Porous nanofiber membrane for detecting explosive vapor in humid environment and preparation method and application of porous nanofiber membrane

A nanofiber and wet environment technology, applied in the field of fluorescent detection of explosives, can solve the problems of unfavorable electron transfer energy and the inability to detect nitro explosives, etc., and achieve the effects of rapid mass production, adjustable fiber diameter, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

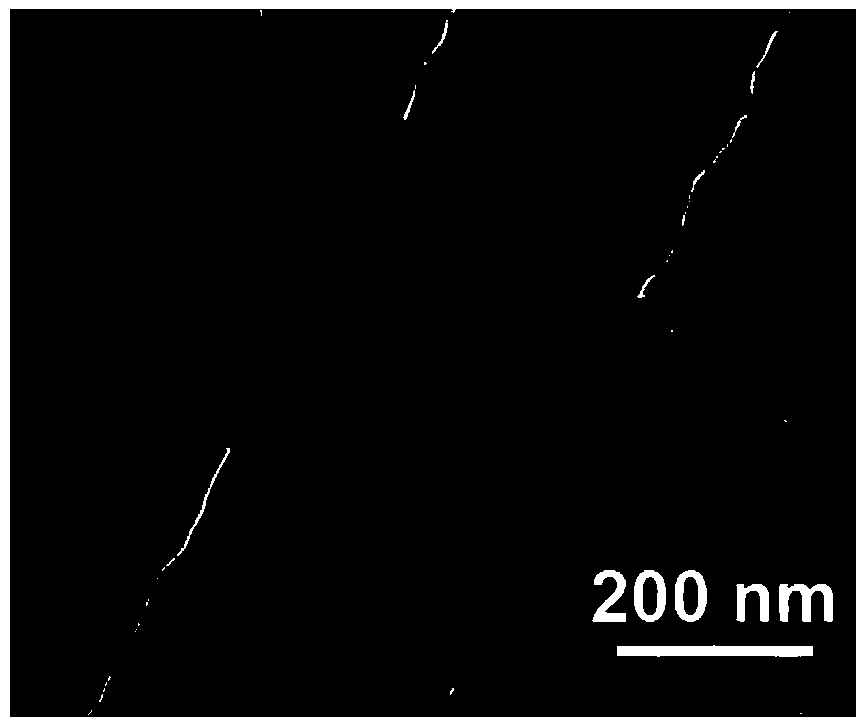

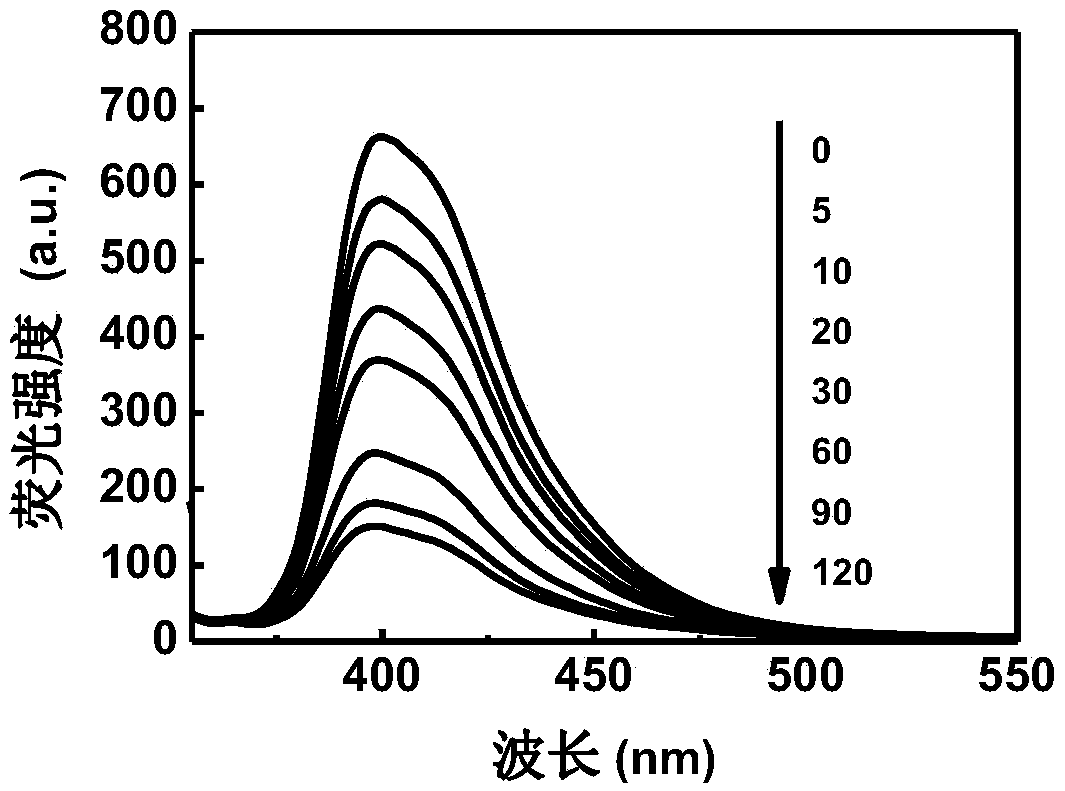

[0031] Dissolve 5mg of 9-(pyrene-1-yl)-9H-carbazole (PyCz) and 200mg of polystyrene (PS) together in 2ml of N,N-dimethylformamide (DMF), and seal it at room temperature Let the polystyrene (PS) swell for a period of time, then stir vigorously until the solid is completely dissolved, then add 600mg porogen (TX-100), and continue stirring vigorously at room temperature until the solution is uniform and transparent;

[0032] Inject the above-mentioned solution into a 2mL disposable plastic syringe, connect the open end with a stainless steel needle as the nozzle, connect it with the positive pole of the power supply, use aluminum foil as the receiving screen, connect it with the negative pole of the power supply, and apply 15kV between the nozzle and the receiving screen. voltage, set the advance speed of the syringe pump to 0.001mm / s, and conduct electrospinning under the condition that the receiving distance is 15cm, and prepare nanofibers containing porogen, and then receive th...

Embodiment 2

