Alkali-resistant aluminum alloy composite material and preparation method thereof

A composite material and aluminum alloy technology, which is applied in the field of alkali-resistant aluminum alloy composite materials and manufacturing, can solve problems such as poor wear resistance and easy damage to the alkali-resistant corrosion layer, and achieve good interface compatibility and interface wettability Good compatibility with the interface, good alkali corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

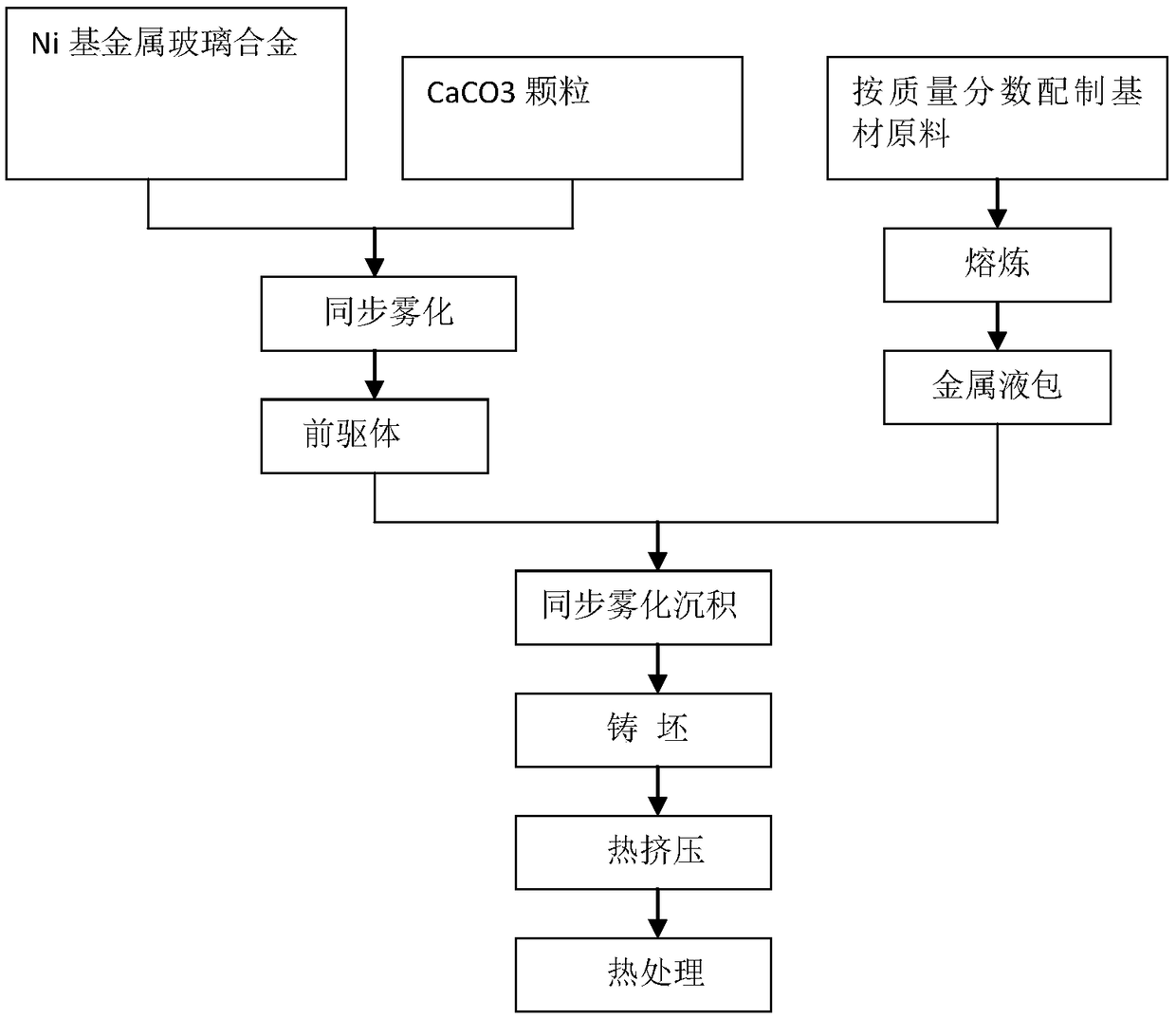

[0024] Embodiment 1: An aluminum-based composite material and additive manufacturing method for an alkaline corrosion-resistant drill pipe, the specific steps are as follows:

