High-performance perovskite solar cell

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components and other directions, can solve the problems of low carrier recombination probability, low photoelectric conversion efficiency, poor film quality, etc., and the method is simple and low cost. , the effect of improving the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

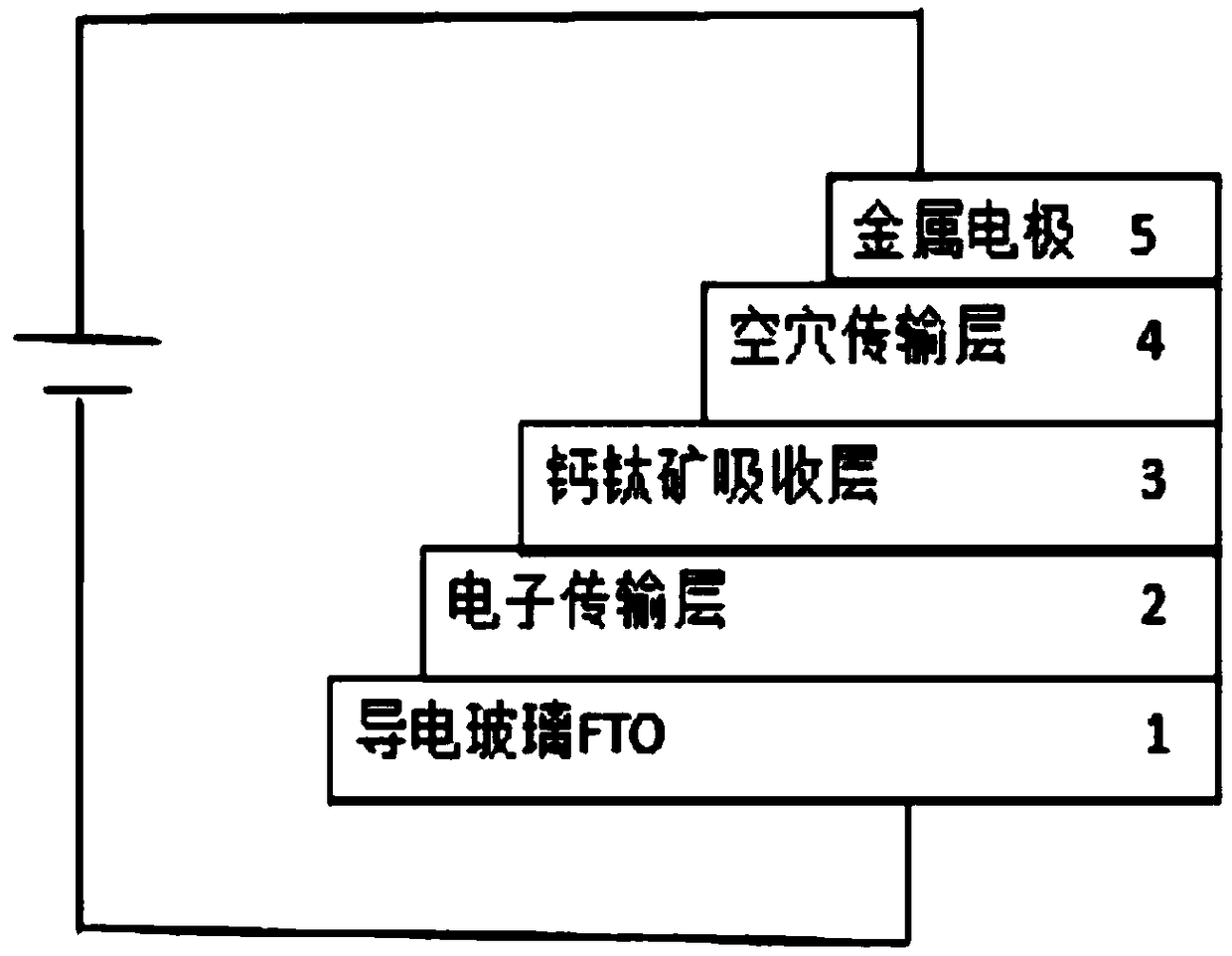

[0024] Such as figure 1 As shown, the high-performance perovskite solar cell structure of the present invention includes a conductive substrate 1 , an electron transport layer 2 , a perovskite light-absorbing layer 3 , a hole transport layer 4 and an anode layer 5 from bottom to top. The conductive substrate 1 is a transparent conductive substrate FTO, and the electron transport layer 2 is TiO 2 The mixed crystal electron transport layer, the perovskite light-absorbing layer 3 is a perovskite light-absorbing layer with additives, and the anode layer 5 is an Ag electrode.

[0025] The preparation method of the above-mentioned high-performance perovskite solar cell is as follows:

[0026] (1) FTO (tin oxide doped with F) conductive glass substrate is cleaned, blown dry with dry nitrogen, and carry out ultraviolet ozone pretreatment;

[0027] (2) Prepare TiO with a thickness of 60nm on a clean FTO conductive substrate 2 The dense thin film layer is the electron transport layer...

Embodiment 2

[0036] The preparation method of a kind of high-performance perovskite solar cell is as follows:

[0037] (1) FTO (tin oxide doped with F) conductive glass substrate is cleaned, blown dry with dry nitrogen, and carry out ultraviolet ozone pretreatment;

[0038] (2) Prepare TiO with a thickness of 60nm on a clean FTO conductive substrate 2 The dense thin film layer is the electron transport layer;

[0039] (3) methylammonium iodide and lead iodide are dissolved in N, in the N-dimethylimide, the concentration of methylammonium iodide and lead iodide is 1.2mol / L, then add acesulfame potassium, its The amount accounts for 8% of the total mass of the perovskite precursor solution, heating, stirring evenly, standing still for a period of time, filtering, and the filtrate is the precursor solution containing additives; on the surface of the prepared electron transport layer in step (2) Spin-coat the precursor solution, and place the prepared sample on a heating table at 50-200°C fo...

Embodiment 3

[0048] The preparation method of a kind of high-performance perovskite solar cell is as follows:

[0049] (1) FTO (tin oxide doped with F) conductive glass substrate is cleaned, blown dry with dry nitrogen, and carry out ultraviolet ozone pretreatment;

[0050] (2) Prepare TiO with a thickness of 60nm on a clean FTO conductive substrate 2 The dense thin film layer is the electron transport layer;

[0051] (3) Dissolve methylammonium iodide and lead iodide in N,N-dimethylimide, the concentration of methylammonium iodide and lead iodide is 1.2mol / L, then add sodium cyclamate , its consumption accounts for 14% of the total mass of the perovskite precursor solution, heating, stirring evenly, standing still for a period of time, filtering, and the filtrate is the precursor solution containing additives; the prepared electron transport layer in step (2) Spin-coat the precursor solution on the surface. After the spin-coating, place the prepared sample on a heating table and heat it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com