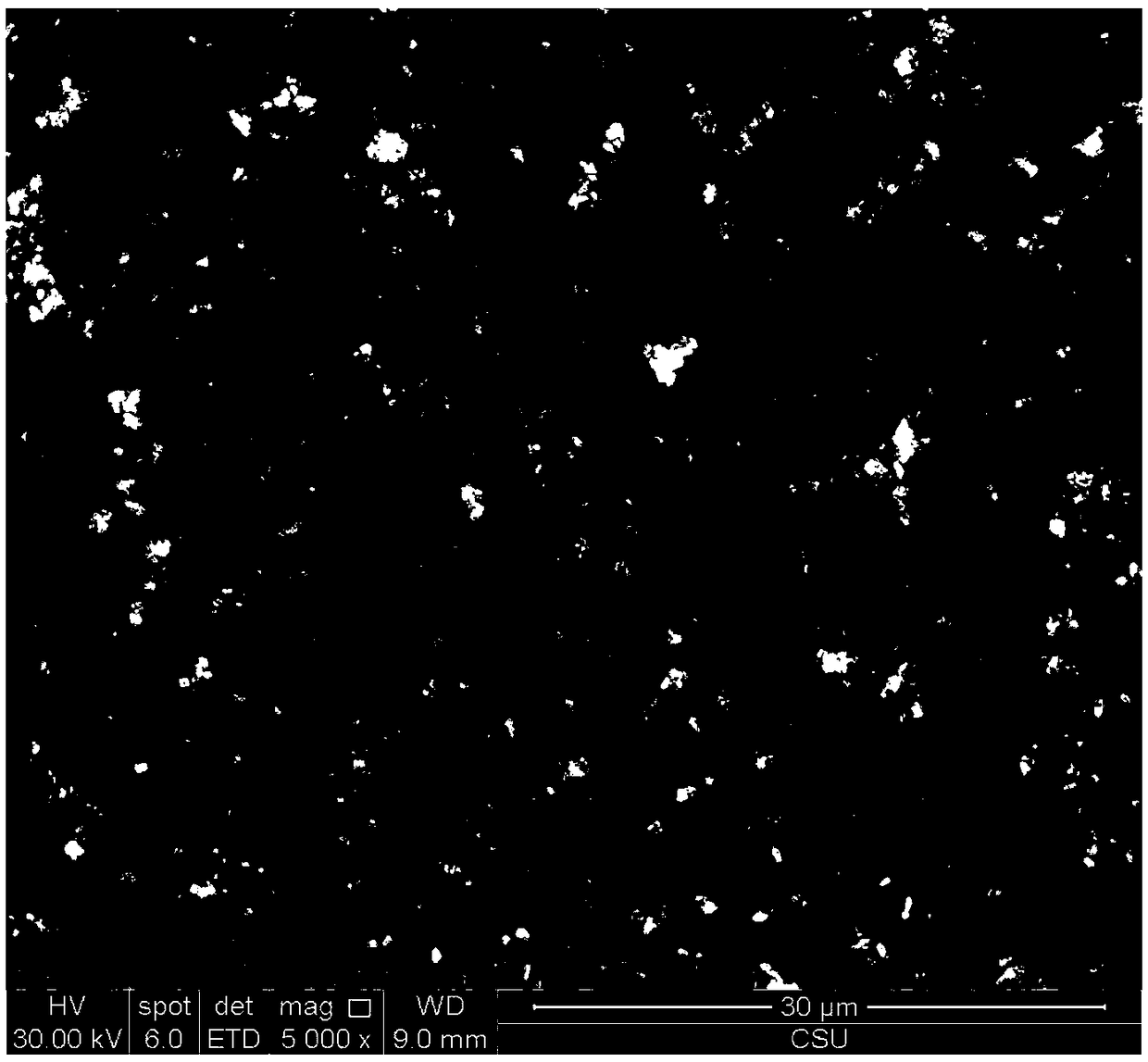

Examples

preparation example Construction

[0029] The present invention proposes a kind of preparation method of indium hydroxide, comprises the following steps:

[0030] S1. Melt the indium ingot at 200-400°C, pour the molten liquid into a container filled with pure water, and spray pure water on the poured molten liquid at the same time to obtain indium flowers, and filter the indium flowers with a screen;

[0031] S2. Dissolving the filtered indium flowers with nitric acid to obtain a mixed solution of indium nitrate, diluting the mixed solution of indium nitrate with water until the molar concentration of indium is 0.1-5.0 mol / L;

[0032] S3, adding a water-soluble acid amine dispersant to the mixed solution, and then adding an alkaline aqueous solution to generate a precipitate to obtain a hydroxide precursor slurry;

[0033] S4, transfer the slurry to the storage tank and wash it with ceramic membrane equipment;

[0034] S5. Spray drying the washed slurry to obtain dried indium hydroxide powder.

[0035] In som...

