Magnetically separable ferroferric oxide/phosphorylatedgraphene composite nanomaterial

A technology of composite nanomaterials and iron tetroxide, which is applied in the field of nanomaterials to achieve the effects of realizing recycling, improving the efficiency of enrichment and recovery, and reducing the cost of enrichment and recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

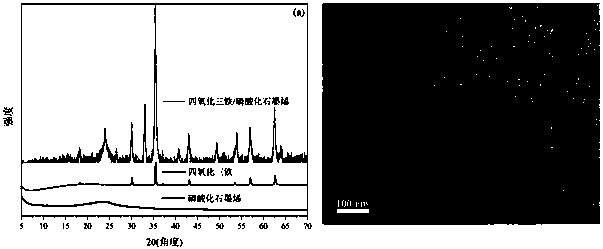

[0032] (1) Preparation of Magnetic Separable Fe3O4 / Phosphated Graphene Composite Nanomaterials

[0033] Disperse 1 g of graphene oxide into 150 mL of a mixed solution of anhydrous tetrahydrofuran and triethylamine with a volume ratio of 2, and sonicate in an ice-water bath to obtain a 6.67 mg / mL graphene oxide suspension. In an ice-water bath, 100 mL of anhydrous tetrahydrofuran containing 10 mL of phosphorus trichloride was added to the rapidly stirred graphene oxide suspension. Then the mixture was refluxed at 80 °C for 24 h, and after cooling, 500 mL of water was slowly added in batches. Centrifuge, wash and filter until the filtrate is clear, then add water to the filter cake and ultrasonically disperse it. The dispersion was hydrolyzed at 60 °C for 2 h. During the hydrolysis process, the pH of the solution was adjusted to 5-8 with 1 mol / L sodium hydroxide solution. After washing and filtering, it was ultrasonically dispersed in water, and then freeze-dried to obtain flu...

Embodiment 2

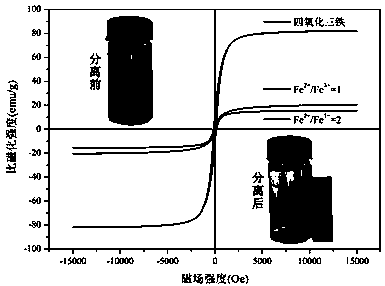

[0037] In Example 1, "disperse ferric chloride hexahydrate and ferric dichloride tetrahydrate in deionized water in a molar ratio of 1 to form a 0.02 mol / L mixed ion solution." Ferric trichloride hydrate and ferric dichloride tetrahydrate are dispersed in deionized water in a molar ratio of 0.5 to form a 0.02 mol / L mixed ion solution.” Other preparation conditions are the same as in Example 1, and the obtained magnetically The magnetic saturation strength of the isolated Fe3O4 / phosphorylated graphene composite nanomaterial is 15.6 emu / g, which can achieve magnetic separation within 15 minutes.

Embodiment 3

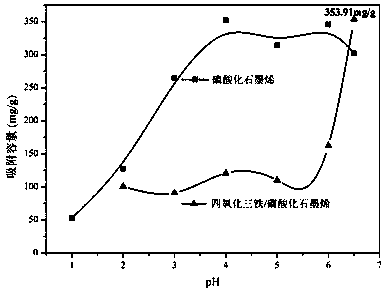

[0039] In Example 1, "2 mg magnetically separable ferric oxide / phosphorylated graphene composite nanomaterials were dispersed in 100 mg / L rare earth gadolinium ion solution." was replaced with "10 mg magnetically separable ferric oxide The tri-iron / phosphorylated graphene composite nanomaterial is dispersed in a 320 mg / L rare earth gadolinium ion solution." Other adsorption conditions remained unchanged, and its adsorption capacity was 353.18 mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com