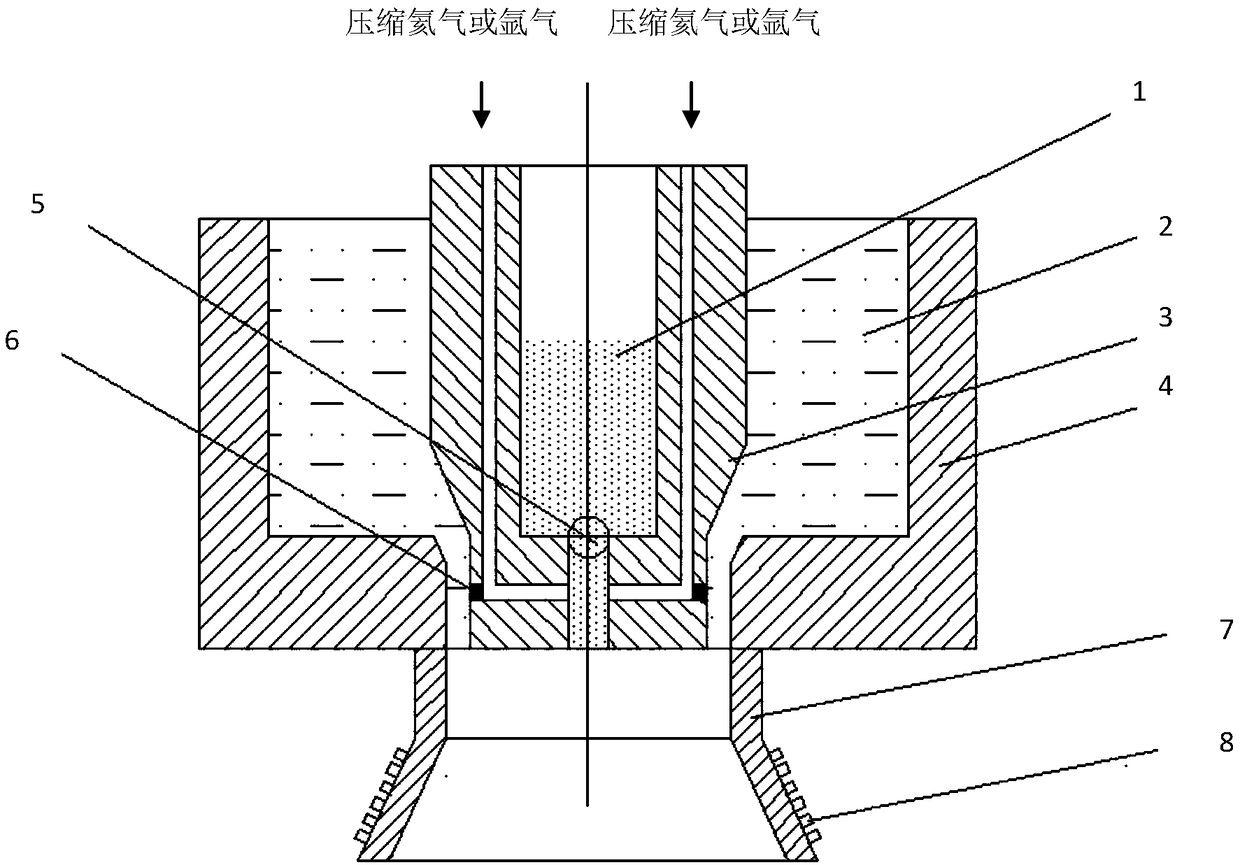

[0025] 1) Preparation of precursor: Prepare Ni, Nb, Ti, and Hf metals according to the atomic ratio to configure the raw materials, place them in a crucible melting furnace and heat them to melt under the protection of argon, and then inject the melt into the molten metal in the spray deposition machine package, while CaCO with a particle size of 10 μm 3 Fill into the solid fluidized conveyor; feed 3MPa high-pressure helium into the metal liquid bag and the solid fluidized conveyor respectively to let Ni 60 Nb 20 Ti 12.5 f 7.5 Liquid metal and CaCO 3 The particles are synchronously atomized to form solid-liquid mixed droplets, which are rapidly solidified under the action of the cooler at the lower end of the atomization chamber, and deposited on the substrate to obtain precursor particles with a pa...

Embodiment 2

[0030] Embodiment 2: An aluminum-based composite material and additive manufacturing method for an alkaline corrosion-resistant drill pipe, the specific steps are as follows:

[0031] 1) Preparation of precursor: Prepare Ni, Nb, Ti, and Hf metals according to the atomic ratio to configure the raw materials, place them in a crucible melting furnace and heat them to melt under the protection of argon, and then inject the melt into the molten metal in the spray deposition machine package, while CaCO with a particle size of 10 μm 3 Fill into the solid fluidized conveyor; feed 3MPa high-pressure helium into the metal liquid bag and the solid fluidized conveyor respectively to let Ni 60 Nb 20 Ti 12.5 f 7.5 Liquid metal and CaCO 3 The particles are synchronously atomized to form solid-liquid mixed droplets, which are rapidly solidified under the action of the cooler at the lower end of the atomization chamber, and deposited on the substrate to obtain precursor particles with a pa...

Embodiment 3

[0036] Embodiment 3: An aluminum-based composite material for an alkaline corrosion-resistant drill pipe and an additive manufacturing method, the specific steps are as follows:

[0037] 1) Preparation of precursor: Prepare Ni, Nb, Ti, and Hf metals according to the atomic ratio to configure the raw materials, place them in a crucible melting furnace and heat them to melt under the protection of argon, and then inject the melt into the molten metal in the spray deposition machine package, while CaCO with a particle size of 10 μm 3 Fill into the solid fluidized conveyor; feed 3MPa high-pressure helium into the metal liquid bag and the solid fluidized conveyor respectively to let Ni 60 Nb 20 Ti 12.5 f 7.5 Liquid metal and CaCO 3 The particles are synchronously atomized to form solid-liquid mixed droplets, which are rapidly solidified under the action of the cooler at the lower end of the atomization chamber, and deposited on the substrate to obtain precursor particles with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com