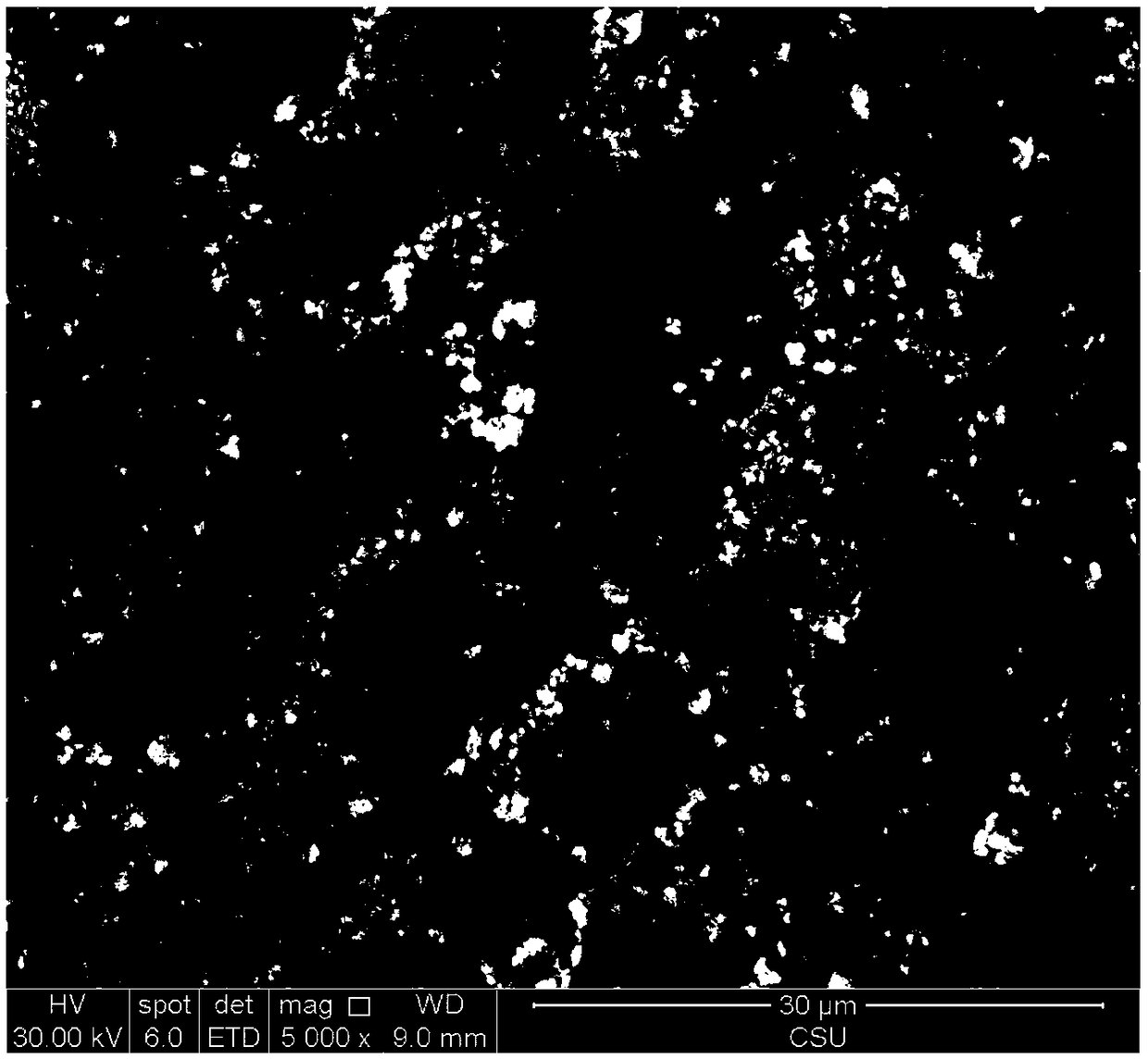

Embodiment 1

[0047]Melt the weighed indium ingot at 200°C, pour the molten liquid into a container filled with pure water, and spray pure water on the poured molten liquid at the same time to obtain indium flowers, and filter the indium flowers with a sieve; Take the indium flower filtered by the sieve, add nitric acid to dissolve it to obtain an indium nitrate solution, dilute the indium nitrate solution with water to make the molar concentration of indium 3.0mol / L, and add polyacrylamine with a theoretical precursor hydroxide mass of 0.5% at the same time , 12wt% ammonia solution was added dropwise at 30 ml / min under stirring at 60°C, the final pH was 11, aged for 12 hours, the slurry was transferred to a storage tank for washing with ceramic membrane equipment, and pure water was added for circular washing until the conductivity The rate is 30.3μs / cm, and the washed slurry is spray-dried by a centrifugal spray dryer. The inlet air temperature of the centrifugal spray dryer is 300°C, and ...

