Preparation method of flame retardant flexible heat-shrinkable tube

A heat-shrinkable sleeve and flexible technology, which is applied in the field of preparation of flame-retardant flexible heat-shrinkable sleeves, can solve the problems of heat-shrinkable materials that do not have flame-retardant properties, poor toughness of heat-shrinkable sleeves, stress cracking, etc. The effect of cracking, increased intercalation distance, and enhanced interfacial bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

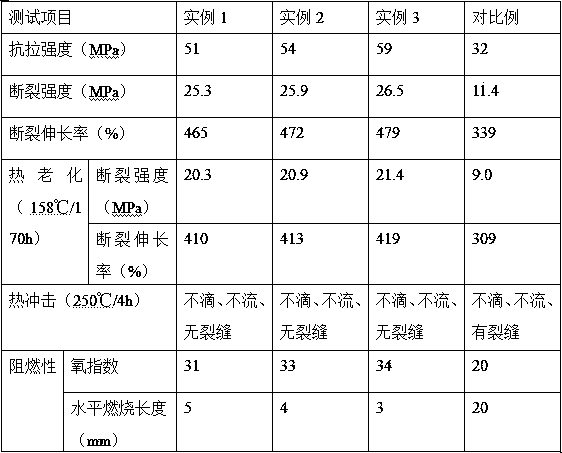

Examples

Embodiment Construction

[0022] Add 600-700mL of ethanol aqueous solution with a mass fraction of 40% into the three-necked flask, transfer the three-necked flask to a water bath, heat up to 70-80°C, add 30-35g of magnesium aluminum hydrotalcite to the three-necked flask, and start Stir and mix with a magnetic stirrer at a speed of 350-400r / min for 1-2 hours to obtain a uniformly dispersed hydrotalcite suspension; put 70-80g potassium monododecyl methyl phosphate into the above-mentioned hydrotalcite suspension, stir Mix for 5-10 minutes, adjust the pH of the hydrotalcite suspension to 4-5 with hydrochloric acid with a mass fraction of 15%, heat up to 80-90°C, stir and react for 6-7 hours to obtain a white slurry, put the white slurry in vacuum filtration After suction filtration in the machine, remove the filtrate and separate to obtain a white filter residue, wash the white filter residue with absolute ethanol, place it in an oven with a set temperature of 90-100°C, and dry it for 7-8 hours to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com