Carbon nanotube-aramid fiber far-infrared paper and preparation method thereof, and carbon nanotube far-infrared ray physiotherapy shoe sole lining

A carbon nanotube and far-infrared technology is applied in the fields of carbon nanotube-aramid far-infrared paper and its preparation, and the field of carbon nanotube far-infrared physiotherapy shoes sole lining, which can solve the problems of cumbersome preparation, physiotherapy functions need to be further improved, and structure complex issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

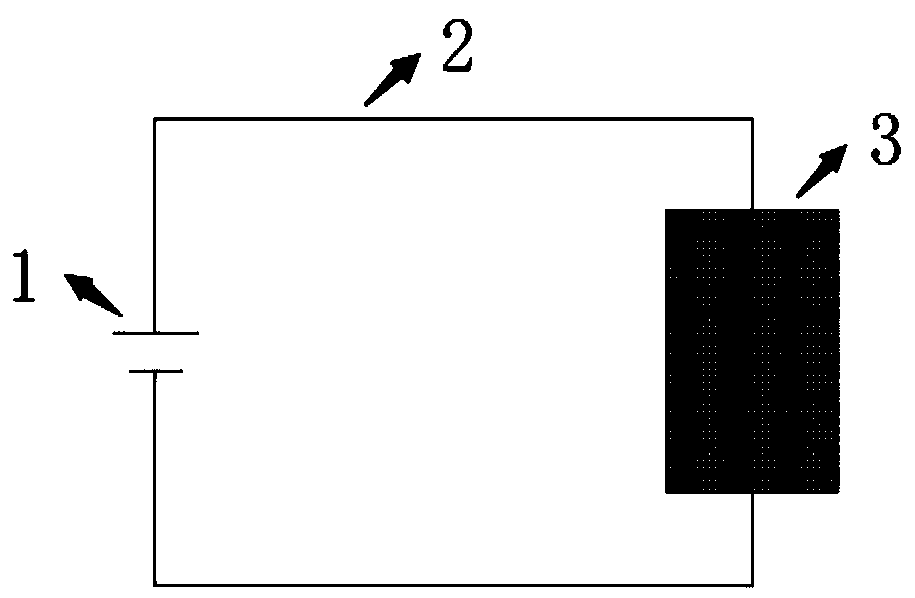

Image

Examples

preparation example Construction

[0021] The invention provides a kind of preparation method of carbon nanotube-aramid fiber far-infrared paper, comprising the following steps:

[0022] mixing the dispersion of para-aramid chopped fibers and the dispersion of para-aramid precipitated fibers, and beating to obtain aramid fiber slurry;

[0023] Mix the aramid fiber slurry with the carbon nanotube dispersion and reinforcing agent, coat the obtained aramid-carbon nanotube fiber slurry on filter paper, and then dry, roll and peel off the filter paper in sequence to obtain carbon nanotubes. Tube - Aramid Far Infrared Paper.

[0024] The invention mixes the dispersion liquid of the para-aramid chopped fiber and the dispersion liquid of the para-aramid precipitated fiber, and performs beating to obtain the aramid fiber slurry. In the present invention, the para-aramid chopped fiber is preferably mixed with the sodium dodecylbenzenesulfonate aqueous solution, then ultrasonically dispersed for 30-60 minutes, and then w...

Embodiment 1

[0031] Ultrasonic dispersion of 1.5g para-aramid chopped fibers in sodium dodecylbenzene sulfonate aqueous solution for 30min, cleaned with deionized water to obtain a dispersion of para-aramid chopped fibers; 2.5g para-aramid Ultrasonic dispersion of the para-aramid fibrid fiber in an aqueous solution for 30 minutes to obtain a dispersion of the para-aramid fibrid fiber; mix the above-mentioned dispersion of the para-aramid chopped fiber with the dispersion of the para-aramid fibrid fiber, and Beating for 40 minutes in a trough beater, controlling the beating concentration to be 5%, to obtain aramid fiber slurry;

[0032] 1.5g of carbon nanotubes are uniformly dispersed in ethanol solvent to obtain a dispersion of carbon nanotubes, and after mixing the dispersion of carbon nanotubes and aramid fiber slurry through an air collider, add 0.03g of ion Polyacrylamide and 0.03g carboxymethyl cellulose are used as a reinforcing agent to obtain a carbon nanotube-aramid fiber slurry, ...

Embodiment 2

[0035] Ultrasonic disperse 2.0g of para-aramid chopped fibers in an aqueous solution of sodium dodecylbenzene sulfonate for 30min, and clean them with deionized water to obtain a dispersion of para-aramid chopped fibers; 3g of para-aramid The precipitated fibers were ultrasonically dispersed in an aqueous solution for 30 minutes to obtain a dispersion of para-aramid fibrids; the dispersion of the above-mentioned para-aramid chopped fibers was mixed with the dispersion of para-aramid fibrids, and the Beating 40min in the type beater, control beating concentration is 6%, obtains aramid fiber slurry;

[0036] 2.0g of carbon nanotubes were uniformly dispersed in ethanol solvent to obtain a dispersion of carbon nanotubes, and after the dispersion of gained carbon nanotubes and aramid fiber slurry were mixed by an air collider, 0.03g of ionomer was added Acrylamide and 0.03g carboxymethyl cellulose are used as a reinforcing agent to obtain a carbon nanotube / aramid fiber slurry, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com