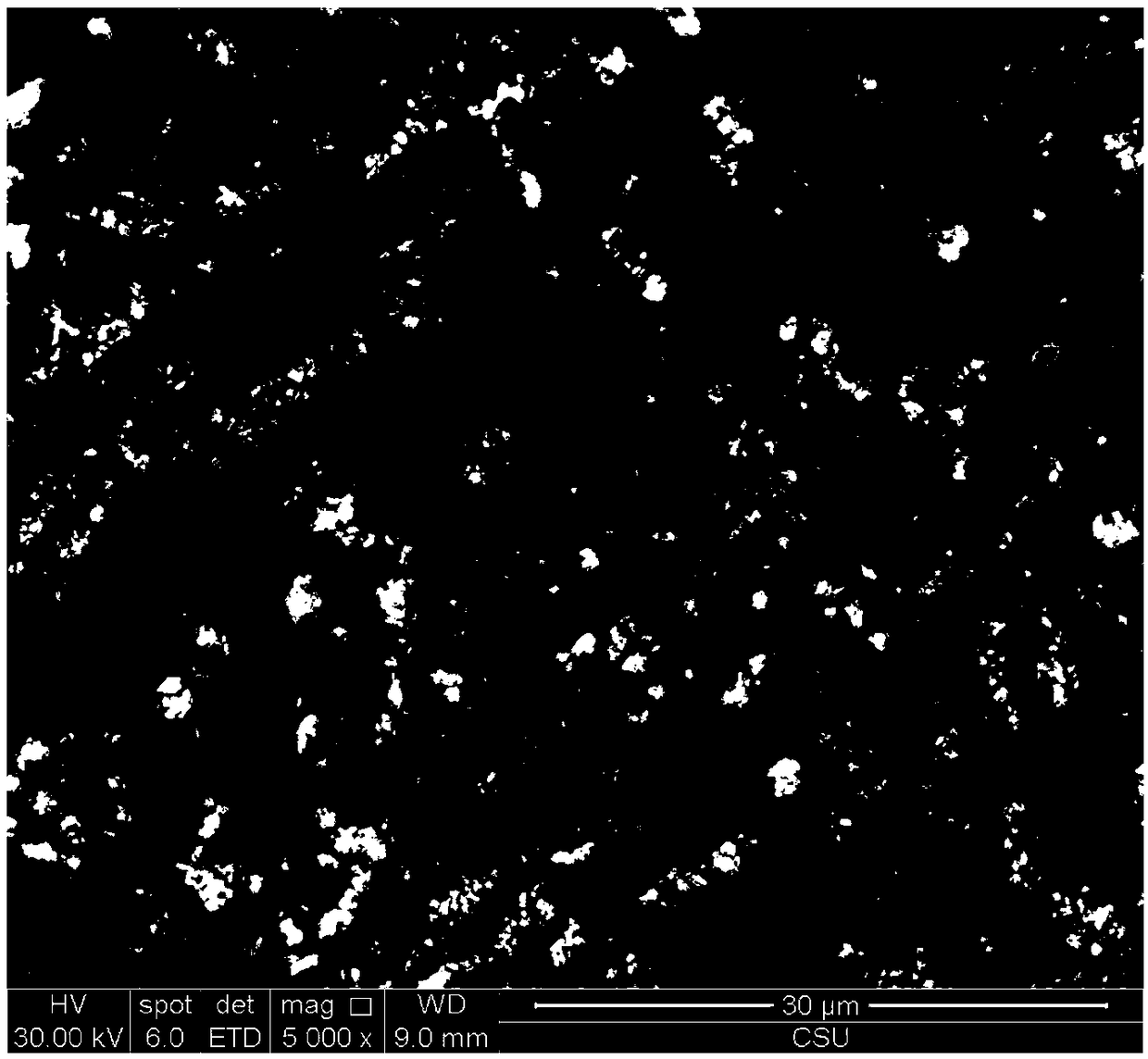

Embodiment 2

[0049] Melt the weighed indium ingot at 300°C, pour the molten liquid into a container filled with pure water, and spray pure water on the poured molten liquid at the same time to obtain indium flowers, and filter the indium flowers with a sieve; Take the indium flowers filtered by the sieve, add nitric acid to dissolve to obtain an indium nitrate solution, dilute the indium nitrate solution with water to make the molar concentration of indium 2.0mol / L, and add polyacrylamine with a theoretical precursor hydroxide mass of 0.5% at the same time , under stirring at 25°C, add 5wt% ammonia solution dropwise at 50 ml / min, the final pH is 8.0, age for 12 hours, transfer the slurry to a storage tank and wash it with a ceramic membrane equipment, add pure water for circular washing, and wash until the conductivity The rate is 8.5μs / cm, and the washed slurry is spray-dried by a centrifugal spray dryer. The inlet air temperature of the centrifugal spray dryer is 250°C, and the outlet air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductance | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com