Cereal extruded puffed food and preparation technology thereof

A technology of puffed food and preparation process, which is applied in the directions of food ingredients containing natural extracts, food ingredients containing organic compounds, food ingredients, etc. Crispy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

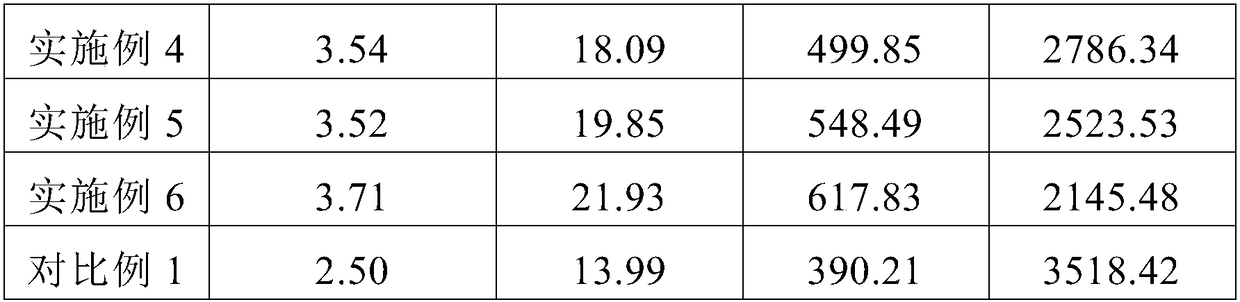

Examples

preparation example Construction

[0042] The preparation method of wheat flour is as follows: wash the wheat, drain the water, add 12% of the weight of the wheat to moisten the wheat, the temperature of the wheat is 28°C, the time of the wheat is 24h, and then use the Chopin experimental mill to grind the flour, first at 200r / The rotating speed of min is skin milled 3min, and the obtained wheat dregs of leather mill carries out 2 times of heart grinding, and each time of heart grinding is 4min, and the speed of the upper grinding roller of described heart grinding system during heart grinding is 325r / min, and the speed of lower grinding roller is 445r / min, finally get wheat flour and wheat bran.

[0043] α-amylase, with an enzyme activity of 240 U / g, food grade, was purchased from Tianjin Nuoao Enzyme Co., Ltd.

[0044] Saccharomyces cerevisiae, with an effective viable count of 20 billion CFU / g, was purchased from Guangzhou Weiyuan Biotechnology Co., Ltd.

[0045] The preparation method of yeast liquid: mix...

Embodiment 1

[0063] A preparation process for grain extrusion puffed food, comprising the following steps:

[0064] Ⅰ. Pretreatment: Mix wheat flour, cornstarch, and water, wherein the mass ratio of wheat flour, cornstarch, and water is 50:2:10, stir at 20°C at a speed of 25r / min for 15min, then use citric acid Adjust the pH value to 6, add α-amylase with 0.2% mass of the obtained mixture A, stir at 20° C. at a speed of 25 r / min for 15 minutes, and let it stand for 8 minutes to obtain mixture B;

[0065] Ⅱ. Mixing and deployment: add white granulated sugar and calcium carbonate to mixture B, wherein the mass ratio of the mixture B, white granulated sugar and calcium carbonate is 60:2:0.0005, stir at 20°C at a speed of 25r / min for 20min, After mixing evenly, a mixture is obtained;

[0066] Ⅲ. Extrusion molding: The above-mentioned mixture is extruded and extruded by a twin-screw extruder, and passes through three temperature zones in sequence. The temperatures of the first, second and thir...

Embodiment 2

[0071] A preparation process for grain extrusion puffed food, comprising the following steps:

[0072] Ⅰ. Pretreatment: Mix wheat flour, cornstarch, and water, wherein the mass ratio of wheat flour, cornstarch, and water is 50:2:10, stir at 20°C at a speed of 25r / min for 15min, and continue to add citric acid Adjust the pH value to 5, add 0.2% yeast liquid of the obtained mixture A, stir at 20°C at a speed of 25r / min for 15min, seal it, and perform anaerobic fermentation at 30°C for 8h to obtain mixture B;

[0073] Ⅱ. Mixing and deployment: add white granulated sugar and calcium carbonate to mixture B, wherein the mass ratio of the mixture B, white granulated sugar and calcium carbonate is 60:2:0.0005, stir at 20°C at a speed of 25r / min for 20min, After mixing evenly, a mixture is obtained;

[0074] Ⅲ. Extrusion molding: The above-mentioned mixture is extruded and extruded by a twin-screw extruder, and passes through three temperature zones in sequence. The temperatures of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com