[0040] Example 2: 2mg 9-(pyrene-1-yl)-9H-carbazole (PyCz), 200mg polystyrene (PS) and 600mg porogen (TX-100) were dissolved together in 2ml N,N-bis In methylformamide (DMF) solvent, after sealing, place it at room temperature for a period of time to let the polystyrene swell, and then stir vigorously until the solution is uniform and transparent. Inject the above-mentioned solution into a 2mL disposable plastic syringe, connect the open end with a stainless steel needle as the nozzle, connect it with the positive pole of the power supply, use aluminum foil as the receiving screen, connect it with the negative pole of the power supply, and apply 18kV between the nozzle and the receiving screen. Voltage, set the advance speed of the syringe pump to 0.003mm / s, and conduct electrospinning under the condition that the receiving distance is 15cm, prepare nanofibers containing porogen, and then receive them on a quartz plate of 5mm×25mm×1mm on aluminum foil Utilization example Electr...

Embodiment 3

[0042] Example 3: 2mg 9-(pyrene-1-yl)-9H-carbazole (PyCz), 200mg polystyrene (PS) and 800mg porogen (TX-100) were dissolved together in 2ml N,N-bis In methylformamide (DMF) solvent, after sealing, place it at room temperature for a period of time to let the polystyrene swell, then stir vigorously until the solution is uniform and transparent, inject the above-mentioned solution into a 2mL disposable plastic syringe, The open end is connected to the stainless steel needle as the nozzle, connected to the positive pole of the power supply, and aluminum foil is used as the receiving screen, connected to the negative pole of the power supply, and a voltage of 15kV is applied between the nozzle and the receiving screen, and the advancing speed of the syringe pump is set to 0.003mm / s. Electrospinning was carried out at a distance of 15 cm, and nanofibers containing porogens were prepared.

[0043] Figure 7 For the polymer porous nanofibers prepared in the above-mentioned Example 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com